Plastic-waste – PET-Recycling – Upcycle-car 06-06-2022 - Arhive

Plastic-waste – PET-Recycling – Upcycle-car

-Agilyx is rising to the mixed waste plastic challenge

Faced with the ever-mounting problem of plastic waste, consumers, organisations and governments around the world have called for industry solutions. While recycling can offer an answer, not all plastics can simply be recycled. And in fact, only around 10% of waste plastics are recycled today worldwide. Chemical recycling company Agilyx is working to change that. “We’re trying to do something about a waste problem,” said the company’s chief commercial officer, Carsten Larsen. “To enable a circular model that allows plastic to be used and recycled, again and again.”

Founded almost two decades ago, Agilyx can rightly be viewed as one of the pioneers of what today is known as chemical – or alternatively as advanced, feedstock or even molecular – recycling. Chemical recycling makes it possible to convert even hard-to-recycle mixed waste plastics into low-carbon feedstock that can be used to make new raw materials that can be turned into plastics.

While the premise is extremely promising, in practice there are still hurdles to be overcome. The technology developed by Agilyx involves a process called pyrolysis and is not entirely uncontroversial. Plastic-waste – PET-Recycling – Upcycle-car

Environmental groups have denounced it, calling it polluting, energy intensive and even just a fancy way of saying that these waste streams are simply being incinerated. Proponents, on the other hand, point to the advantages it offers, particularly the ability to increase the recycling of plastics unable to be recycled with traditional recycling processes.

-Hyosung to Present Its Ocean Protection Initiative at Outdoor Retailer

Hyosung will present its Ocean Protection Initiative at the summer edition of the Outdoor Retailer trade show in DenverJune 9–11.

The South Korea–based fiber manufacturer that provides innovations and solutions to the textile industry aims to turn ocean trash into treasure with this initiative, which begins with the development of Hyosung’s MIPAN regen ocean nylon and regen ocean polyester, both made with ocean waste.

MIPAN regen ocean is Global Recycled Standard certified, made from 100 percent recycled nylon made from discarded fishing nets and other reclaimed nylon waste. Hyosung’s process to produce the yarn includes collection, chemical recycling and creation. Hyosung awaits its Ocean Bound Plastic certification in the near future. The OBP certification was created to transparently certify that plastic waste was properly collected and managed. Plastic-waste – PET-Recycling – Upcycle-car

Hyosung will also present a broad assortment of fabrics and concept garments at the Outdoor Retailer Summer Market that were developed by Hyosung’s Fashion Design Center to help developers and designers conceive garments made with innovative fibers, including creora regen, a GRS-certified 100 percent recycled spandex; creora bio-based spandex made with 30 percent dent corn; MIPAN regen robic, 100 percent recycled high-tenacity nylon; and regen xanadu, a mechanical-stretch fiber made from a blend of PET and corn-based materials.

“Cleaning up our oceans is of critical importance to Hyosung and many of our brand partners,” said Hyosung Global Marketing Director—Textiles Mike Simko. “Our ocean-based recycled-fiber offering will allow brands to develop eco-friendly products that align with their sustainability needs and also help provide them with a meaningful story their consumers can connect with.”

-How automakers upcycle waste into car parts

A brief look into the car industry’s pursuit of sustainable materials

A brief look into the car industry’s pursuit of sustainable materials

With the rising awareness of climate change, more and more sectors are looking into sustainability, the process of turning environmentally unfriendly materials into usable items. Plastic-waste – PET-Recycling – Upcycle-car

The auto industry, being one of the major sources of greenhouse gas emissions, is no exception to this rule. From reclaimed wood to seat covers made from plastic bottles, the auto industry is working to turn otherwise landfill material into viable alternatives for other environmentally harmful resources.

Below are some ways the industry has succeeded in turning trash into treasure alongside a few they are actively pursuing.

Recycled plastic: From bottles to seats

Plastic waste, specifically polyethylene terephthalate (PET), is one of the biggest environmental hazards of modern times. Used to make single-use items such as shopping bags, soda bottles and straws, they are hard to dispose of and take an estimated 500 years to disintegrate (it still remains as micro or nano plastic).

National Geographic speculated that of the 8.3 billion metric ton of plastic humanity has created in the last six years, 6.3 billion metric ton have become plastic waste. Only nine per cent of which has been recycled. The vast majority—79 percent—is accumulating in landfills or sloughing off in the natural environment as littre.

The most common way carmakers recycle plastic is by turning them into interior upholstery. German automaker Audi is working on seats that are made with yarn produced from 89% ground up PET bottles. Conversely, American auto giant Ford already uses Repreve on some of their cars, which is a hybrid fibre made from recycled plastic water bottles and post-industrial waste.

-If nothing is done, humanity will produce three times more plastic waste in 2060

Plastic production and waste will increase sharply by 2060, even if strong framework measures are taken at the global level, warns this Friday, June 3 the OECD, while the UN recently launched negotiations to fight against this contamination.

“Significant threat to human health”: microplastics are also in the air

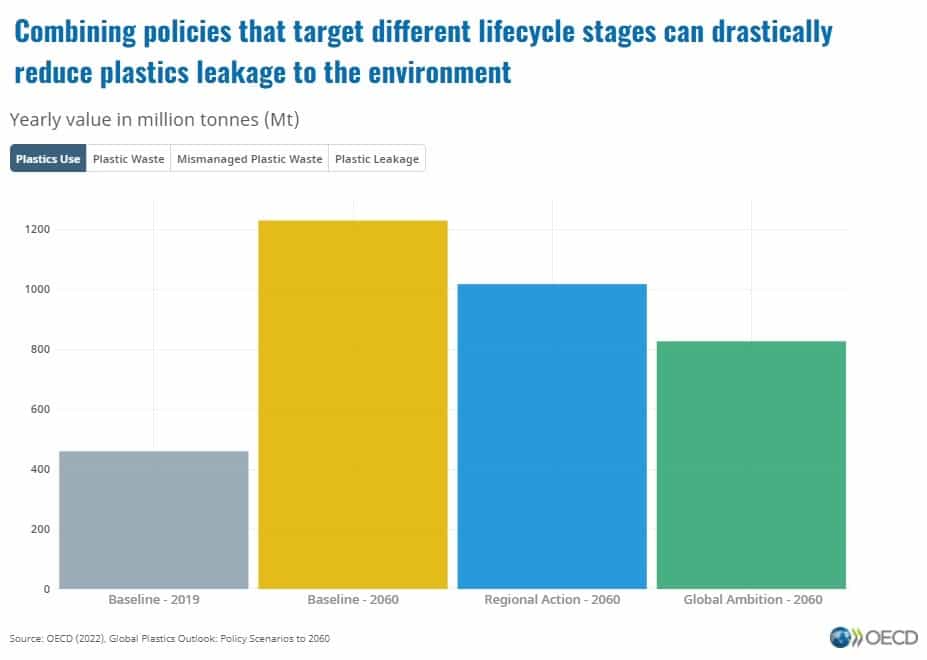

If nothing is done, the production of plastic will almost triple compared to 2019, from 460 million tonnes to 1,231 million tonnes, and that of plastic waste will increase in the same proportions, from 353 to 1,014 million tonnes. , according to this report on “Global Plastics Perspectives: Policy Scenarios to 2060”.

The UN launched negotiations in early March for a global treaty against plastic pollution, a scourge that threatens the environment and contributes to the collapse of biodiversity. Plastic-waste – PET-Recycling – Upcycle-car

But the finalization of a text is not expected before 2024. The hundreds of millions of tons of waste produced each year, which degrades into microplastics, are found in all the oceans of the globe, in the sea ice, in the bodies of humans and animals, and even in air sampled from mountaintops.

Two scenarios

The OECD is evaluating two scenarios with reinforced measures covering the entire life cycle of plastics (production/use/recycling or disposal), as provided for in the mandate of the negotiators of the future international treaty.

The first scenario “regional action” provides for differentiated commitments by country, with more ambitious measures for those in the OECD, which are wealthier. The second, “global ambition”consider “a set of very rigorous measures intended to reduce global plastic discharges to a level close to zero by 2060”. But even in these two scenarios, the use of plastics and the production of waste are increasing sharply.

-Taking PET Recycling To The Next Level

Chains become smaller molecules

Evonik is building a platform technology for recycling of various polymers. Mechanical recycling is usually the first choice, supported by Evonik´s range of process chemicals. To date, the plastic polyethylene terephthalate (PET) has a very successful tradition of being mechanically recycled. The collected bottle grade PET is shredded, cleaned, melted down, and once again moulded into bottles. However, this process cannot be used with other PET grades, which are dirty, carry complex additives, or simply are at their life cycle end with regard to mechanical recycling.

Evonik is working to develop processes for these PET grades — and is thus making it possible to recycle entirely new material flows. The process development for these PET grades has already made good progress. In terms of the chemistry involved, this process is a transesterification with alkoxide catalysts: The PET raw material is combined with an alcohol and the catalyst and is then treated thermally. The resulting reaction produces a terephthalic ester and ethylene glycol. These compounds can be then used later for repolymerization and for the production of specialty chemicals. Plastic-waste – PET-Recycling – Upcycle-car

-Global Plastics Outlook: Policy Scenarios to 2060

The amount of plastic waste produced globally is on track to almost triple by 2060, with around half ending up in landfill and less than a fifth recycled, according to a new OECD report. Plastic-waste – PET-Recycling – Upcycle-car

Global Plastics Outlook: Policy Scenarios to 2060 says that without radical action to curb demand, increase product lifespans and improve waste management and recyclability, plastic pollution will rise in tandem with an almost threefold increase in plastics use driven by rising populations and incomes. The report estimates that almost two-thirds of plastic waste in 2060 will be from short-lived items such as packaging, low-cost products and textiles.

“If we want a world that is free of plastic pollution, in line with the ambitions of the United Nations Environment Assembly, we will need to take much more stringent and globally co-ordinated action,” OECD Secretary-General Mathias Cormann said. “This report proposes concrete policies that can be implemented along the lifecycle of plastics that could significantly curb – and even eliminate – plastic leakage into the environment.”

The report (available as a preliminary version ahead of its full publication later this year) projects global plastics consumption rising from 460 million tonnes (Mt) in 2019 to 1,231 Mt in 2060 in the absence of bold new policies, a faster rise than most raw materials. Growth will be fastest in developing and emerging countries in Africa and Asia, although OECD countries will still produce much more plastic waste per person (238 kg per year on average) in 2060 than non-OECD countries (77 kg).

Globally, plastic leakage to the environment is seen doubling to 44 Mt a year, while the build-up of plastics in lakes, rivers and oceans will more than triple, as plastic waste balloons from 353 Mt in 2019 to 1,014 Mt in 2060. Most pollution comes from larger debris known as macroplastics, but leakage of microplastics (synthetic polymers less than 5 mm in diameter) from items like industrial plastic pellets, textiles and tyre wear is also a serious concern.

The projected rise in plastics consumption and waste will come despite an expected increase in the use of recycled plastic in manufacturing new goods as well as technological advances and sectoral economic shifts that should mean an estimated 16% decrease by 2060 in the amount of plastic required to create USD 1 of economic output. Plastic-waste – PET-Recycling – Upcycle-car

The share of plastic waste that is successfully recycled is projected to rise to 17% in 2060 from 9% in 2019, while incineration and landfilling will continue to account for around 20% and 50% of plastic waste respectively. The share of plastic that evades waste management systems – ending up instead in uncontrolled dumpsites, burned in open pits or leaking into the soil or aquatic environments – is projected to fall to 15% from 22%.

The new report builds on the OECD’s first Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options, released in February 2022. That first report found that plastic waste has doubled in two decades, with most ending up in landfill, incinerated or leaking into the environment. Since that report release, UN member states have pledged to negotiate a legally binding international agreement by 2024 to end

Plastic-waste – PET-Recycling – Upcycle-car