Battery-recycling – Harmful-chemicals-plastics 11-06-2022 - Arhive

Battery-recycling – Harmful-chemicals-plastics

Heraeus Holding GmbH, a global Fortune 500 company, announced it has invested substantial equity to take a majority stake in Perpetual Technologies, a leading PET recycling company. To drive global expansion under one brand, Heraeus decided to rename the company Revalyu Resources GmbH.

Revalyu has developed a depolymerisation technology to recycle post consumer PET bottles into esters (monomers), which is the base chemical building block for anything polyester based. Revalyu’s Polymer can be used to manufacture high quality PET products. Today, the company produces filament yarns for the textile industry in its manufacturing facility in Nashik, India. It currently employs around 300 people.

Jan Rinnert, Chairman of the Board of Managing Directors and CEO of Heraeus Holding GmbH says the global strength of Heraeus will provide the investment, infrastructure and strategic support needed to accelerate Revalyu’s growth. “We aim to develop the business into one of the world’s largest and technologically advanced PET recycling companies”, Rinnert added. Battery-recycling – Harmful-chemicals-plastics

“We are a pioneer in recycling PET bottles. After several years of hard work by the team and support from our shareholders and customers, we have built the world’s most innovative, technology leading and environmentally sustainable PET recycling plant in the world based in Nashik, India” said Dr Vivek Tandon, Founder of perPETual Technologies to be renamed Revalyu Resources.

-Chevron and KMG to explore lower carbon opportunities

Chevron Corporation and KazMunayGas (KMG) have announced a MoU to explore potential lower carbon business opportunities in Kazakhstan.

Through its subsidiary Chevron Munaigas, Chevron and KMG plan to evaluate the potential for lower carbon projects in areas such as carbon capture, utilization, and storage (CCUS); hydrogen; energy efficiency and methane management; and carbon financial disclosure methodology. Battery-recycling – Harmful-chemicals-plastics

The MoU was signed by Derek Magness, managing director for Chevron’s Eurasian Business Unit, and Magzum Mirzagaliyev, chairman of the Management Board of KMG.

“Low carbon is a new area for us, and we believe that Chevron’s wide experience in implementing lower carbon technologies and practices in the oil and gas industry will contribute to our capabilities and lead to joint lower carbon projects. We highly appreciate the partnership that has developed over the years of Chevron’s presence in our country,” Mirzagaliyev said.

“Chevron has been investing in Kazakhstan for close to three decades. We are proud of our history of partnership and are committed to investing in the country’s energy future. This MoU with KazMunayGas marks a new chapter in our company’s efforts to support the development of Kazakhstan’s energy sector,” Magness said. “We firmly believe that we can play an important role in the country’s energy transition and achievement of its carbon-reduction targets.

Through our collaboration with KMG, we hope to contribute to providing affordable, reliable, ever-cleaner energy, and help the industries and customers who use our products to advance their lower carbon goals.” Battery-recycling – Harmful-chemicals-plastics

-Thermally Conductive Nylon 6 for Electric Sports Car Component

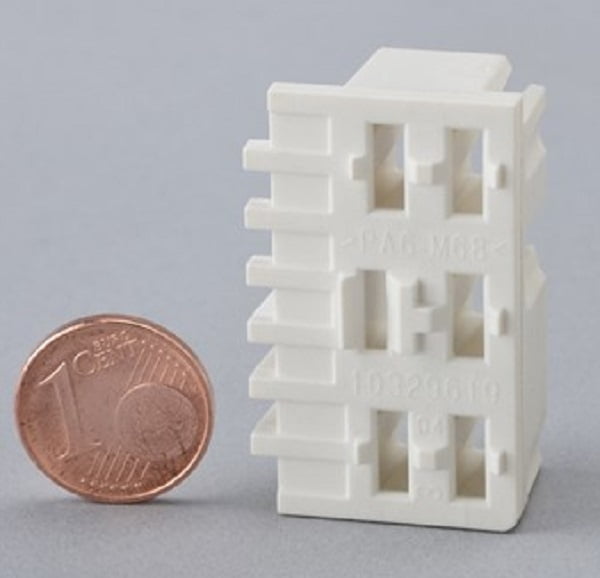

Cooling element for the charge controller of an electric sports car. made from Lanxess’ Durethan BTC965FM30 nylon 6

Thermally conductive plastics are showing significant potential for use in thermal management of charging systems for electric vehicles. One recent example is the charge controller in the fully electric vehicle of a sports car manufacturer based in southern Germany.

This controller contains a cooling element made of the thermally conductive and electrically insulating nylon 6 Durethan BTC965FM30 from Lanxess which dissipates the heat generated in the plug contacts of the controller when charging the batteries. Aside from preventing the charge controller from overheating, this structural material meets the strict requirements for flame-retardant properties, tracking resistance and design, according to technical key account manager Bernhard Helbich

The manufacturer of the entire charging system for the sports car is Leopold Kostal GmbH & Co. KG of Luedenscheid, a global system supplier of automotive, industrial and solar electrics as well as electrical contact systems.

Charge controllers convert the three-phase or alternating current fed in from the charging station to direct current and control the charging process. During the process, they limit the charging voltage and current to prevent overcharging of the battery, for example. Battery-recycling – Harmful-chemicals-plastics

A current with an amperage of up to 48 amps flows through the plug contacts in the charge controller of the sports car, causing significant generation of heat during charging.

“Our nylon is filled with special mineral heat-conducting particles that conduct this heat efficiently away from the source,” says Helbich.

These particles give the compound a high thermal conductivity of 2.5 W/m∙K in the direction of melt flow (in plane) and 1.3 W/m∙K perpendicular to it (through plane).

The Recycling Partnership is pleased to announce the launch of its PET Recycling Coalition, an initiative informed by industry knowledge and expertise to improve PET (plastic #1) circularity. Its work will focus on addressing four key opportunities to increase recycling of this valuable material:

- Increasing the capture of PET bottles

- Broadening the acceptance of PET trays, cups, and clamshells in community recycling collection programs

- Unlocking new supplies of recycled PET (rPET) for packaging manufacturers

- Strengthening recycling systems for pigmented and opaque PET

PET plastic is in high demand for use in textiles such as clothing and carpet (where it is known as polyester) and it’s the most common type of plastic utilized in liquid bottles and food packaging today. While eliminating unnecessary usage is an important component of circularity, increased PET recycling is another critical step in advancing circularity. Battery-recycling – Harmful-chemicals-plastics

This along with company commitments and recycled content mandates in proposed U.S. legislation is leading to skyrocketing demand for recycled PET but supply is currently limited. Most Americans with recycling access are able to recycle PET bottles; however, just 54% can recycle other types of PET packaging like plastic egg cartons and fruit containers. Furthermore, the recycling rate for PET bottles was only 26.6% in 20201. While most PET never makes it into the recycling bin due to insufficient access and participation, as much as 17% of bottles that are recovered are lost at Materials Recovery Facilities (MRFs) due to sortation challenges. By supporting solutions identified by the PET Recycling Coalition, there is a great opportunity to increase recovery and reduce plastic waste and help make progress toward packaging circularity goals.

The PET Recycling Coalition will make grants to recycling facilities for sorting equipment and related capital needs. These upgrades will improve PET bottle capture, deliver more rPET for use back into bottles and thermoforms, increase the acceptance of non-bottle rigid items in community recycling programs, and strengthen recycling opportunities for pigmented and opaque PET. Through grants, technical assistance, and knowledge sharing, the Coalition envisions a thriving PET recycling system that captures significantly more material, enabling more circular PET packaging with increased amounts of recycled content.

-Circular Plastic Taskforce and Digimarc to pilot flexible packaging sortation project

The Circular Plastic Taskforce (CPT) has partnered with Digimarc Corporation to test Digimarc Recycle for optimizing the sortation of flexible plastic packaging in Canada, what the CPT says is a first in North America. This project marks the start of Phase II of the CPT, which aims to carry out or support projects to improve the recycling of all plastic packaging within the evolving Extended Producer Responsibility (EPR) landscape in Quebec and Canada. Battery-recycling – Harmful-chemicals-plastics

With Digimarc Recycle, digital watermarks are applied within the package artwork, no special inks or print process required, and are visible to specialized sorting equipment but imperceptible to consumers. When scanned by machine cameras, the watermarks connect to a cloud-based database containing characteristics of the package, such as the manufacturer and specific product, prior use (food versus non-food), additives or the presence of components that are problematic for recycling. As such, it can help facilitate flexible packaging sortation.

“We are thrilled to launch such a forward-looking project and get our Phase II underway,” says the Circular Plastics Taskforce Steering Committee. “The results from our Phase I study show that even if flexible plastic packaging represents a significant portion of plastic packaging used in Quebec and Canada, their recovery rates remain low. One of the reasons is that today’s sortation equipment cannot distinguish between mono-material recyclable packaging and multi-material structures, therefore lowering bale quality. We believe Digimarc Recycle can help solve this challenge.”

“We are excited to bring Digimarc Recycle to North America and to help the Circular Plastic Taskforce achieve their circularity-driven objectives,” adds Emily Stolarcyk, sustainability program director for business development at Digimarc Corporation. “Digimarc’s digital watermarks, a key component of Digimarc Recycle, have proven to be a truly innovative way to correctly identify each unique package. Connecting watermarks to an extensible database of product and packaging attributes ensures we can help enable a more circular economy now and in the future. This will benefit facilities and brands in meeting their recycling goals, in both the increase of volume and the purity of recycled material.” Battery-recycling – Harmful-chemicals-plastics

-Volkswagen to lead battery recycling research group

The group will develop processes to reuse battery components in a closed loop.

The HVBatCycle research consortium, led by Volkswagen, has been established with the goal of keeping cathode metals, electrolyte and graphite permanently in a closed material cycle (closed loop). The Volkswagen Group, Taniobis GmbH, J. Schmalz GmbH and Viscom AG are working together with researchers from RWTH Aachen University, TU Braunschweig and the Fraunhofer Institute for surface engineering and thin films (IST) for three years to research and develop the necessary processes. The project is funded by the German Federal Ministry for Economic Affairs and Climate Action. Battery-recycling – Harmful-chemicals-plastics

Michael Kellner, a parliamentary state secretary in Germany, says, “European battery production can only be successful if it focuses on sustainability in as many areas as possible. Sustainable batteries are crucial for an energy and transport transition that is guided by high environmental and social standards.”

Sebastian Wolf, chief operating officer battery cell at Volkswagen AG, says, “The recycling of batteries and production rejects makes a decisive contribution to securing the supply of raw materials for our planned factories. Though the HVBatCycle project, a holistic view of the recycling processes and thereby the implementation of the closed loop of battery materials is being prepared.”

In order to have to use fewer materials from primary sources such as mines or salt flats, Volkswagen says essential raw materials can be recovered not just once, but several times. Battery cells made from recycled material are recycled again, proving that multiple recycling runs have no influence on the material quality. Closing the loop requires complex interdisciplinary processes, the company says. For efficient and ecologically and economically sensible recycling, all processes must be coordinated with requirements. Battery-recycling – Harmful-chemicals-plastics

The consortium project focuses on the mechanical-hydrometallurgical recycling route, which Volkswagen says is characterized by low energy requirements and the possibility of a comparatively simple decentralized distribution of certain recycling processes in Europe. This favors a local circular economy and secures strategically important raw materials, which significantly reduces Europe’s dependence on other regions of the world. The HVBatCycle project aims to identify efficient processes and innovative solutions that ensure the establishment of an end-to-end value chain with high economic efficiency while also maximizing recycling and energy efficiency and minimizing environmental impact.

-Plastic pollution: harmful chemicals in our plastics

Global cumulative plastic production is predicted to reach 34,000 million tonnes between 1950 and 2050.

The harmful chemicals released from plastic products throughout their entire life cycle can pose a serious risk to humans and the environment, particularly when waste is not properly managed, finding its way to air, water and soils.

While the preparations for the legally binding agreement on plastic pollution are ongoing, the plastic waste and chemicals in plastics are being discussed at the 2021/2022 meetings of the conferences of the Parties to the Basel, Rotterdam and Stockholm conventions, including the Plastic Forum from 8 and 10 June 2022 in Geneva, Switzerland. Battery-recycling – Harmful-chemicals-plastics

-Biden administration, EPA announces $375M in funding for recycling and waste prevention initiatives

The funding will develop several new initiatives, including a solid waste Infrastructure for recycling grant programs and recycling education and outreach grant programs.

The U.S. Environmental Protection Agency (EPA) announced $375 million in funding through President Joe Biden’s Bipartisan Infrastructure Law for recycling, reuse and waste prevention programs. Battery-recycling – Harmful-chemicals-plastics

The EPA published three requests for information (ROI) seeking input on the design of these new materials management initiatives, the first step in the process to implement the largest EPA investment in recycling in 30 years.

“Too many communities are burdened by pollution and the negative environmental and health impacts that result from poorly managed waste,” EPA Administrator Michael S. Regan says. “This unprecedented investment from President Biden’s Bipartisan Infrastructure Law will transform recycling and solid waste management across the nation, create good-paying jobs and advance our bold environmental agenda as we work to build a better America.”

The $375 million in funding will develop several new initiatives, including a solid waste infrastructure for recycling grant program, a recycling education and outreach grant program and a model recycling program toolkit. It also will provide funding to compile best practices for battery collection, recycling and labeling guidelines.

Through education and outreach grants, the EPA can fund projects like public service announcements, advertising campaigns and the development and dissemination of recycling program toolkits. These activities enable the agency to improve consumer education and outreach on how to correctly recycle, reduce contamination in the recycling stream, produce higher quality recycled materials and advance a circular economy. A circular economy reduces material use, redesigns materials to be less resource-intensive and recaptures “waste” as a resource to manufacture new materials and products. Battery-recycling – Harmful-chemicals-plastics

Battery-recycling – Harmful-chemicals-plastics