Smart textile – Toyota is working on a truly sustainable battery chain 13-12-2023

“Plastic that makes the difference”

Smart textile

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Cyclyx to build its first plastic feedstock production facility

The Cyclyx Circularity Centre will have a capacity to produce around 136,000 tonnes of plastic feedstock for chemical and mechanical recycling, with ExxonMobil and LyondellBasell holding offtake rights

Cyclyx International, a joint venture between Agilyx, ExxonMobil, and more recently LyondellBasell, has made the final investment decision to build its first Cyclyx Circularity Centre (CCC) in Houston, United States. Smart textile

The facility will have a capacity to produce around 136,000 tonnes (300 million pounds) of plastic feedstock for chemical and mechanical recycling, with ExxonMobil and LyondellBasell holding offtake rights. Together, the two companies are investing $135 million into Cyclyx to fund operating activities and construction costs for the new facility, which is expected to start operations in mid-2025.

Cyclyx draws on a database of over 1500 post-use plastic chemical characterisations to assesses each source of waste plastic to understand its chemical profile. It then uses artificial intelligence and big data to sort those profiles into the various mechanical and chemical recycling pathways that the plastics can be used for. Smart textile

The CCC will focus on sorting and custom blending collected material to ensure feedstock specifications and classifications meet expectations for ExxonMobil and LyondellBasell.

Toyota is working on a truly sustainable battery chain

Toyota is actively advancing its commitment to sustainable battery practices through a strategic collaboration with Cirba Solutions in the United States. The agreement focuses on the recycling of electric car batteries, a crucial step in Toyota’s efforts to create a truly sustainable battery chain. In the Lancaster plant in Ohio, batteries from Toyota’s vehicles, including the widely distributed Prius and other electrified cars, undergo a meticulous dismantling process by Cirba Solutions, achieving an impressive 95% material recovery rate. Smart textile

While Toyota may have entered the zero-emission vehicle market later than some competitors, it has a significant presence with over 6.2 million hybrid vehicles sold in North America. The collaboration with Cirba holds particular significance as it addresses the need to recycle batteries from Toyota’s existing fleet. Annually, approximately 25,000 batteries from end-of-life vehicles are collected by Toyota’s dealer network, emphasizing the importance of establishing sustainable practices.

Toyota’s partnership with Cirba aligns with its broader commitment to battery recycling, complementing existing agreements, such as the one with Redwood Materials on the West Coast. Christopher Yang, Vice President of Toyota Motor North America, underscores the significance of this collaboration, stating that Cirba Solutions’ network enhances Toyota’s ability to collect and recover batteries nationwide, contributing to cost reduction and a lowered operational carbon footprint.

The ultimate aim is to establish a closed-loop ecosystem, ensuring sustainability across the entire battery life cycle. Smart textile

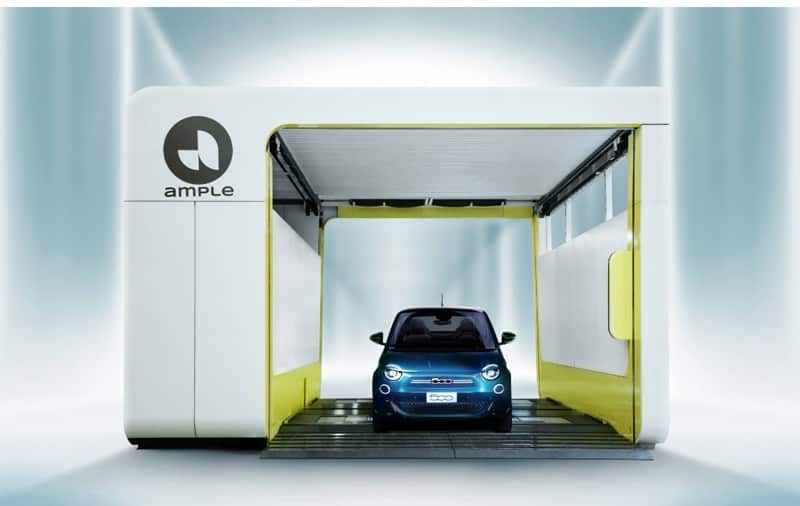

Stellantis tests electric car battery swapping

Stellantis and Ample have recently solidified a strategic partnership through a binding agreement, signaling a significant step in the realm of electric vehicle (EV) technology. The collaboration is centered around Ample’s Modular Battery Swapping solution, a groundbreaking battery swapping technology that enables Stellantis electric vehicle owners to replace depleted batteries with fully charged ones within minutes at dedicated swapping stations. Smart textile

This innovative approach deviates from traditional recharging methods, promising a rapid turnaround of less than five minutes for a fully charged battery. Stellantis, the automotive giant, and Ample are not only committing to the integration of this technology into electric vehicles but are also contemplating its expansion to cater to the broader needs of the Stellantis fleet. Geographical diversity is also on the agenda, extending beyond Europe.

The pilot program, scheduled for a 2024 launch in Madrid, Spain, will initially involve 100 FIAT 500e vehicles, a flagship model for Stellantis in the electric vehicle market. This initiative aligns with the Free2move car-sharing service offered by Stellantis. Ricardo Stamatti, Senior Vice President of the Charging & Energy Business Unit at Stellantis, expressed enthusiasm about the partnership, emphasizing the exploration of solutions that facilitate mobility freedom for electric vehicle customers.

Khaled Hassounah, CEO of Ample, proudly highlighted the commitment to making electric vehicles universally accessible without compromises to make a substantial impact on emission reduction. Smart textile

Germany in provisional exercise, the Scholz government is in chaos over the budget and the economy is doing badly

In the midst of a provisional exercise, Germany finds itself ensnared in a tumultuous scenario under Chancellor Olaf Scholz’s leadership. Promising no cuts to the welfare state amidst plummeting poll numbers, over half of Germans contemplate early elections alongside European ones, as the current legislature, scheduled until autumn 2025, navigates a deep crisis, particularly with the budget. Smart textile

Historically, Germany’s budget prowess, a stronghold during the Merkel era, now teeters, turning Berlin into the subject of European mockery. The Constitutional Court’s rejection of a 60-billion-euro expedient in November escalated the chaos, revealing 29 special vehicles with 869 billion against the Charter, leading to a freeze on spending by Finance Minister Christian Lindner, except for defense and parliament.

The looming specter of starting 2024 in provisional operation, where only essential expenses are permitted, underscores the critical impasse. With 17 billion yet to be covered, the “traffic light” majority, comprising the Social Democratic Party, the Greens, and the Liberals, grapples to reach a consensus on where to make cuts.

As the economic indicators reflect a dire situation—with manufacturing PMI below 50 points for over a year and a half and negative GDP growth—the political disarray is exacerbated by the rising popularity of the AfD, a conservative right-wing party accused of being “neo-Nazi.” Smart textile

The potential influence of the AfD adds a layer of complexity to an already precarious political landscape, raising questions about the endurance of Germany’s established order. The nation, once an economic and political stalwart, now grapples with uncertainties that reverberate beyond its borders.

Puma expands fibre-to-fibre recycling

Puma is intensifying its commitment to sustainable practices by expanding its Re:Fibre polyester recycling technology. The sports brand aims to derive 100% of its polyester from textile waste, shifting away from PET fibers sourced from bottles. Starting in 2024, the majority of Puma’s replica football jerseys will feature fibers crafted from old garments and factory waste instead of recycled PET bottles. Smart textile

The Re:Fibre pilot, initiated in 2022, has already been employed to produce replica kits for the Women’s World Cup and Girona’s 2023/24 season third kit. In 2024, the official Puma football replica jerseys, including those for the Euro and Copa América tournaments, will adopt the Re:Fibre technology. The program involves collecting, sorting, and processing textile waste through a chemical recycling process, ultimately producing new Re:Fibre fabrics.

Anne-Laure Descours, Chief Sourcing Officer at Puma, emphasizes the brand’s ambition for a complete transition to polyester sourced from textile waste, addressing the environmental risk posed by textile waste accumulation in landfills. Puma recognizes the need to rethink production methods, embracing a circular business model as a key element of its sustainability strategy. Smart textile

To make the technical process more accessible, Puma has employed computer-generated imagery in an explanatory video showcasing the Re:Fibre journey, from waste collection to molecular chemistry. This effort aligns with Puma’s response to research revealing that 71% of young people desire brands to make stronger environmental commitments, communicate goals more effectively, and enhance transparency.

Smart textile fiber places conductivity and flexibility side-by-side

Electrically conductive “smart fabrics” have many potential applications, but their specialized fibers typically aren’t as soft and flexible as those made of regular materials. An experimental new two-faced fiber, however, is both flexible and conductive.

Developed by a team of scientists at Washington State University, the fiber is made of two substances: cotton cellulose obtained from recycled T-shirts, and an existing conductive synthetic polymer known as polyaniline. Smart textile

The polyaniline is combined with the cotton cellulose because it’s too brittle to be formed into usable fibers on its own. That said, the two materials aren’t simply blended into one homogenous mixture. If they were, the polyaniline would be diluted to the point that it would lose its conductivity.

Instead, liquid solutions of the two substances are extruded from two separate (but closely spaced) nozzles, merging and bonding to form a single fiber which is cotton cellulose on one side and polyaniline on the other. Smart textile

In lab tests, such fibers have exhibited excellent electrical conductivity while also offering the strength and flexibility of cotton. They have also been successfully used in textile systems that delivered power to an LED light, and that sensed ammonia gas.

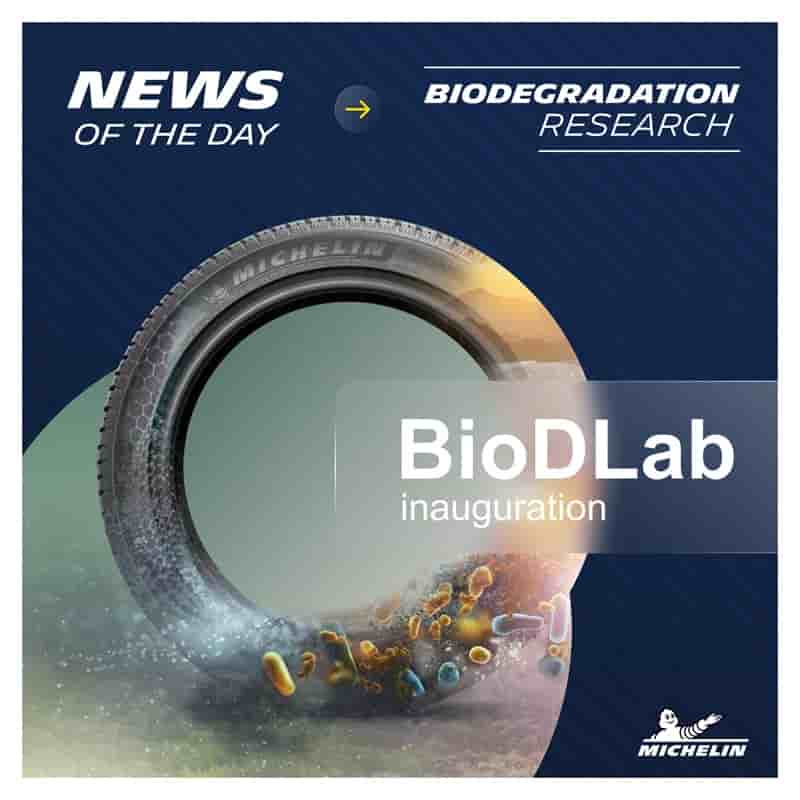

The objective is to comprehend the processes of degradation and biodegradation for the purpose of devising technical solutions to environmental challenges

Michelin, the renowned French tire manufacturer, joined forces with Clermont Auvergne University and the Center National de la Recherche Scientifique (CNRS) to delve into the wear degradation of tires. This involves the consequential formation of microparticles and the subsequent study of the biodegradation mechanisms associated with these microparticles. Smart textile

Establishing the BioDLab, a dedicated laboratory, is a pivotal step in this collaborative venture. The primary mission of BioDLab is to scrutinize the underlying causes of tire wear degradation and develop technical interventions for environmental predicaments. One of the focal points is exploring methods to render wear particles biodegradable in the environment.

Tire erosion, an inevitable consequence of contact with road surfaces, is essential for ensuring vehicle safety and traction. Tires, alongside fabrics, are identified as primary contributors to the creation and dissemination of microplastics in the environment, with rubber being the specific material of concern. Smart textile

Over the span of four years, the project will systematically investigate the chemical phenomena associated with microparticle degradation under the influence of solar energy and water. This interdisciplinary approach combines material science, chemistry, and microbiology to unravel the intricate regulatory mechanisms of this process.

The research specifically targets the degradation of rubber used in tires, employing photochemical and thermochemical processes, as well as exploring biodegradation facilitated by microorganisms and enzymes. Approximately twenty researchers from the Clermont-Ferrand Chemistry Institute (University of Clermont Auvergne/CNRS) and ten technicians from Michelin’s Operational Research and Development Department will be actively engaged in this collaborative effort.

Michelin’s ongoing commitment to reducing tire abrasion has resulted in a 5% decrease in microparticle emissions from wear between 2015 and 2020, a testament to their expertise in materials science. Smart textile

Smart textile