Plastic recycling Cupro fiber Circular Economy Indorama spandex Achema 2022 Gopolyester Biomass Film Textile 16-12-2021 - Arhive

Plastic recycling Cupro fiber Circular Economy Indorama spandex Achema 2022 Gopolyester Biomass Film Textile

-Eastman Highlights Circular Economy and Other Areas as Drivers of Growth

Eastman expects to announce at least one additional circular economy project in the first half of 2022.

During its virtual and in-person 2021 Innovation Day on Dec. 7, Eastman Chemical highlighted areas that will help deliver growth through 2024. The circular economy was especially highlighted as a key opportunity.

Earlier this year, Eastman announced that it is moving forward with its circular economy project in Kingsport, Tenn., which includes construction of the world’s largest polyester material recycling facility and a Tritan polyester polymerization plant. The project is expected to begin producing at commercial quantities in 2023.

“Over the past several years, we have executed a strategy to position Eastman as a leading material innovation company. Central to our strategy is our compelling, innovation-driven growth model, which is succeeding in creating consistent, sustainable value for all our stakeholders,” said Mark Costa, board chair and chief executive officer. “We are leveraging our unique model to create value from disruptive macro trends, which we expect to be a strong contributor to Eastman’s growth over the next three years.”

Costa continued, “One area in particular that we are very excited about is our leadership position in the circular economy. Through our competitively advantaged molecular recycling capabilities, we are providing solutions for the plastic waste and climate crises while also creating a new vector of growth that has the potential to deliver greater than $450 million of adjusted EBITDA by 2026.”

Steve Crawford, executive vice president, technology and chief sustainability officer, discussed how Eastman is leveraging its growth model to accelerate and deliver sustainable innovations and create a competitive advantage.

-Indorama to establish third plant in India to expand spandex capacity14

Indorama India Private Limited (formerly called Indorama Industries Limited), which is engaged in the production and marketing of INVIYA brand of spandex since 2012, has solemnised the ground-breaking ceremony of its third plant (termed as P-3) at its existing site at Baddi in Himachal Pradesh recently.

The new plant will augment the spandex capacity of Indorama to 75 MT/day by the end of 2022, the company said in a media release.

INVIYA is well positioned to provide functional solutions to high end garments, accessories like elastics, tapes etc and hygiene products like diapers. Incidentally, Indorama is the only company in Indian subcontinent to produce elastomeric yarns meant for these applications (elastics/narrow fabrics/diapers).

INVIYA spandex is available in denier ranging from 10 to 1680 in different lustres to address the consumer needs across various segments. Apart from these, various cross functional teams of INVIYA work closely with customers to work out solutions to meet various requirements.

Spandex market demand is pegged at around 45,000 MTs in India and with a push from the government, this is slated to grow at CAGR of around 14-15 per cent.

Plastic recycling Cupro fiber Circular Economy Indorama spandex Achema 2022 Gopolyester Biomass Film Textile

-Asahi Kasei Celebrates 90th Anniversary of Bemberg™ Cupro Fiber and Launches Rebranding

Asahi Kasei is celebrating the 90th anniversary of its Bemberg™ cupro fiber business in 2021, and launching a rebranding to mark the occasion.

90th Anniversary

Overview of Bemberg™ cupro fiber

Bemberg™ is the brand name of the world’s only cupro fiber, which is manufactured by Asahi Kasei in Nobeoka, Miyazaki Prefecture, Japan. With its beautiful luster and smooth silky texture together with functional properties of moisture absorption/release and feeling cool to the touch, it is used around the world in various applications such as linings, ethnic garments, outerwear, and innerwear. Being made from cotton linter, a by-product of cottonseed oil production, as well as being biodegradable and compostable for circularity, Bemberg™ is an environmentally friendly material.

90-year history of Bemberg™

The Bemberg™ business has been advanced flexibly in accordance with social conditions and changing fashions. The history of Bemberg™ has been one of continually finding new applications and product developments in cooperation with partner companies sharing the same values throughout the process of procuring raw material, manufacturing raw yarn, processing yarn, weaving, knitting, and dyeing.

Ahead to the next century

In celebrating the 90th anniversary of its Bemberg™ business, Asahi Kasei is looking ahead to the next century by advancing efforts to improve the environment and provide solutions for society by implementing measures toward carbon neutrality by 2050, strengthening the traceability of raw materials, and developing technology to reduce the environmental burden across the entire supply chain. Although Bemberg™ is an uncommon material which accounts for only 0.02% of the world’s total fiber production, Asahi Kasei is pursuing value creation and sustainability together with its stakeholders as the only cupro fiber manufacturer.

Plastic recycling Cupro fiber Circular Economy Indorama spandex Achema 2022 Gopolyester Biomass Film Textile

-Achema 2022 Postponed to August

The leading trade fair for the process industry is scheduled to take place from August 22 to 26, 2022, at the Frankfurt exhibition center. Originally, Achema was scheduled from April 4 to 8, 2022. Given the increasing uncertainty caused by the new Corona variant, those responsible — after intensive discussion with the community and the Achema Committee — have decided to do so.

Frankfurt/Germany – “As a global meeting place for the process industry, we are looking with concern at the newly emerging travel restrictions,” said Thomas Scheuring, Managing Director of Dechema Ausstellungs-Gesellschaft. “Despite an extensive hygiene concept for Achema, which was originally planned for April 2022, we would like to enable our visitors and exhibitors to meet as carefree as possible on site after a two-year dry spell and the longing for an Achema to touch. We don’t see that happening in April 2022 at the moment and are therefore postponing Achema until the end of August.”

The organizers see the shift of four months to late summer 2022 as an opportunity to create an international Achema. “After many months of digital meetings, we want to fulfill the desire of exhibitors and visitors for a physical Achema with participants from all over the world,” explains Dr. Björn Mathes, deputy managing director of Dechema Ausstellungs-Gesellschaft. He says there needs to be an extensive exhibition program and the opportunity for personal contact for this.

After intensive discussions with partners and the Achema Committee, which represents the exhibitors, the decision was made in favor of Achema as a presence trade fair from August 22 to 26, 2022. With this early decision, Dechema also wants to give exhibitors planning security: After all, for them, a major event like Achema means long-term preparation and investment.

“Apart from the date, nothing will change at the planned Achema 2022,” is how Scheuring sums it up: Trendsetting technology and worldwide networking will characterize the world’s leading trade fair when manufacturers and service providers present their products and solutions for chemistry, pharmaceuticals, biotechnology, energy and the environment at the end of August 2022. Founders and young entrepreneurs will meet in the Start-up Area.

Plastic recycling Cupro fiber Circular Economy Indorama spandex Achema 2022 Gopolyester Biomass Film Textile

Fund II surpasses fundraising targets & extends Closed Loop Partners’ first venture fund strategy across sectors to build circular supply chains

Closed Loop Partners’ venture capital group––the Closed Loop Ventures Group––announced the successful close of its second fund, surpassing its $50 million target to scale breakthrough circular economy solutions across plastics & packaging, fashion, food & agriculture, and supply chain technology. The firm continues its pioneering position as a dedicated circular economy-focused capital provider, investing in sustainable and profitable solutions that reduce waste, increase operational and material efficiency, and protect the planet.

Closed Loop Partners’ second venture capital fund, Closed Loop Venture Fund II, is driven by the success of its Fund I. The strategy of both funds capitalizes on the growing need to shift away from inefficient, linear and extractive supply chains and toward healthier, waste-free circular systems. The Closed Loop Venture Fund II is strategically positioned within the firm’s broader ecosystem that includes growth equity, private equity and project-based finance, as well as the Center for the Circular Economy. The Ventures Group benefits from a broad range of investors including multinational corporations like Microsoft and GS Group, foundations like the Autodesk Foundation, and single and multi-family offices from across the United States, Asia and Israel.

“At Microsoft, we’re advancing a more sustainable and resilient way of producing and consuming products and services. The breakthrough solutions that the Closed Loop Ventures Group invests in help pave the way toward a more circular future, one that aligns with our vision of a zero waste world,” says Brandon Middaugh of Microsoft’s Climate Innovation Fund, an investor in Closed Loop Partners’ funds. “Our investment in the Ventures Group’s Fund II is a key part of our efforts toward our 2030 zero waste goals, driven by the innovators and emerging companies that help make this possible.”

“Venture capital plays a key role in accelerating the circular economy, seeding the next generation of solutions to overcome legacy take-make-waste systems, encourage innovation and help transformative companies scale,” says Taehong Huh, Managing Director of GS Futures, corporate venture arm of GS Group of Korea. “The Closed Loop Ventures Group is blazing a trail for some of the most innovative circular solutions in the market today, and we are proud to be investors in the Closed Loop Venture Fund II––supporting companies that advance the circular shift of our economic system.”

Plastic recycling Cupro fiber Circular Economy Indorama spandex Achema 2022 Gopolyester Biomass Film Textile

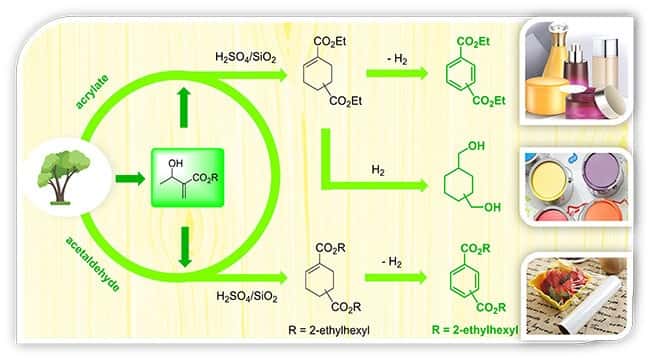

-Scientists propose new method for sustainable production of copolyester monomers with biomass

Poly (1,4-cyclohexylene dimethylene terephthalate-co-isophthalate) (PCTA) is an important copolyester that has been widely used in cosmetic containers, home appliances, and medical packaging.

Currently, PCTA is manufactured via polycondensation of cyclohexanedimethanol (CHDM), which is industrially produced from petroleum-derived xylene. To reduce the reliance on fossil energy, it’s needed to develop a more sustainable alternative way.

Recently, a research team led by Prof. ZHANG Tao, Prof. WANG Aiqin and Prof. LI Ning, in collaboration with Prof. WANG Feng’s group, from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) developed a sustainable route for the production of copolyester monomers with biomass.

This study was published in Angewandte Chemie International Edition on Nov. 30.

In this study, the researchers used plant-based acrylate and acetaldehyde as feedstocks, and produced PCTA monomer in an overall yield of 61%. The whole process included Morita-Baylis-Hillman (MBH) reaction, one-step dehydration/Diels-Alder reaction, and final Pd/C-catalyzed dehydrogenation.

Besides, they varied the final step to hydrogenation over Pd/C-Cu/Zn/Al dual-bed catalyst, and produced UNOXOLTM diol, which is another important monomer in coatings industry, in an overall yield of 67%.

Furthermore, the life cycle assessment implied that the newly-developed biomass-based routes had the potential to reduce carbon footprint.

“This study paves a new way for the production of renewable PCTA and also provides a new guidance for biomass conversion,” said Prof. LI.

Plastic recycling Cupro fiber Circular Economy Indorama spandex Achema 2022 Gopolyester Biomass Film Textile

-Neo-Pak launched a new line for the production of polymer packaging

The Neo-Pak company (Novosibirsk) has installed another technological line for the production of polymer packaging, which consists of a three-layer extrusion blow molding line, a Soma Optima2 flexo printing machine, a Lamiflex laminator and a slitter rewinder, the Novosibirsk government said in a statement.

It is expected that the implementation of the project will increase the market share for flexible packaging in the Siberian Federal District, the Urals and neighboring countries (Kazakhstan, Uzbekistan, etc.), for packages – throughout the Russian Federation and the CIS, create additional jobs (46 units) and to increase the plant’s capacity by 40%.

The Neo-pack company in October 2020 received the approval of a loan for 250 million rubles. within the framework of the Industrial Development Fund (IDF) “Development Projects” program. It was planned to double the production of flexible polymer packaging and bags, including for the distribution of goods from online stores.

The first stage of production with investments of 251.2 million rubles and a capacity of 6 thousand tons of flexible packaging per year was launched in the second quarter of 2019, reaching full capacity by 2026.

According to MRC’s ScanPlast report, Russia’s estimated PE consumption totalled 1,868,160 tonnes in the first nine months of 2021, up by 18% year on year. Shipments of all grades of ethylene polymers increased.

The Neo-Pak company was founded in 2009 in Novosibirsk. Today, the production capacity of Neo-Pak is 18 thousand km of printing per month and 700 tonnes of film per month. The number of employees of the company is about 200 people, the occupied area is 12,000 m.

Plastic recycling Cupro fiber Circular Economy Indorama spandex Achema 2022 Gopolyester Biomass Film Textile

-US textile-apparel imports from Turkey rise 50% till October ’21

Turkey-US trade is witnessing record high figures since the beginning of this year. US textile-apparel imports from Turkey registered $2.370 billion in the first ten months of this year, which is a nearly 50 per cent increase over imports of $1.586 billion in the same months of 2020, according to data from the Office of Textiles and Apparel (OTEXA).

Category-wise, US apparel imports from Turkey rose by a sharp 62.39 per cent to $702.627 million, compared to $432.681 million during January-October 2020. While non-apparel textile imports rose 44.66 per cent to $1.667 billion in January-October 2021, over $1.252 billion in the comparative period of last year.

This increase in textile-apparel export by Turkey, is in line with the growth in its overall exports to the US that have increased by 45 per cent year-on-year during January-November this year to $13.2 billion, according to the Turkey-U.S. Business Council. On the other hand, Turkey imported $11.7 billion of goods from the US during the same period.

Plastic recycling Cupro fiber Circular Economy Indorama spandex Achema 2022 Gopolyester Biomass Film Textile

Plastic recycling Cupro fiber Circular Economy Indorama spandex Achema 2022 Gopolyester Biomass Film Textile