Polymers Petrochemicals Recycled PET 26-02-2019 - Arhive

A decade after the crash, many nations are still on emergency monetary policies, even before a new downturn strikes

President Xi, left, and President Trump at a trade meeting in December.

Central banks are getting twitchy. On average, recessions have come along once a decade since the mid-1970s and the nadir of the last downturn occurred almost a decade ago.

The Nobel prize-winning economist Paul Krugman has predicted that there will be a recession in America by the time Donald Trump comes up for re-election at the end of next year.

- China – Polyethylene Terephthalate

PET and its chain continue to be weak.

- Polyamide6 and its chain are tendencely better than yesterday.

PET Bottle grade export 1,030/1,075 $/ton – PET Bottle grade domestic market 8,200/8,300 yuan/ton – PET Filament grade SD domestic market 7,600/7,750 yuan/ton – PET Filament grade BR domestic market 7,600/7,750 yuan/ton

PTA Taiwan 850/860 $/ton – PTA domestic market 6,300/6,400 yuan/ton – MEG $ 610/620 $/ton – MEG domestic market 4,950/5,050 yuan/ton – PX Korea 1,090/1,105 $/ton

POY 150D/48F domestic market 8,200/8,350 yuan/ton – DTY 150D/48F domestic market 10,250/10,350 yuan/ton – PSF domestic market 8,700/8,850 yuan/ton

The contract price of para-xylene in Asia for March deliveries was nominated at USD1,190-1,200 per tonne, market sources told ICIS on Tuesday.

For example, South Korean S-Oil, SK Global Chemical and Japanese JXTG Nippon Oil & energy announced their March contract prices for material at USD1,200 per tonne, CFR Asia.

Meanwhile, ExxonMobil announced its March contract price for para-xylene at USD1,190 per ton, CFR Asia.

The February contract price of paraxylene in the region was set at USD1,050 per tonne, CFR Asia.

Crude Oil Prices Trend

Materials Resin Pricing Materials Suppliers

The year got off to a bit of a rough start for North American polypropylene, solid polystyrene and PET bottle resin markets.

Regional PP and solid PS prices both fell an average of 2 cents per pound in January, with PET down 1 cent, according to market sources contacted by Plastics News. Prices for PP continued a slide that has seen them tumble a total of 18 cents in November and December.

Like previous price drops, the January PP slide was tied into lower prices for polymer-grade propylene feedstock. Those prices have dropped as propylene supplies have increased. North America now has the lowest PGP prices in the world, according to Scott Newell, a market analyst with Resin Technology Inc. in Fort Worth, Texas.

Lithuanian PET stretch-blow moulding machinery maker, FlexBlow, is building a new 3,500sqm facility in addition to its existing 10,000sqm site in Kretinga, as the company expands capacity and improves its technology.

Since its formation in 1994, the family-owned company has witnessed the development of the PET bottle blowing business, with shrinking production batches and increasing demand for greater in-house PET container production flexibility.

The vision for FlexBlow’s new site, which is expected to open in July 2019, is set to transform the company’s processes and operations by introducing a complete manufacturing environment that operates based on real-time data collection and localisation during production. The installation includes intelligent robot units, a dedicated testing laboratory, and 3D printers for both plastics and metal components.

Roger Renstrom, Plastics NewsJeff Hrivnak, Solvay Specialty Polymers global healthcare business manager, discussed material substitution issues in a Center Stage presentation at the UBM Advanced Manufacturing expo in Anaheim, Calif.

Anaheim, Calif. — Jeff Hrivnak made a rational case on utilizing specialty polymers instead of metal in a presentation at the UBM Advanced Manufacturing expo in Anaheim.

In discussing material substitution issues, he outlined the benefits of polymers including a material’s performance and the total cost of ownership.

Hrivnak is global business manager for health care at Solvay’s Specialty Polymers business unit in Alpharetta, Ga.

Total SA Acquisition increases company’s PS capacity by 400ktpa

Ineos Styrolution has completed the previously-announced acquisition of two polystyrene production sites in China from French energy giant Total SA.

The acquisition includes the purchase of Total’s wholly owned Chinese PS business, which comprises two production sites in Ningbo and Foshan and two related offices in Guangzhou and Shanghai.

Driven by the company’s “triple shift” strategy, the transaction signals Ineos Styrolution’s first production move into China and will increase the company’s PS capacity by 400 kilotonnes per annum.

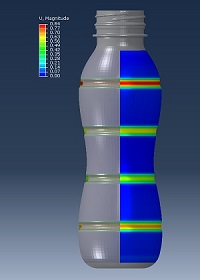

Although computer-generated simulation has been used for many years to evaluate the structural attributes of a bottle before it is even blown, oftentimes the process stops short.

PTI shrink-sleeve simulationIf you consider that labels are the “hook” by which consumers are enticed to purchase the particular product, it stands to reason that simulation should be expanded to include what happens to the visual attributes once the label is applied to a bottle.

Even though your internal designers or external design house are capable of creating a stunning label, have you given any thought to how what happens to the visual impact should those graphics end up distorted?

By autumn 2019, BBC Cellpack Packaging will expand its production site in Illfurth, France, with state-of-the-art ultrasonic technology for the manufacture of resealable stand-up pouches for baby food, beverages and cosmetics. BBC Cellpack Packaging is the first company in the field of flexible packaging solutions to realize the entire manufacturing process for stand-up pouches using ultrasonic. By using this technology, BBC Cellpack Packaging will completely convert production to recyclable monomaterials and significantly reduce carbon emissions.

The trend is towards disposable convenience packaging. Individually portioned, resealable, hygienic, light and flexible.

Biome Bioplastics and Futamura have partnered to demonstrate a range of bio-based and compostable multilayer films.

The materials offer competitive performance, while tackling the negative environmental impact of traditional oil-based, non-recyclable multilayer packaging.

Sustainable alternatives to challenging packaging formats such as multilayer pouches will be key to meeting the UK Plastics Pact target that 70 per cent of plastic packaging is effectively recycled or composted by 2025.

The extension of a 90-day trucein the trade dispute between the US and Chinashould boost optimism in the Asiancountry and remove some of the gloomsurrounding its outlook.

Had the deadlinetranspired, the US would have imposed a 25%tariff on $200bn worth of Chinese imports, upfrom the 10% tariff it imposed on the samegoods in September.

China would have likely retaliated, since ithad done so for each of the other tariffs thatthe US had imposed on imports from thatcountry.

President Donald Trump saidhe was extending the 1 March deadlinebecause of progress the US was making in itstalks with China.

He did not specify a new deadline for thetariffs.

His statement caused a jolt in optimism inChina, fuelling a 5.60% rise in the compositeindex of the Shanghai Stock Exchange.

The US is set to impose “even stronger sanctions” on Venezuela President Nicolas Maduro’s financial networks, likely further hindering crude oil production and exports as US sanctions on state-owned oil company PDVSA entered their fifth week, US Vice President Mike Pence said Monday.

“We will find every last dollar they have stolen and return that money to the Venezuelan people,” Pence said in a speech in Colombia before the Lima Group. “As we continue to bring economic and diplomatic pressure to bear on the Maduro regime, we hope for a peaceful transition to democracy, but as President Trump has made clear, all options are on the table.”

The European Union (EU) and others—including policy makers, companies, and organizations—have recently announced goals to reduce or eliminate the amount of plastic packaging sent to landfills. For example, Kraft Heinz announced in July 2018 that it aims to make 100 percent of its packaging globally recyclable, reusable, or compostable by 2025.

A few months earlier, the American Chemical Council’s Plastics Division announced targets of 100 percent of plastic packaging being recyclable or recoverable by 2030 and 100 percent of plastic packaging being reused, recycled, or recovered by 2040. As early as February 2016, the Plastics Trade Association launched the Zero Net Waste program, which recognizes plastics companies that take steps to reduce net waste in manufacturing. These goals fit in well with the drive toward the “circular economy” idea that is being pushed by the EU as a way of meeting the dual objective of minimizing waste and reducing the use of raw materials and energy.