Recycled PET – Low-carbon-H2 21- 02-2023 - Arhive

Recycled PET – Low-carbon-H2

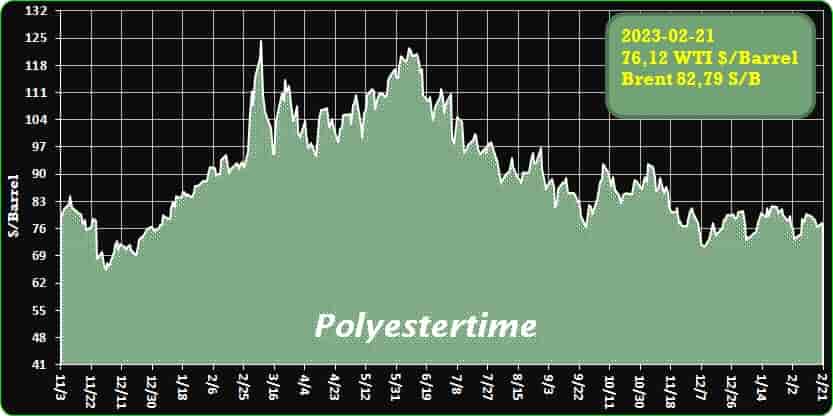

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Sulzer acquires stake in Fuenix Ecogy and completes portfolio for plastic waste reduction

Sulzer has signed an agreement with circular technology company Fuenix Ecogy to acquire a strategic stake in its plastic upcycling business.

The partnership will drive the development, commercialization and adoption of advanced, fully integrated solutions for plastic waste processing. The move will allow Sulzer to offer complete recycling lines based on Fuenix’s Ecogy® technology and Sulzer’s own proven separation and purification solutions. Sulzer Chemtech is an established licensor of reaction and separation technologies aimed at driving the chemical recycling of materials.

Fuenix Ecogy® technology converts sorted end-of-life mixed plastic waste into high-value hydrocarbons with virgin-like properties. The solution offers high recovery and conversion rates, enabling a high degree of circularity in the plastic value chain.

With this strategic investment, Sulzer is sharing its leading technical expertise to support the scale up and commercialization of a cutting-edge pyrolysis technology. The agreement also expands Sulzer Chemtech’s technology licensing portfolio for polymer processing, in line with its overarching mission to help industry adopt more sustainable practices.

As the exclusive licensor of the technology, Sulzer Chemtech will be able to offer complete as well as partial recycling lines based on Fuenix’s Ecogy® pyrolysis technology and its own proven separation and purification solutions. At the same time, Sulzer Chemtech will continue to offer its separation and purification know-how and solutions to other plastic recycling technologies.

– Selects France as New Location to Manufacture Recycled PET Plastics

February 16, 2023 – TheNewswire – Loop Industries , a clean technology company whose mission is to accelerate a circular plastics economy, has chosen the Chemesis industrial platform in France as the location for it’s new manufacturing facility to produce 100% recycled polyethylene terephthalate plastic and polyester fiber.

The company says that the new facility will help meet growing demand for recycled polyethylene terephthalate plastic. Recycled PET – Low-carbon-H2

The facility has a planned capacity of 70,000 metric tons per year and will save over 255,000 tonnes of CO2 annually, while also contributing to the sustainable revitalization of the local industrial base.

Loop expects to commence construction in 2025, with plant commissioning slated for 2027. The company says that the project will provide a sustainable solution to the global plastic waste challenge by leveraging low-value waste and utilizing Loop’s depolymerization technology.

-Solvay signs MoU with Cyclic Materials

Solvay has signed a memorandum of understanding (MoU) with Canadian start-up Cyclic Materials to develop a supply chain for recycled rare earth permanent magnets, said the company.

Under the agreement, the partnership will develop the production and supply of recycled mixed rare earth oxides which will be sent from Cyclic Materials’ site in Ontario, Canada to Solvay’s plant in La Rochelle, France.

Cyclic Materials recycles rare earth permanent magnets to produce raw materials for applications in the automotive, wind energy and electronics industries and is working to build domestic supply chains across Europe and North America.

Solvay has been working with Cyclic Materials to validate product compatibility with its rare earth separation process. Recycled PET – Low-carbon-H2

“Cyclic Materials will provide us key raw materials for our plant to successfully produce rare earths for magnet manufacture, electronics and catalysts,” said Ilham Kadri, Solvay CEO. “As the European Commission finalises the European Critical Raw Materials Act, supplies of recycled materials are becoming critical to European manufacturers. This MoU prepares us for a future offtake agreement which will further our efforts to provide certifiably recycled materials to these markets.”

The agreement will help Solvay to implement the development of a major hub for rare earth magnets in Europe. Last year, the Belgian-headquartered firm announced plans to expand rate earth operations at its La Rochelle site. Recycled PET – Low-carbon-H2

-Freudenberg Performance Materials Launches Evolon ESD

Packaging textile prevents electrostatic discharge and protects sensitive surfaces from damage

Freudenberg Performance Materials is widening its product range of technical packaging textiles. Evolon ESD protects automotive and industrial parts with electronic components from electrostatic discharge. This includes trim lines, dashboards, mirrors, steering wheels, etc. In addition, Evolon ESD prevents scratching of very sensitive surfaces. The new technical packaging textile also provides several sustainability benefits: it helps manufacturers to reduce their scrap waste, it is long-lasting, and is made from recycled polyester.

The ESD (ElectroStatic Discharge) feature of the new Evolon technical packing textile provides permanent electrostatic discharging protection and the fabric’s surface resistivity can be customized. Recycled PET – Low-carbon-H2

This eliminates ESD damage to electronic components during transport because electrostatic charging due to movement and friction is safely prevented. As this kind of damage cannot be detected with the naked eye, Evolon ESD helps to avoid failures which can occur after the final product is assembled and released. Manufacturers benefit from fewer complaints and warranty costs, as well as better end customer satisfaction.

Unlike conventional ESD packaging solutions, Evolon ESD also protects parts surfaces by avoiding micro-scratches or lint contamination. By using Evolon reusable packaging to transport parts with highly-sensitive surfaces, customers reduce the number of damaged parts and the reject rate. Recycled PET – Low-carbon-H2

Evolon microfilament textiles are also extremely strong and are available in different weights to meet a wide range of requirements – from lightweight to heavy-duty. They can be used to pack and transport very heavy parts without damage. In addition, Evolon fabrics are extremely durable, and contain up to 85% recycled PET.

-PET recycler Circularix to open second Florida plant

On the heels of opening the company’s first PET recycling facility in Pennsylvania, Circularix LLC expects a second site to begin operations in just a matter of months.

Three more will be coming in rapid succession after that.

Circularix Chief Operating Officer Alex Delnik is now revealing the second site is in Ocala, Fla., where the company already has a building, ordered recycling equipment and is awaiting delivery. Recycled PET – Low-carbon-H2

“Our second plant is going to be in Florida, actually not far from here,” Delnik said at the recent Packaging Conference in Fernandina Beach, near Jacksonville. “And it’s expected to start production probably late summer. It’s going to be followed by plants with a frequency of about five to six months. So we expect our roll-out to be completed by the end of 2024, maybe early 2025, that we’ll have the full capacity.”

Circularix plans to build an initial network of five recycled PET flake-to-pellet reprocessing facilities around the country. Delnik said other locations will be in the Pacific Northwest, the West Coast and Texas. Recycled PET – Low-carbon-H2

Full capacity for the five plants will amount to the production of 275 million pounds of food-grade recycled PET pellets annually.

-Diversification to other markets in 2023 crucial for PP producers because of China risks

THE GLOBAL polypropylene (PP) business is waiting with bated breath for the release of the January-February trade in late March. Since 2020, China has released the January-February data together.

So, we must wait until nearly the end of the first quarter to get an early steer on the strength of China’s imports and exports in 2023. This is just one example of an increasingly opaque Chinese market. Recycled PET – Low-carbon-H2

When the trade data has been released, we can add the ICIS estimates for local production in January-February to get an initial idea about how demand is shaping up for 2023 (demand equals net imports plus local production minus some end of year adjustment for over- or understocking).

We’ll still likely be very much in the dark, however, over this year’s China PP trade flows and demand. The reason is the impossibility of measuring the strength of consumer and investor sentiment now that the zero-COVID policies have been abandoned.

Nobody knows the degree of confidence in government policies, and how this will shape spending and investment, following the sudden decision to abandon zero-COVID in November last year. Recycled PET – Low-carbon-H2

And however sensitive this issue is to address it must be addressed. A 16 February New York Times article suggests that rough estimates indicate between 1m-1.5m people could have died since the zero-COVID restrictions were removed, much higher than the official numbers. How will this debate effect confidence in the economy?

-ExxonMobil chooses “industry-leading” technology for world’s largest low carbon hydrogen facililty

Topsoe, a global leader in carbon emission reduction technologies, has agreed to deliver its industry-leading hydrogen SynCOR™ technology to ExxonMobil’s planned low carbon hydrogen production facility in Baytown, Texas. The plant is expected to be the largest low carbon hydrogen facility in the world. Recycled PET – Low-carbon-H2

ExxonMobil’s low-carbon hydrogen, ammonia, and carbon capture facility is expected to generate up to 1 billion ft3 of hydrogen per day, delivering low-carbon fuel to the Baytown olefins plant and other Houston-area facilities. Replacing natural gas with hydrogen at the Baytown olefins plant could reduce the integrated complex’s CO2 emissions by up to 30%.

Elena Scaltritti, CEO of Topsoe, said, “We are very excited to support ExxonMobil with our unique technology. Recycled PET – Low-carbon-H2

Once complete, this ambitious project will result in hydrogen that can be used for low-carbon fuels and chemicals to help meet global net zero targets.”

Dan Ammann, President of ExxonMobil Low Carbon Solutions, said, “The scale of this project is expected to enable up to a 30% reduction in Scope 1 and 2 emissions from our Baytown facility by switching from natural gas as a fuel source to low-carbon hydrogen.”

Recycled PET – Low-carbon-H2