PlasticRecycling Resinprices Cellulosicfiber 04-05-2021 - Arhive

PlasticRecycling Resinprices Cellulosicfiber

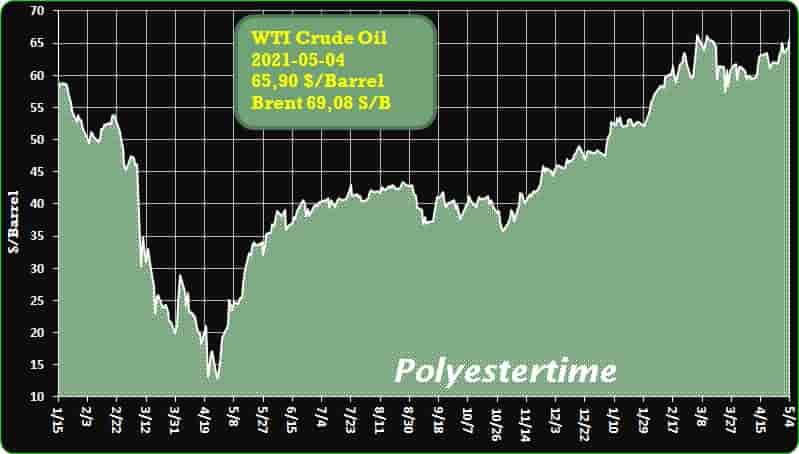

Crude Oil Prices Trend

-Expanded Line of Anti-Scratch Additive Masterbatches for PET

Ampacet’s two new additions to the ScratchShield line reportedly minimize the appearance of scuffs and scratches in preforms, bottles and a range of PET packaging.

Two new products targeted to PET preforms, bottles and other PET packaging have been added by Ampacet to its portfolio of ScratchShield additive masterbatches that help to protect plastic products against scratch and abrasion without impacting gloss or mechanical properties of the resin.

The new ScratchShield masterbatch additives are said to minimize the appearance of scuffs and scratches in preforms, bottles and a range of PET packaging without the need to apply a surface coating. These additives are also said to significantly improve the demolding of preforms, while offering protection from guiderails and conveyor systems in the manufacturing process. The two ScratchShield products are also said to help reduce scrap, the need to regrind scratched bottles and cleanup associated with lubricant sprays.

Brückner Maschinenbau, based in Siegsdorf, Germany, is the world market leader for large production lines for the manufacture of a wide variety of flexible plastic films, used as high-quality packaging materials and in technical applications. In terms of incoming orders, the past fiscal year was the second most successful in the company’s history. More than 45 lines sold by the end of 2020 (2019: more than 30) mean an order intake of almost 800 million euros, a significant increase compared to the previous year (approx. 500 million euros). As the new orders will only become relevant for sales in the following year, a significant increase in sales to over 550 million euros is expected for 2021 (2020: around 400 million).PlasticRecycling Resinprices Cellulosicfiber

One reason for the very pleasing business development is certainly that topics such as hygiene and food safety have become much more important in the packaging sector worldwide – and particularly in Asia. In addition, food retailing and mail-order trade have recorded international growth. This also increased the demand for Brückner film stretching lines, on which the highest quality packaging films are produced, and also for the corresponding services. The outlook for the next few years also gives cause for optimism. Stefan Neumann, Chief Financial Officer: “Our order backlog extends well into 2023. In addition, we are currently pleased about two major orders from China.”

-TECHNOLOGY PROFILE: PRODUCING POLYLACTIC ACID FROM CORN

Polylactic acid (PLA, polylactide; Figure 1) is a thermoplastic aliphatic polyester that is derived from a number of renewable starting materials, such as starch and sugarcane, via bacterial fermentation.

PLA is semicrystalline or amorphous, rigid, resilient and an ultraviolet-light-resistant material, with similar characteristics to common petrochemical industry plastics, such as polyethylene, polypropylene and polystyrene. PLA is used in plastic films, bottles and biodegradable medical devices. It figures among the most highly consumed bio-based plastics worldwide. PlasticRecycling Resinprices Cellulosicfiber

PLA rapidly absorbs moisture from the atmosphere and is also temperature-sensitive (storage temperatures should be below 122ºF). In order to preserve PLA properties and characteristics, exposure to ambient (undried) air should be minimized. PLA is usually delivered in moisture-resistant containers, including foil-lined boxes, which can prevent moisture regain during shipping and storage. PLA is mainly used in packaging, textiles, nonwoven fabrics, electronics, automotive parts, medical devices and cutlery. Packaging is the largest application market for PLA, and will likely grow as new heat-resistant PLA blends are developed.

-The “3R” decree finally published

Structuring, this text had been awaited for several months by professionals.

An essential part of the Agec law on the circular economy, the “3R” decree (Reduction, Reuse, Recycling) is finally published in the JO

These main quantified objectives, which will undoubtedly shape the contours of the plastic packaging industry in the years to come, are the same as in the version which was put out for consultation at the start of the year. PlasticRecycling Resinprices Cellulosicfiber

As of December 31, 2025, “all marketers of single-use plastic packaging” must have reduced their use of plastic by 20% compared to 2018, of which at least 50% obtained by recourse to reuse and reuse (Article 2).

With the reduction, reuse or even the use of recharging devices, the substitution of single-use plastic by other materials is part of the arsenal of actions that can be cited, but the text clearly emphasizes the need to carry out a rigorous Life Cycle Assessment (LCA) for a real reduction of environmental impacts …

-NEW DEMONSTRATION PLANT FOR CELLULOSIC TEXTILE FIBERS

A new demonstration plant will significantly scale up production of sustainable textile fibers made from cellulosic raw materials. TreeToTextile AB (Stockholm, Sweden; www.treetotextile.com), jointly owned by H&M Group, Inter IKEA Group, Stora Enso and LSCS Invest, has piloted a production technology to efficiently regenerate cellulose from bio-based sources, creating staple fibers that can be used in apparel, bedding and other textile applications. PlasticRecycling Resinprices Cellulosicfiber

The process dissolves wood pulp in a cold alkaline solution, resulting in a cellulosic solution that can be spun into long threads of fibers. After washing, fibers are cut into staple fibers and can be passed to downstream yarn-spinning processes. Notably, the system recycles all process chemicals and water. “When compared to conventional viscose production, according to our estimations the TreeToTextile process will consume at least 33% less energy, 70% less chemicals and 80% less water,” says Sigrid Barnekow, TreetoTextile CEO.

-The Single-use Plastics Directive: what next, and when?

In the run up to OUTLOOK 2021 Gil Stevens, EDANA’s External Relations & Sustainability Director, spoke with Haydn Davis of Sustainable Nonwovens, providing a preview of the suite of new online facilities which will enable participants to truly capitalise on attendance. PlasticRecycling Resinprices Cellulosicfiber

They also discussed the presentation Gil will give on the morning of April 22nd, on the Single-use Plastics directive, outlining the changes in store for producers and the wider implications for the industry.

A number of key questions remain for producers, including the very definition of a plastic, the timeline for labelling implementation, and language requirements in individual member states.

-Berry Global strikes polyolefins deal with Borealis

Berry Global has announced an agreement with Borealis for access to the latter’s first volumes of the in-demand circular polyolefins produced from its chemical recycling process. PlasticRecycling Resinprices Cellulosicfiber

This deal adds to Berry’s previously announced access to the 600 million pounds of post-consumer recycled (PCR) content it will have access to by 2025.

The polyolefins from Borealis are obtained by advanced recycling, enabled by the adoption of new chemical recycling technologies, of post-consumer plastic waste not suitable for traditional recycling.

These processes make it possible for material that would otherwise be discarded as waste and destined for incineration or landfill to be used as feedstock for production of polyolefins that fulfill the most stringent quality requirements.

“Investments in chemical recycling with partners like Borealis are critical to Berry and our customers as we collaborate across the value chain to solve the global commitment achieving net-zero emissions by 2050,” said Jean-Marc Galvez, President of Berry’s Consumer Packaging International Division.

-Customer Trials Start on ‘World’s First’ Recyclable PE-based Blister Packaging

Amcor’s AmSky eliminates PVC in healthcare packaging, which can be problematic to recycle by conventional methods, with polyethylene (PE) thermoform blister and lidding film. PlasticRecycling Resinprices Cellulosicfiber

Amcor has announced that it is beginning customer trials of what it is calling the world’s first recyclable polyethylene-based thermoform blister packaging. Designed to meet the regulatory requirements of pharmaceutical packaging, the product “creates a more sustainable alternative for the most in-demand healthcare packaging type,” said Amcor. This innovation also achieves up to a 70% reduction in the carbon footprint compared with packaging alternatives currently on the market.

AmSky replaces PVC in the packaging with polyethylene (PE) thermoform blister and lidding film. PVC can make packaging recycling more difficult or contaminate other materials if consumers attempt to recycle it, according to Amcor.

Noting that the company generates nearly $2 billion in annual sales in the healthcare market, “this new blister packaging solution will significantly enhance the ability of healthcare and pharmaceutical brands to put sustainability at the heart of their businesses,” said Peter Konieczny, Chief Commercial Officer.

-McDermott wins contract for Michelin chemical recycling project

US engineering firm McDermott International has been awarded a front-end engineering design (FEED) contract from Michelin Group for the construction of a plastic waste recycling plant.

The project will industrialise, for the first time, “an innovative plastic recycling process” which produces regenerated styrene from polystyrene, said McDermott in a 28 April statement. PlasticRecycling Resinprices Cellulosicfiber

The company did not elaborate on the recycling technology or the whereabouts of the plant, but said the regenerated styrene produced by the unit will be used in the production of synthetic rubber for tires and polystyrene.

However, McDermott’s said its office in Brno, the Czech Republic, will execute the work, which is expected to be completed in third quarter 2021.

According to McDermott, the “groundbreaking process” will advance new generation of sustainable tires to be manufactured by Michelin.

PlasticRecycling Resinprices Cellulosicfiber

-Black colorant, purging agent new at Techmer PM

Officials said the new purging agent reduces waste and enhances sustainability by saving energy and water and significantly reducing scrap and labor.

Techmer PM has come to market with a new black plastics colorant and a new purging agent. PlasticRecycling Resinprices Cellulosicfiber

The black colorant was developed because black plastic “causes endless headaches for plastics recyclers,” officials said, because typical carbon black pigments absorb the near-infrared (NIR) light used by recyclers to sort material streams. Officials said this process leads to tons of mixed plastics not being properly sorted, which means they can’t be recycled and end up in landfills.

“Whether it’s a body wash bottle or a dinner tray, it has to be sortable,” Steve Loney, market development director, said in an interview with Plastics News.

Techmer’s new, improved grades of NIR-sortable black colorant allows NIR reflection to enable accurate sorting at recycling facilities while maintaining the product’s black color.PlasticRecycling Resinprices Cellulosicfiber

By enabling verifiable recycling of black plastic, officials said the colorant allows brand owners who use carbon black in their products to better meet sustainability goals while maintaining their desired brand identity.