Biodegradable Plastics Polylactic Acid 30-11-2021 - Arhive

Biodegradable Plastics Polylactic Acid

Crude Oil Prices Trend

-Microwave-induced pyrolysis is driving the advancement of chemical recycling

Greenback Recycling Technologies partnership provides solution for processing low-density plastic packaging waste

Greenback Recycling Technologies is on a mission to solve the global plastic waste crisis. The UK based company specializes in implementing scalable and distributed advanced collection and recycling solutions that offer brand owners and the plastics value chain fully traceable recyclate. Using blockchain-based evidence to trace and authenticate the provenance and composition of materials, it enables waste plastic to more efficiently be used as a feedstock for food-grade commercial packaging applications, at predictable prices and in dependable quantities.

“We are building a decentralised network of collection and recycling plants near sources of post-consumer plastic waste around the world,” explains Philippe von Stauffenberg, Greenback CEO. “Through the use of smart contracts, we ensure a fair distribution of value to all actors in the supply chain, including the informal waste collection sector.”

Recently, the company incorporated microwave-induced pyrolysis technology into its lineup of solutions for managing plastic and packaging waste. The process, developed by the UK-based chemical recycling technology specialist, Enval, is a proprietary solution for processing low-density plastic packaging waste, enabling thermochemical decomposition of organic material at elevated temperatures, in the absence of oxygen. According to von Stauffenberg, it has fantastic potential for recycling mixed plastic waste that cannot otherwise be economically physically separated and classed.

What is microwave-induced pyrolysis?

Enval’s microwave-induced pyrolysis technology used by Greenback has been developed specifically for the recovery of complex plastic packaging, and can handle a wide range of materials, including multi-layer (foil/film) laminates. Von Stauffenberg explains that when carbon is exposed to a microwave field, it can reach temperatures of up to 1,000°C in just a few minutes. If shredded plastic waste is then mixed with the carbon, the energy absorbed from the microwaves is transferred to the plastic by conduction in a quick and efficient manner. As the packaging travels through the oven, the plastic, glue and ink layers degrade via the pyrolysis process to form a mixture of hydrocarbons, ranging from C3 to C20.

“This mixture, which is a gas inside the oven, exits and is then cooled down and separated into two fractions: gas and oil – referred to as Py-Oil,” continues von Stauffenberg. “The gas is used to generate the electricity required to power the process, and the condensed oils can be used as the feedstock to produce new plastic.” He adds that a single microwave-induced pyrolysis module can process 2.5kt per annum of hard-to-recycle plastic waste, and can scale in 2.5kt increments, to fit the size of the waste stream available.

-Biobased and Biodegradable Plastics | Knowledge Hub for Green Technologies

n the first place. But how to do this? What policy options exist and have proven effective to prevent single-use plastics? What are experiences of practitioners that are subject to those policies, and how do they implement them in their operations?

Disposable, single-use packaging is convenient from the perspective of consumers, e.g. take-away food packaging. However, the high amounts of plastic consumed entail various negative impacts. In the dilemma between ecological perspectives on single-use plastic and the convenience that biobased and biodegradable plastic packaging offers, this type of plastics has been discussed as an alternative to fossil-based plastics for quite some time. Environmental benefits are often attributed to biobased and biodegradable plastics due to the fact that “bio” is understood to mean “environmentally friendly”. They are perceived as suitable substitutes for the conventional plastics whose environmental impacts have been widely researched. However, this supposed solution implies various consequences and problems. A one-to-one substitution of conventional plastic with biodegradable or biobased plastic does neither lead to any changes in waste volumes nor to a reduction of the associated environmental impacts in the long run.

This episode of the dialogue series provides science-based background knowledge on biobased and biodegradable plastic. The speakers’ input shall enable the partners to avoid regrettable substitution, aims to raise awareness for the need to consider the trade-offs and anticipate consequences of material decisions, in terms of environmental impacts and end-of-life treatment.

The dialogue series is part of the project “Collaborative Action to Reduce Single-Use Plastic in South-East Asia (CAP SEA)”, which is part of a global project “Export Initiative for Green Technologies” commissioned by the German Ministry of the Environment (BMU).

-Pet prices leap higher in Europe

This week, PET resin bottle grade prices bolstered higher in Europe. Prices spiked, as product availability continued to remain tight in the region.

Reports of persistent stronger regional buying sentiments further contributed to the price rise.Biodegradable Plastics Polylactic Acid

In the contract markets, bottle grade PET prices were assessed at the Euro 1560-1565/mt FD North West Europe levels, a week on week spike of Euro (+50/mt).

In the spot markets, FD North West Europe PET prices were assessed at the Euro 1580-1590/mt, a surge of Euro (+65/mt) from last week.

Upstream MEG spot prices were assessed at the Euro 940-945/mt FD North West Europe levels, unchanged from the previous week.

Meanwhile, in Asia, PET prices were assessed at the USD 1080-1130/mt FOB North East Asia levels, a sharp week on week decline of USD (-40/mt).

-PE track the movements of feedstock

Recently, polyethylene market keeps in range-bound, the overall trend is relatively weak and one of the main factors affecting the market is the fluctuation of upstream raw material prices. As the feedstock coal and crude oil have seen large declines in a short period of time, the PE market, which is greatly affected by fluctuations in the cost, has also fallen. Biodegradable Plastics Polylactic Acid

From the perspective of coal, with the gradual implementation of the national coal control policy, the price of thermal coal continues to decline, and the cost of coal-based polyethylene shows a downward trend. The profits of coal-based PE has rebounded significantly compared with the previous low. In the near future, coal price is in narrow range-bound, and the cost of coal-based polyethylene has temporarily entered a relatively stable stage. In the late period, traders are still suggested to pay attention to whether there is still a further downward trend in coal.

From the perspective of crude oil, as OPEC+ and IEA predict that the supply of crude oil continues to recover, crude oil may turn into a surplus pattern as soon as the end of 2021. In addition, the United States and some other countries have planned to release strategic petroleum reserve (SPR) and put it on the agenda. Moreover, the Federal Reserve’s Taper has led to the strengthening of the US dollar. Therefore, international oil prices have fallen sharply. Recently, US has announced to sell crude oil from strategic petroleum reserve and the overall release scale is far less than market expectations, and thus oil price moves higher slightly. However, the overall upward space for oil prices is not large, and oil price may maintain in consolidation in the short term, waiting for the response of the OPEC+. Therefore, in the short term, with the supply and demand side of polyethylene remaining stable, oil and coal prices have a considerable impact on polyethylene market, especially when oil prices enter the point of time when they turn from strong to weak, it is particularly important to pay attention to the changes of the raw material end.

-Simulation Shows Recycled Polyamides Can Sustain Future Mobility

Extensive simulation-ready material performance datasets boost confidence in sustainable grades.

Domo Chemicals has introduced new material cards to fast-track the adoption of its line of eco-friendly polyamides (PAs), Techyl 4Earth. This new feature in Domo’s advanced predictive simulation platform, MMI Techyl Design will help manufacturers to develop lighter, more cost-effective parts using peak-performing recycled polyamides. Biodegradable Plastics Polylactic Acid

With many industries eager to reduce their environmental footprint, demand for recycled plastics is growing exponentially. Until recently, however, the often-inconsistent performance of recycled plastics hindered their adoption in the most rigorous applications. Techyl 4Earth has opened the door to a suite of new applications, providing breakthrough performance comparable to traditional PA 66. With Techyl 4Earth, Domo’s goal is to accelerate the use of sustainable plastics and broaden the scope of target applications by providing top-performing grades to meet the most demanding technical requirements.

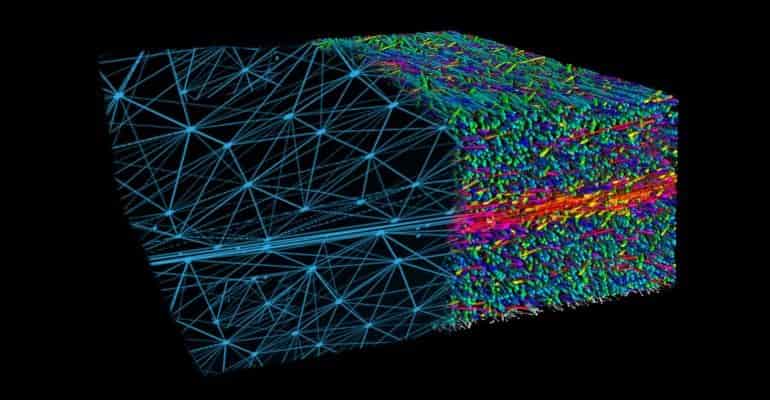

If automakers are to adopt eco-friendly metal-replacement PAs, however, engineers need to have confidence in their material performance. With Domo’s MMI (Multi-scale modelling, Mechanical simulation, and Injection molding) Techyl Design tools, manufacturers can understand how these new materials will behave in real-life situations before putting new parts into production.

MMI Techyl Design is an advanced predictive platform that harnesses Domo’s extensive database of key material property measurements to help engineering teams develop lighter, more cost-effective parts using its Techyl polyamide materials. This solution is powered by Digimat, a material modeling software developed and supported by Integrated Computational Materials Engineering (ICME) experts from Hexagon’s Manufacturing Intelligence division. It simulates a wide range of in-use conditions to accurately predict the performance of injection-molded parts using Domo-validated digital material cards.

-Conference focuses on plastic recycling in Asia

January China & Asia Circular Plastics Summit 2022 event looks at plastic recycling opportunities in the approaching years.

The two-day China & Asia Circular Plastics Summit 2022, taking place Jan. 12-13, will focus on plastic recycling market trends in that part of the world, according to conference organizer Apex International.

Presentations at the event will offer forecasts through 2024, including a forecast for plastic scrap’s market share; plastic packaging design and innovations intended to reduce the cost of recycling; and “building a circular value chain for [the] chemical recycling of plastics.” Biodegradable Plastics Polylactic Acid

Other topics addressed include advances in injection molding tied to plastic recycling, potential circular economy systems in health care plastics and other aspects of the closed loop plastics supply chain.

“Addressing the [recycling] challenge requires engaging the entire plastics value chain, from polymer manufacturers to brands to waste haulers, in order to create truly systemic solutions,” states Apex in its conference background description.

Sponsors of the event include petrochemical firms Dow and Total and Finland-based scrap-to-fuels company Neste. Presenters are drawn from a wide variety of companies, including IHS Markit, Danone, Tupperware and the China Plastics Reuse and Recycling Association (CPRRA).

The conference is taking place at the Parkline Century Park Hotel in Shanghai. However, overseas attendees currently face a 21-day quarantine to enter the People’s Republic of China. Thus, Apex says it is offering a “hybrid” that also allows those registering to attend in an online format.

More information on the two-day conference can be found on this web page.

-Hot sales of polyester yarn will not last long

PSF futures surged on Nov 24 and the sales of direct-spun PSF improved much with sales ratio averaging over 500%. On the next day, direct-spun PSF price moved up, but the sales ratio still reached 110%. Why is it sold better when the price moves up, different from PFY’s better sales when price is lowered?

With the doubt, let’s starting recent market performance. After National Day holiday (Oct 1-7), direct-spun PSF and polyester yarn both moved into the valley. Their prices and trading volumes kept shrinking in over a month. Amid the bearish sentiment, buying interest was thin. Downstream spinners and traders only procured for their rigid demand. After a month’s digestion of raw materials, no matter traders or spinners all have demand for replenishment, but they are just seeking an opportunity for proper price.

The turning point came when crude oil rocketed on Nov 23. Previously, with concerns that US would release strategic oil reserves with India, Japan and South Korea, WTI crude oil declined to $75/b. However the specific volume released was not as much as expected, which also stimulated OPEC+ to consider suspension of production increase, and thereby crude oil was pulled up to $78-79/b. Then overnight PSF futures soared. Meeting replenishment demand, the sales ratio of direct-spun PSF rushed up. The average inventory of direct-spun PSF plants also dropped to about one day, easing the pressure.Biodegradable Plastics Polylactic Acid

But, does polyester yarn sales turn so hot? Does the restocking point also come?

First, the sales are not as expected with raw materials moving up. Take Fujian, major consumption area of direct-spun PSF 1.4D, as an example. The sales ratio of polyester yarn in Fujian averaged at 200-300% on Nov 24, and about 150% on Nov 25. That seemed to be improved much from a month ago, but still fell far behind direct-spun PSF, and this improvement was based on the rise of raw materials, so once the favorable factor diminishes, the demand will disappear immediately. On the other hand, except Fujian and the variety, other products like polyester sewing thread, polyester/cotton yarn and vortex-spun polyester yarn in other markets keep dull. The export orders are also plain as usual.

-UK carpet maker Victoria to buy rugs division of Belgium’s Balta

Flooring products maker Victoria Plc said on Monday it would buy the rugs division along with UK polypropylene carpet and non-woven carpet businesses of Belgium’s Balta Group NV for 138 million euros ($155.50 million).

Victoria, the largest carpet maker in the UK, said it would fund the deal entirely from its existing financial resources and the acquisition would be immediately earnings accretive.Biodegradable Plastics Polylactic Acid

UK carpet maker Victoria

Established in 1895 and listed since 1963 (on AIM since 2013), Victoria PLC is an international manufacturer and distributor of innovative flooring products. The Group designs, manufactures and distributes a range of carpet, ceramic and porcelain tiles, underlay, LVT (luxury vinyl tile), artificial grass and flooring accessories, aimed at the middle-to-upper segment of the market. It is the largest manufacturer of carpet in the UK and the second largest in Australia, as well as the largest manufacturer of underlay in both countries. Victoria Carpets was awarded the Queen’s Royal Warrant in 2013.

Balta carpet

Balta carpets develops carpet tiles for residential use, as well as tufted, woven and non-woven broadloom carpets for residential, commercial and event applications. Our colours, styling and features always meet the needs of each project and customer: we deliver any volume of state-of-the-art carpets across a broad range of entry to premium solutions. In Europe, Balta carpets is the clear market leader for tufted and woven wall-to-wall carpet.

-Car parts group Faurecia cuts 2021 guidance for second time

- Cuts 2021 sales outlook to 15-15.5 bln euros

- Issues big cut to net cash flow target

French auto supplier Faurecia (EPED.PA) cut its full-year guidance for a second time on Monday, citing a drop in European car production, the impact of supply bottlenecks and COVID restrictions on operations and one-off costs in the United States.

Shares in Faurecia were down 6.6% at 0907 GMT after the outlook revision.

The downgrade was made after research institute IHS Markit, on which Faurecia bases its own sales projection, said this month that worldwide car demand in the second half of 2021 would shrink by 13% to 6.8 million produced vehicles, down its previous forecast of 7.8 million vehicles.

Faurecia also took into account an increased risk of COVID-19-related production declines as Europe faces a new wave of infections and a new variant of the virus was detected.

“We had a positive trend in November,” Chief Financial Officer Michel Favre said in a conference call shortly after the statement, “but on the other hand (…) we have no clue that we won’t have some early closures in the first week of December.”

Favre said that new COVID-19-related risks added to an already strained situation due to component inflation, mainly affecting semiconductors and continued operating problems at a plant in Michigan, the United States, which had forced the company to slow down production currently to 80% of capacity.

Biodegradable Plastics Polylactic Acid

PET Bottle Nylon RPET Carbon Fiber Polyester Plastic Recycling 29-11-2021