Plastic-waste-recycling -Oxygen-barrier 29-03-2022 - Arhive

Plastic-waste-recycling -Oxygen-barrier

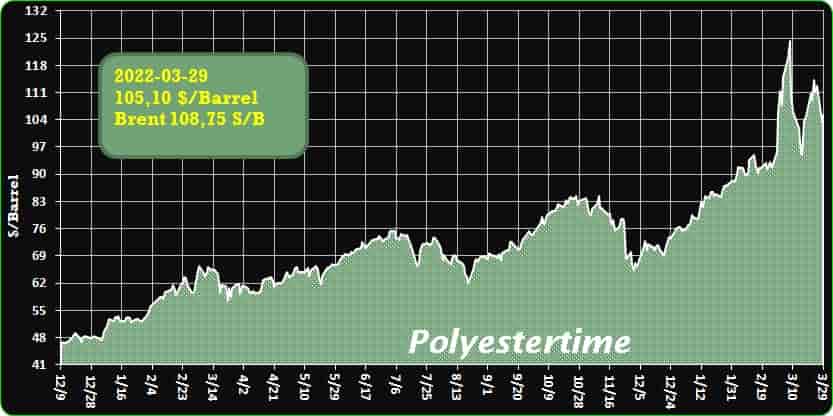

Crude Oil Prices Trend

-Consortium to Chemically Recycle 1-Million-Tons of Plastic Waste Annually into Feedstock

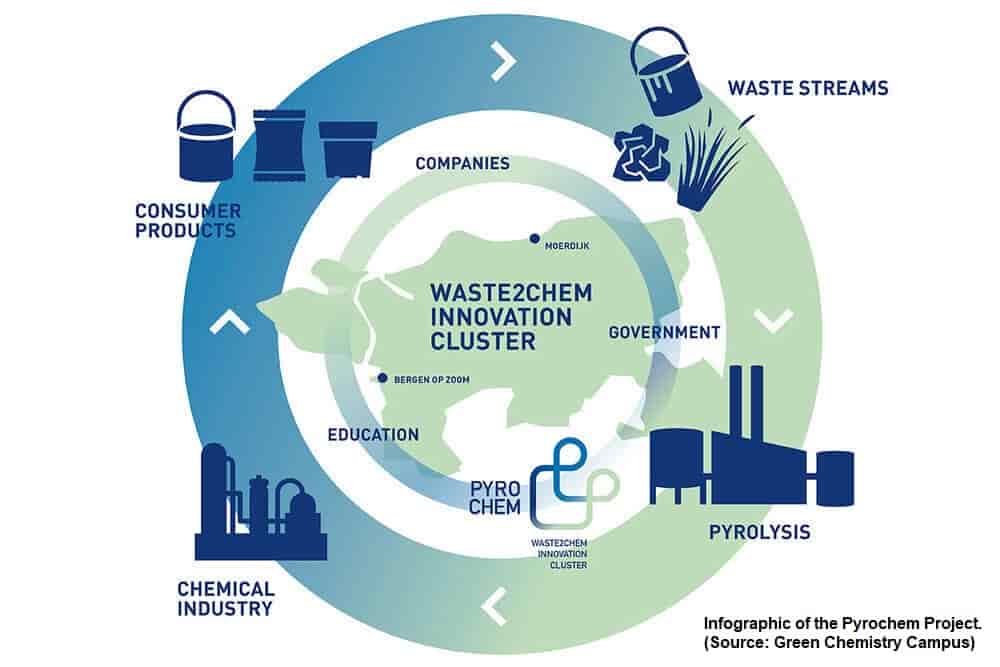

The Pyrochem Project aims to process 1 million tons of waste plastic into feedstock for the chemical industry from 2030 onwards. With this project, the project partners intend to reduce 1.7 million tons of CO2-eq annually and save 550 kilotons of petroleum.

West Brabant/The Netherlands – Much plastic waste such as agriculture foil or potato chips bags cannot be recycled now because it is too dirty or consists of several layers. The Pyrochem project aims to make the chemical industry more sustainable by optimizing and scaling up the chemical recycling of plastic waste and the pyrolysis of other (biomass) residual flows. The ambition: to process 1 million tons of waste plastic into feedstock for the chemical industry from 2030 onwards.

Pyrolysis: chemical recycling by heating in the absence of oxygen

Plastic waste that is currently unsuitable for recycling is often too polluted, such as agriculture foil, or consists of multiple layers such as bags for potato chips or coffee. In the Netherlands alone, we are talking about 629 ktons of plastic waste annually. At the moment this is incinerated, producing energy; a very low-grade form of waste processing. Plastic-waste-recycling -Oxygen-barrier

There is a technology that can process contaminated plastic – but also other (biomass) waste streams – to a high standard: pyrolysis. By means of heating in the absence of oxygen, these waste streams are processed to circular or bio-based building blocks that the chemical industry can use to make new products. Pyrolysis technology is still under development, but successes have already been achieved, for example in the ‘Pyrolyseproeftuin Moerdijk’. The Pyrochem project partners will now scale up the technology and further develop the value chain.

Pyrochem: Waste2Chem Innovation Cluster

The Pyrochem project partners want to make the chemical industry more sustainable by optimizing and scaling up the chemical recycling of plastic waste and the pyrolysis of other (biomass) residual flows. Plastic-waste-recycling -Oxygen-barrier

In the Pyrochem project, Waste4me will be designing a demonstration plant with a capacity of 35 kilotons. In addition, the project partners create a Waste2chem open innovation cluster. Here, SMEs can make use of the facilities of the Pyrochem project partners on favorable terms and use the network in order to optimize their pyrolysis technology and work together on roadmaps towards market introduction.

-SABIC part of recycled-content plastic packaging effort

Partnership introduces recycled-content polyethylene bag for frozen and chilled seafood products Plastic-waste-recycling -Oxygen-barrier

Global petrochemical firm SABIC says it has leveraged its ties with Polivouga, a maker of flexible film products with operations in Portugal, to help develop what it calls “the world’s first frozen food packaging solution using SABIC’s certified circular polyethylene from feedstock sourced from ocean-bound plastic.”

SABIC says the project has been designed to use post-consumer plastic scrap “recovered from areas up to 50 kilometers (31 miles) inland from waterways,” thus fitting an outside certification body’s definition of “ocean-bound.”

The project’s third collaborator is the Spain-based Nueva Pescanova Group, which operates in the fishing, farming, processing and marketing of fresh, chilled and frozen seafood products sector.

The collected plastic scrap is converted using what SABIC calls “an advanced recycling” process to produce the company’s certified circular polymers – SABIC® LLDPE (linear low-density polyethylene) and LDPE (low-density polyethylene). Further processing by Polivouga yields flexible packaging film used by Nueva Pescanova in its frozen seafood packaging bags. Plastic-waste-recycling -Oxygen-barrier

“This is an exciting circular packaging solution for us, since it demonstrates how used plastic that has the potential to end up in our oceans, can be brought back into a circular material stream to be converted into high quality food packaging,” says Sami Al-Osaimi, a vice president with SABIC.

Comments Ignacio González, CEO of the Nueva Pescanova Group, “With this initiative, we will prevent this plastic waste from reaching the marine environment, giving them a new life. We have set ourselves the goal of making 100 percent of our packaging recyclable by 2025 and, through this action, we will be one step closer to achieving this.”

The ocean-bound designation is certified under the Zero Plastic Oceans program and the International Sustainability & Carbon Certification (ISCC) PLUS chain of custody, says SABIC. That means the material flow is controlled and tracked from the ocean-bound plastic to the final packaging “following a set of predefined and transparent rules,” according to the company. Plastic-waste-recycling -Oxygen-barrier

–Consortium-to-Chemically-Recycle 1-Million-Tons of Plastic-Waste Annually into Feedstock

–SABIC part of recycled-content-plastic-packaging effort

–Eramet reports progress on battery-recycling-plant

–MOL-unit lays cornerstone of propylene-plant-in-Tiszaujvaros

–Sinopec suspends discussions with Sibur on investment in new gas-chemical-plant-in-Russia

–Hubergroup launches new oxygen-barrier-coating for flexible–packaging

–Ukraine-Russia: how the crisis could reshape petrochemicals-demand

-Meet the company building Europe’s first fossil-free-plastics-plant

Plastic-waste-recycling -Oxygen-barrier