Polyester-Fiber – CO2 Emissions – Recycling 14-04-2022 - Arhive

Polyester-Fiber – CO2 Emissions – Recycling

-Replacement of Toxic Chemicals in the Manufacture of Tires and Conveyor Belts

The new adhesion promoters are based on natural raw materials

The quality of composite systems made of cords of high-strength fibers such as polyester, aramid or polyamide and matrix materials of rubber is largely determined by the adhesion properties of the fibers to the matrix. In the established manufacturing process, adhesion promoters made of resorcinol-formaldehyde-latex (RFL) are used to improve the adhesion properties. Researchers at DITF are showing ways to replace the harmful formaldehyde with technically equivalent substances that are harmless to health.

In car tires, conveyor belts and V-belts, as well as in many applications in the manufacture of technical products, rubber materials are reinforced by cord. High-strength fibers made of polyester, polyamide or aramid are used. They provide the necessary strength and rigidity of the overall composite and counteract external forces. As a result, deformation, elongation and torsion of the material can be kept low. Polyester-Fiber – CO2 Emissions – Recycling

However, these demands on the fiber composite material can only be met if there is sufficiently high adhesive strength between the fibers and the matrix (made of rubber or caoutchouc). Otherwise, delamination of the material composites, which are built up in alternating layers of fabric and rubber, is to be expected. Material failure would be the consequence.

Adhesion is increased by the use of adhesion promoters. Chemicals based on formaldehyde-resorcinol latex (RFL) have proven effective. They are applied to the fibers as so-called dips and ensure that their adhesion to the matrix of rubber is significantly improved. RFL is established as an adhesion promoter, but it has a significant drawback: since 2014, formaldehyde has been classified by the EU as demonstrably carcinogenic and mutagenic.

The chemical industry is therefore urgently searching for alternatives that are harmless to health. Polyester-Fiber – CO2 Emissions – Recycling

-Teijin Frontier Develops CO2 Emissions Calculator For Polyester Fiber

Teijin Frontier Co., Ltd., the Teijin Group’s fibers and products converting company, announced today that it has developed a proprietary system for calculating CO2 emissions generated by the company’s polyester fiber production processes. Going forward, Teijin Frontier eventually expects to use the system for full lifecycle assessments of its polyester fiber products. Polyester-Fiber – CO2 Emissions – Recycling

The new system calculates CO2 emissions based on data from the company’s manufacturing bases. It also compares differences in emissions between petroleum-derived fibers and recycled fibers to quantitatively evaluate the effect. The system additionally helps to clarify which processes need to be improved to further reduce environmental loads and better measures for reducing CO2 emissions can be considered.

Teijin Frontier has already begun using the system to evaluate emissions from polyester filaments and staple fibers production, and gradually will expand the scope to include weaved and dyed textiles products. The company also plans to encourage partners to adopt the system. Polyester-Fiber – CO2 Emissions – RecyclingTeijin Frontier, guided by its THINK ECO® environmental initiative, is striving to improve its environmental value, including through eco-friendly plant management and the development of greener materials and products for applications ranging from clothing to industrial materials. By implementing and further improving the newly CO2 emissions calculation system, the company expects to strengthen its contribution to the realization of circular economies.

-Robust Demand Comes Up Against Supply Roadblocks

The mood in spot resin trading last week was . . . boisterous. At the PlasticsExchange trading desk, the first full week of April was the busiest week in almost a full year, when the market was still reeling in the aftermath of the Houston winter storm. Demand from both processors and resellers remained strong as the second quarter began, but the general lack of prompt supply also continued.

Spot Prime resin prices saw little change this past week: Polyethylene (PE) held steady at 2022 highs, while polypropylene (PP) prices slid a cent from the season’s highs first established weeks ago, writes the PlasticsExchange in its Market Update.

Producers did secure their price increases in March. PE added $0.04/lb and PP followed monomer contracts up a solid dime. Polyester-Fiber – CO2 Emissions – Recycling

Producers are steadfast in keeping margins high, according to the PlasticsExchange, with another round of price increases nominated for April. Although upstream PE inventories are bulging at record levels, much of it is packed in warehouses and destined for export. With ongoing equipment and ocean freight constraints at hand, producers are keeping incremental export offers at bay or priced out of reasonable reach. Official US monthly resin production data has been delayed, but PE producers claim to have throttled back production significantly, which could create additional sourcing challenges.

PE trading and volumes rebounded as April fully commenced. Healthy demand and tight availability kept commodity-grade pricing stable at generally elevated levels. High-density (HD) PE took over as the primary mover in the PlasticsExchange marketplace, with relatively high volumes of Injection and Blow Molding grades changing hands, both domestic and export to Mexico and Europe. Low-density (LD) PE film grades also saw swift sales, with replacement material hard to find. Linear-low-density (LLD) PE Injection grades also moved well, and while there was demand for LDPE Injection, supplies were scarce and carried a hefty premium, limiting transactions. Polyester-Fiber – CO2 Emissions – Recycling

Despite the substantial movement of volume, export offers remained constrained at the beginning of April, a time when they might otherwise be plentiful, writes the PlasticsExchange. Producers secured their $0.04/lb March increase — the first uptick in contract pricing since July 2021. With limited export outlets because of logistics constraints, producers seem to have throttled back reactors to keep their surplus inventories from becoming overly burdensome. Perhaps the tight domestic availability and upward market momentum could propel PE prices even higher, as there is an additional $0.06/lb increase on average proposed for April.

-Knee-Jerk Plastic Ban Risks Accelerating CO2 Emissions

Plastic film ban for produce can increase environmental harm: every ton of food waste prevented by packaging saves 4.2 tons of carbon dioxide (CO2) equivalent.

In January, French Prime Minister Jean Castex set in motion a ban on plastic packaging for large numbers of fruits and vegetables.

The policy was applauded by those campaigning to reduce unnecessary plastic packaging, but few took the time to explore what repercussions this new law may have. Polyester-Fiber – CO2 Emissions – Recycling

In responding to consumers outcry to the waste and overuse of plastic packaging, President Emmanuel Macron ignored the fact that bans risk causing a serious increase in food waste due to reduced shelf life if plastic packaging is removed.

Also, this ban neglects supermarkets’ initiatives in creating loops for a range of awkward-to-recycle plastic packaging, such as films and bags. In fact, it seems to imply that all the efforts around educating consumers and setting up tailored sites to return packaging have failed.

The key issue here is that in attempting to reduce our use of plastic, we may end up causing more damage further along. And what makes a ban worse is that it can spread to other countries and regions. Polyester-Fiber – CO2 Emissions – Recycling

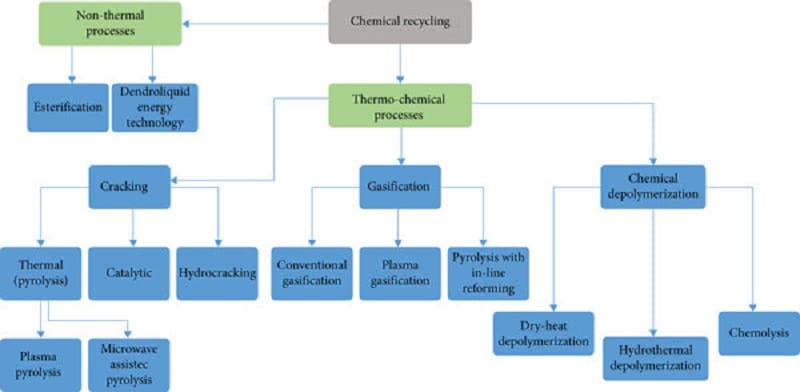

-The Potential of Chemical Recycling Technologies

Chemical recycling can help achieve the European targets on recycling plastics and contribute to the EU Green Deal ambitions on circularity and climate neutrality by 2050. To get higher recycling rates for plastic waste, complementary solutions need to be considered. Polyester-Fiber – CO2 Emissions – Recycling

Presently, there are three main routes for recycling of plastic waste: mechanical recycling, dissolution recycling, and chemical recycling. The latest has the potential to tackle mixed or contaminated plastic waste that cannot be recycled mechanically, which otherwise would be incinerated or sent to landfill, and to remove undesired additives and impurities. Chemical recycling can also eliminate the emissions linked to incineration and conventional production of feedstock materials.

According to Cefic’s updated position paper on Chemical Recycling, despite the use of chemically recycled plastics in multiple applications in Europe, the full implementation and integration of these technologies needs scaled-up innovations, investments, and a strong and enabling European policy framework.

Recently organised in March by ECP4, Agoria, Chemical Recycling Europe, EuPC, and Suschem, the Chemical Recycling Workshop, resulted in an overview of the potential of these technologies and challenges still faced by the industry in the path towards the scale-up of fully circular solutions. Polyester-Fiber – CO2 Emissions – Recycling

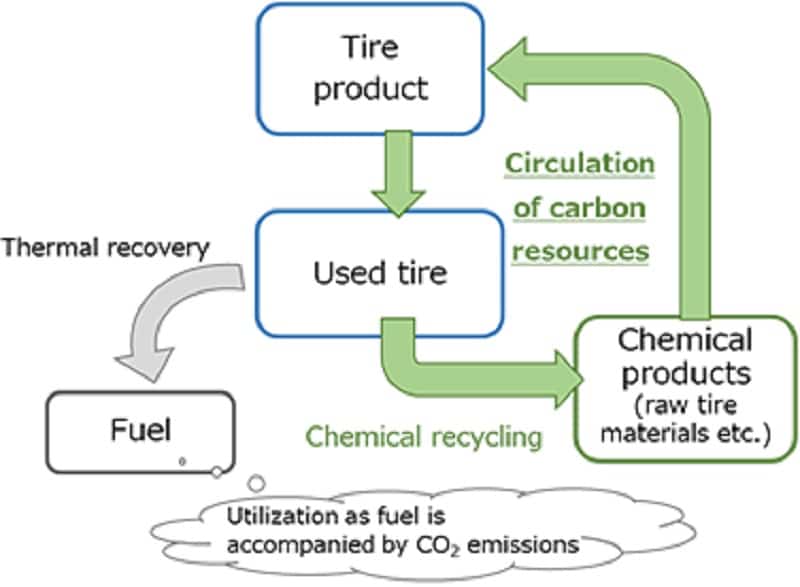

-Chemical recycling technologies of used tires

Work towards a low-carbon, recycling-oriented society

Research and development efforts to achieve carbon neutrality are accelerating around the world. Used plastics and rubber are utilized as fuel in Japan, mainly through thermal recovery, but this process consequently results in CO2 emission. Utilizing renewable resources is indispensable to the development of a low-carbon, recycling-oriented society. Polyester-Fiber – CO2 Emissions – Recycling

ENEOS Corporation is developing “chemical recycling technologies that enable precise pyrolysis of used tires” in collaboration with Bridgestone Corporation. Through this initiative, we aim to significantly reduce CO2 emissions and increase resource circulation .

Chemical recycling process

The demand for tires is expected to grow in the future alongside rising automobile and transportation demands. Synthetic rubber derived from petroleum is one of the primary materials used in tire production. Used tires are also utilized as fuel in Japan, mainly through thermal recovery . Polyester-Fiber – CO2 Emissions – Recycling

If the implementation of “chemical recycling technologies that enable precise pyrolysis of used tires” can be made into a reality, it should help contribute to reduced CO2 emissions and increased resource circulation.

Polyester-Fiber – CO2 Emissions – Recycling