Polyester Recycling Blue Hydrogen 22-10-2021 - Arhive

Polyester Recycling Blue Hydrogen

Crude Oil Prices Trend

LyondellBasell (NYSE: LYB) today announced it is now manufacturing polypropylene (PP) and polyethylene (PE) on a commercial scale with measurable and certified C14 renewable content from renewable feedstock. LyondellBasell’s newest product offering is differential in that it uses feedstocks that are not in competition with the food chain. The renewable feedstock is supplied by Neste and is produced 100 percent from bio-based waste and residues, such as used cooking oils. The LyondellBasell product also offers a lower carbon footprint compared with fossil-based polymers, is made in Europe and will be marketed globally under the name CirculenRenew.

“Our CirculenRenew product offering, with measurable and certified C14 renewable content, is game-changing in the market, as it is based on content made of waste and residue materials. This solution addresses the growing market needs for renewably sourced materials with a lower carbon footprint,” says Richard Roudeix, LyondellBasell Senior Vice President of Olefins and Polyolefins for Europe, Middle East, Africa and India. “Our CirculenRenew with measurable and certified C14 renewable content products have the same properties as their fossil-based equivalents and can be used for the same end-use applications.”

-Neste and Ravago plan to build a facility for chemical recycling

Neste and Ravago aim to establish a joint venture to build an industrial facility for chemical recycling in North Sea Port in Vlissingen, the Netherlands. The facility is intended to be the starting point of joint global chemical recycling (often also called “advanced recycling”) activities, built upon the advancement of the thermochemical liquefaction technology of US-based Alterra Energy, an innovative chemical recycling technology company.

With this, Neste, the world’s leading producer of renewable diesel, sustainable aviation fuel, and drop-in renewable feedstocks and solutions for the polymers & chemicals industry, and Ravago, the world’s leading distributor and recycler of polymers, plan to demonstrate and advance the commercialization of chemical recycling. The transaction is awaiting for and subject to regulatory approval.

Combining expertise along the value chain

This strategic partnership combines Ravago’s expertise in the mechanical preparation of plastic waste, Alterra Energy’s proprietary liquefaction technology, and Neste’s expertise in the processing of hydrocarbons. Polyester Recycling Blue Hydrogen

Neste and Ravago are aiming for the first industrial chemical recycling site in North Sea Port in Vlissingen with an annual processing capacity of about 55,000 tons of mixed plastic waste, corresponding to the plastic packaging waste generated by some 1.7 MM average EU citizens* per yr. The long-term aspiration of the partners is to significantly increase the processing capacity on a global scale and continuously develop the joint venture into a global leader for chemical recycling of mixed plastic waste.

OWPL consortium could deliver renewable power to produce green hydrogen on an industrial scale

Offshore Wind Power Limited (OWPL), the consortium formed by Macquarie’s Green Investment Group, TotalEnergies and Scottish developer Renewable Infrastructure Development Group (RIDG) has announced it is studying the use of offshore wind to power the production of green hydrogen on an industrial scale on the island of Flotta in Orkney, Scotland.

The OWPL consortium has submitted a proposal to the Crown Estate Scotland’s offshore wind leasing round (ScotWind) to develop the N1 plan option area west of Orkney. If successful, its proposal – called the West of Orkney Windfarm – could deliver renewable power to a green hydrogen production facility at the Flotta Terminal.

Plans to power the proposed Flotta Hydrogen Hub are being developed by OWPL in partnership with Flotta Terminal’s owner Repsol Sinopec, and Uniper, a leading international energy company and pioneer in the field of hydrogen. The proposal is also supported locally by EMEC Hydrogen who have spearheaded Orkney’s leading position in green hydrogen production.

Today, the U.S. Department of Commerce (the “Commerce Department”) announced its final determinations that imports of polyester textured yarn from Indonesia, Malaysia, Thailand, and Vietnam are being unfairly sold below their fair value in the United States.

In the final determinations announced today, the Commerce Department calculated antidumping duty (“AD”) cash deposit rates that ranged from 2.58 percent to over 56 percent. Polyester Recycling Blue Hydrogen

As a result of the final determinations, U.S. Customs and Border Protection will continue to collect antidumping duties in the amount equal to the final dumping cash deposits rates for imports from each producer or country (i.e., the “all others rate”). Importers will be required to post duty deposits at these AD rates on the date the final determinations are published in the Federal Register, in approximately one week.

-Thermoforming bioplastics – is that possible?

Bio-based plastics are suitable as packaging for food. But can these materials be processed on the machines available on the market and at the same production speeds?

In the field of rigid packaging, the production of rigid packaging, the technology of thermoforming plastics is a widely used manufacturing process. Most thermoformed packaging worldwide is still formed from polypropylene (PP), polyethylene terephthalate (PET) and polystyrene (PS). Polyester Recycling Blue Hydrogen

Bioplastics, biodegradable and bio-based, still play an outsider role here. Due to their low availability of raw materials and legal requirements, these are only used in certain applications. Measured against the total annual plastic production (2019) of 368 million tonnes, bioplastics account for only about 1% [1]. From a technical point of view, however, there is nothing to be said against the increased use of these materials in thermoforming. Depending on the product design, the format design of the tool, the machine type and the plastic used, quantities of individual thermoforming systems of up to 150,000 parts per hour are common.

Technically sustainable solutions

With the guiding principle “Circular Thinking”, Illig Maschinenbau develops solutions for packaging manufacturers and thus supports the economic circular concept. The sustainability goals are clearly defined: reduce, reuse, separate, recycle and renew.

-Double-Digit Price Hikes on China Exports Add to Inflation Risk

- Higher input costs and strong demand prompt price increases

- While everywhere, China goods a small part of consumer outlays

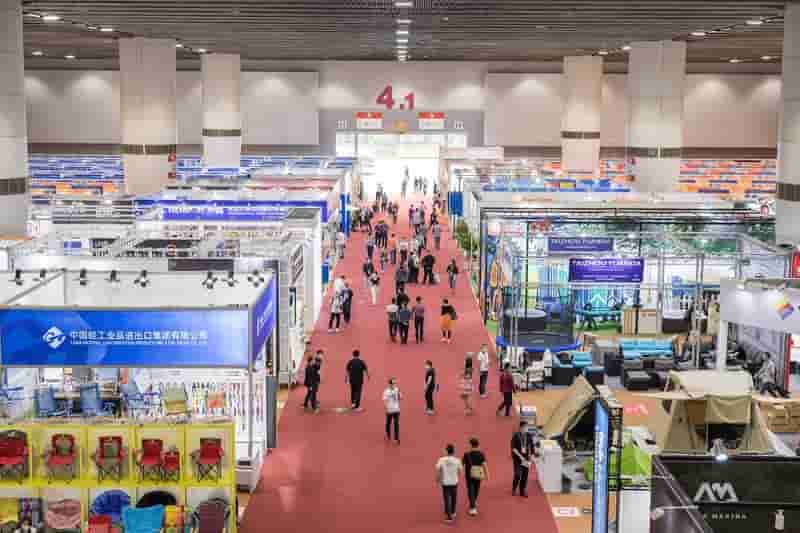

Business is booming for Zhejiang Zhendong Leisure Products, which churns out about 1 million folding chairs a year from its factory in eastern China, many of which end up on American porches and gardens across Europe.

A spike in demand since the pandemic has led to a backlog of orders lasting until next April and has given the company enough confidence to raise prices by 10%. Rather than hurting demand, “buyers are placing more orders now for fear that prices might rise further in the future,” overseas sales manager Sonia Lu explained from her booth at the Canton Trade Fair in the southern city of Guangzhou.

Those who want a parasol next to their outdoor recliner face an even steeper increase. Shaoxing Gaobu Tourism Products Co. Ltd., which makes beach and garden beach umbrellas sold through retailers like Walmart Inc. and Carrefour SA, has raised prices about 20% and isn’t worried about losing orders either.

“Whichever sellers our customers go to, the reality they’ll have to face is the same: price increases,” said sales person Lyric Lian.

That was the consistent refrain from exporters at the world’s biggest trade fair, where China’s strict quarantine rules restricted foreign buyers to only a handful last week compared with the thousands during pre-pandemic days.

-3M to pay $99 mn to settle dispute over harmful chemicals

The US group 3M, which among other things manufactures anti-Covid protective face masks, said Tuesday it will pay $99 million to settle complaints related to health and the environment. Polyester Recycling Blue Hydrogen

“3M has reached a collaborative agreement to resolve ongoing litigation and negotiations related to per- and polyfluoroalkyl substances (PFAS) near 3M’s Decatur, Alabama facility,” the company said in a statement.

Lawsuits had been filed against 3M in three US states – Alabama, Illinois and Minnesota – as well as in Germany and Belgium, charging that its products contain potentially harmful chemicals known as PFAS which are present in wide variety of products such as Teflon, paints, packaging or textiles.

The agreement was signed with the city of Decatur, Morgan County, plaintiffs from Saint John, and the Tennessee Riverkeeper organization, said the manufacturer of post-it notes, adhesive tape and Covid face masks.

“Through these agreements, subject to final approval, 3M will support activities to address PFAS that 3M manufactured or disposed of, as well as to enhance the quality of life for Decatur residents,” the group said.

-A Case for European Blue Hydrogen

H2 hydrogen ebook

In August this year the paper ““How green is blue hydrogen?” hit the academic press. Co-authored by Professor Howarth of Cornell University, the paper makes the case that reforming natural gas alongside carbon capture and storage (CCS) to produce blue hydrogen can generate more than 20% more greenhouse gas (GHG) emissions than the direct use of natural gas.

This conclusion follows an analysis of two blue hydrogen plants, one in the US and one in Canada, and, importantly, is based on two key assumptions: fugitive methane emissions from natural gas production are set at 3.5% following analysis of US leakage statistics, and the power supply for the CCS process is supplied from gas-fired generation. In addition, the two plants reviewed utilise steam methane reforming (SMR) technology, which is less efficient and has a lower carbon capture rates than autothermal reforming (ATR).

The need for caution in taking the Howarth paper at face value was highlighted within weeks of publication, as noted by the SINTEF blog article Assumptions Matter When Assessing Blue & Green Hydrogen.

Energy academics from the University of Cork, Ireland, the University of Sheffield, UK, Imperial College London, UK, the Oxford Institute of Energy Studies (OIES) and key hydrogen market participants also confirmed the need for caution to ICIS, highlighting the importance of the assumptions underpinning the Howarth paper.

-Sustainable and responsible innovation focus for FIMAST

Responsible innovation, sustainable technology and new opportunities in emerging markets highlighted at hosiery sector show.

Manufacturers of yarns, hosiery, machinery, components and accessories – the hosiery supply chain met yesterday in Brescia for the opening of FIMAST, the Italian Exhibition Group’s (IEG) B2B event being staged at Brixia Forum until Friday, 22 October. Exhibitors and visitors from Germany, Spain and Portugal were also in attendance for an event showcasing the latest innovations for the hosiery industry, a sector whose companies are mainly located in the Italian manufacturing Italian districts of Brescia and Mantua.

The four days of FIMAST will offer moments of debate on the sector’s scenarios, outlined by international experts in a qualified panel of events – an opportunity to reflect on innovation, research, new business opportunities, emerging markets and sustainability, a central element for the sector’s development. Polyester Recycling Blue Hydrogen

-LG Chem develops substance for creating cheaper, lighter plastic solar panel frames

LG Chem combined polycarbonate and acrylonitrile styrene acrylate (ASA) to develop LUPOY EU5201 to be used in plastic frames for solar panels.

Consequently, LG has become the first in South Korea to develop plastic solar panels frames.

LUPOY EU5201 is a high-performance engineering plastic material infused with fiberglass in a polycarbonate compound to boost durability and structural integrity through diverse temperature ranges.

The plastic frames, which account for 10 percent of the solar panel, could drastically reduce production cost and the weight of solar panels that could simplify transportation and installation.

The substance has similar durability to aluminum, the common material used for solar panel frames, but is half the weight and is price competitive.

In addition, the material can endure diverse temperatures while maintaining its original form with enhanced safety.

LG Chem officially started to sell the frames beginning this month.

Polyester Recycling Blue Hydrogen