The fibers are derived by breaking down fibers from plant materials, such as wood, by treating them using machines and chemicals into finer fibers measuring nanometers in diameter. They weigh just one-fifth as much as steel but are three to five times stronger. The fibers are expected to have many industrial applications, including as a material in auto bodies.Asahi Kasei plant-derived nanofibers

Because it is derived from plants, CNF is more environmentally friendly than carbon fibers, which are derived from petroleum and manufactured by baking acrylic fibers.

Another merit to CNF is that it can be made from various types of plants, a major advantage for Japan because of its lack of natural resources.

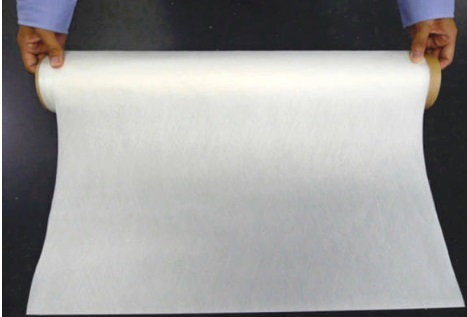

The lab where Asahi Kasei plans to conduct trial production is a facility it uses for research and manufacturing of a wide variety of products, including fibers and electronic components. Sheets of nonwoven fabrics made of CNF will be manufactured there.

The fabrics are a porous material made of fibers measuring, on average, 100 nanometers or less in diameter. One nanometer is equal to one-billionth of a meter. The company envisions them being used in heat-exchange membranes for air conditioners and reinforcing additives in plastics to give them strength.

Asahi Kasei will examine demand from customers, such as automakers, for CNF products by providing them as samples and use feedback to explore further applications.

The company plans to spend several hundred million yen on the trial production line.

The company recently developed a technology to mass-produce a nonwoven fabric sheet measuring 1 meter in width that can be shipped in rolls.

Although CNF is basically a fiber product, “We’re going to get staff from a wide range of divisions on board to work on the development,” Asahi Kasei President Hideki Kobori said.