PET waste recovery

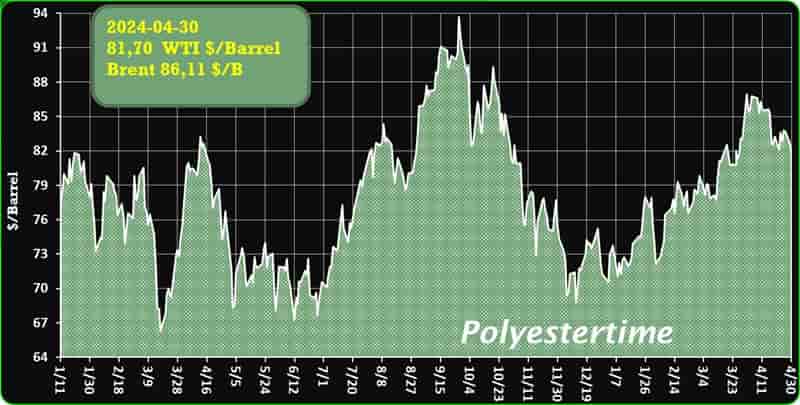

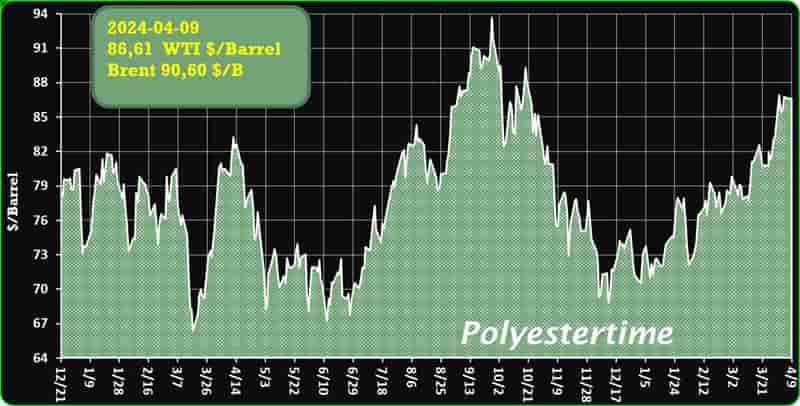

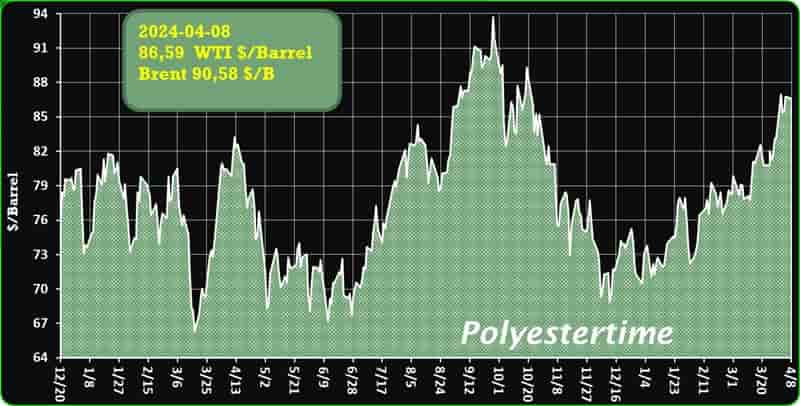

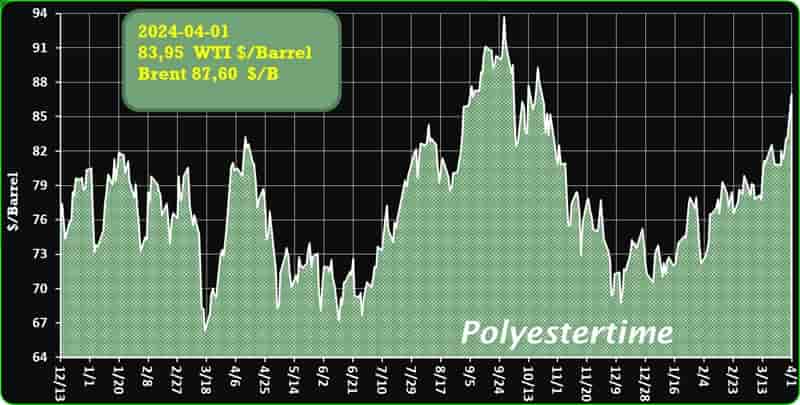

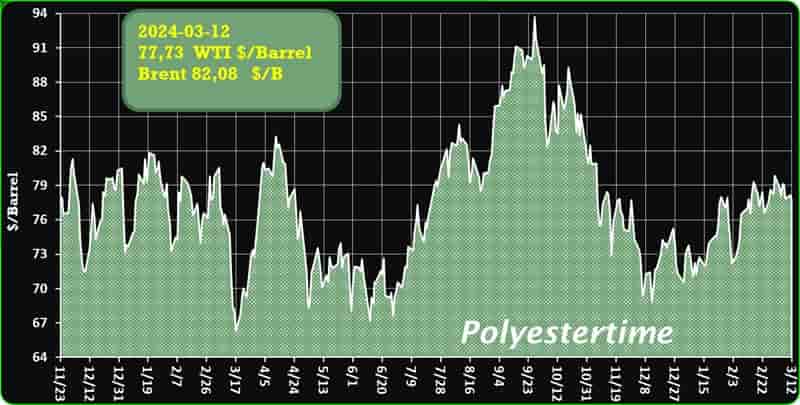

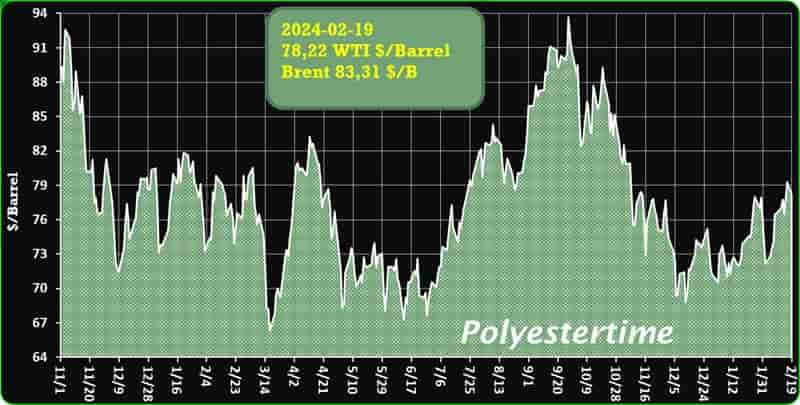

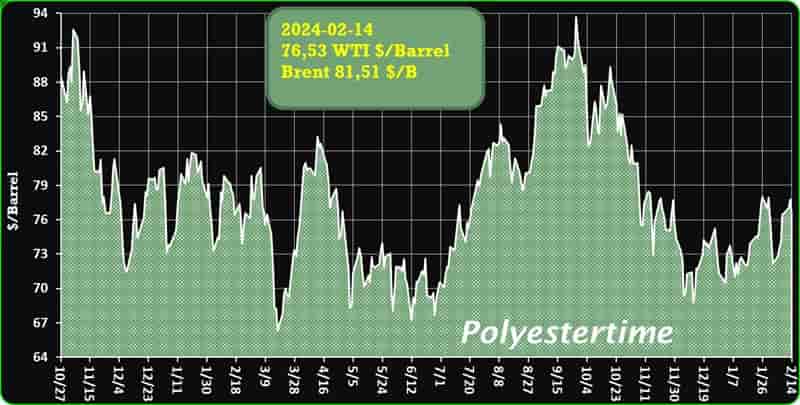

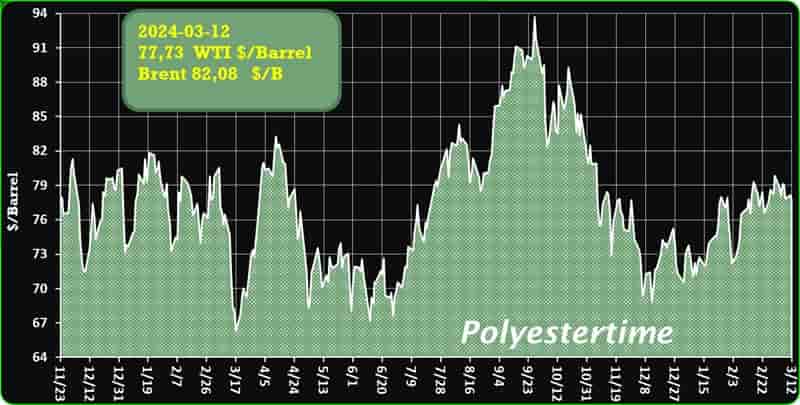

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Amut, the renowned Italian manufacturer of extrusion and recycling plants headquartered in Novara, is actively engaged in initiatives aimed at PET recovery across Latin America

Their latest endeavors involve the establishment of three cutting-edge recycling facilities in Peru, Colombia, and Guatemala.

In Lima, Peru, Amut has successfully completed the installation and activation of the initial line, boasting a substantial capacity of 6,000 kg/h. This facility, situated within the region’s largest plastic recycling plant, caters specifically to the production requirements of rPET bottles, meeting the demands of the market effectively.

Meanwhile, in Guatemala City, Central America, a comprehensive sorting and washing solution with a capacity of 3,000 kg/h is currently under construction. Simultaneously, in Bogota, Colombia, progress is well underway for a comparable line with an equivalent capacity. PET waste recovery

The innovative lines supplied by Amut represent a fusion of superior production capacity and impeccable flake quality. This combination renders them ideal for closed-loop applications, particularly in bottle-to-bottle recycling scenarios where the rPET resin necessitates subsequent regrading processes.

Amut’s commitment to revolutionizing recycling practices in Latin America underscores its dedication to sustainability and environmental stewardship on a global scale. Through these strategic endeavors, the company aims to significantly contribute to the advancement of PET waste recovery in the region, fostering a more eco-conscious and circular approach to plastics management. PET waste recovery

Pyrum Innovations AG and GreenTech Recycling Tires AB have set their sights on Sweden for their latest venture: a state-of-the-art recycling plant

The two companies have inked a contract to spearhead the development of a groundbreaking facility capable of handling 20,000 tonnes of end-of-life tires annually. This strategic move not only marks Pyrum’s pivotal entry into the Scandinavian market but also signifies a significant milestone for GreenTech in its tire recycling endeavors.

The groundwork for this ambitious project has already been laid, with the formalization of a consulting agreement between GreenTech Recycling Tires AB and Pyrum Innovations AG. Under this agreement, Pyrum will contribute up to EUR 3 million to the Special Purpose Vehicle (SPV), contingent upon GreenTech securing full financing. Negotiations are underway to secure the necessary funding, while GreenTech has secured a suitable site in Billingsfors, Sweden, and initiated discussions with tire suppliers. PET waste recovery

Anticipated to commence operations in 2027, the plant will utilize Pyrum’s cutting-edge pyrolysis technology to recycle end-of-life tires efficiently. Pascal Klein, CEO of Pyrum Innovations AG, expressed his enthusiasm for the collaboration, highlighting its significance in penetrating the Scandinavian market.

Per-Olov Lindgren, Chairman of the Board of GreenTech Recycling Tires AB, emphasized the ecological importance of their partnership with Pyrum, emphasizing their commitment to a circular economy. With plans in place for tire-to-tire recycling, as well as the production of plastics and steel products, GreenTech aims to close the loop on tire waste.

This venture marks Pyrum’s third contractual agreement for constructing a recycling plant, in addition to projects in Greece and the Czech Republic, cementing its position as a leader in tire recycling technology. PET waste recovery

Indonesia withdraws import mandate for key PE, PP

The Indonesian trade ministry has withdrawn the enforcement of a mandatory import quota for most polyethylene (PE) and polypropylene (PP) grades, along with polystyrene, polyethylene terephthalate and monoethylene glycol, which was previously expected to take effect on 10 March.

The official announcement was made on 6 March and supported with a decree released today, seen by Argus. Market participants have waited for an official statement following a semi-official announcement by the trade ministry on 29 February.

Imports of PP co-polymers will still require an import quota, which has been in force for years. The latest requirement of an additional surveyor report from 10 March has also been withdrawn. PET waste recovery

The trade ministry announced on 11 December that domestic PE and PP importers will need to apply for specific quotas to be able to import polymer resins from 10 March, or risk cargoes being rejected during customs clearance.

Indonesia’s PE and PP import dependency and the short-notice enforcement have led to objections by local and international associations, with disrupted resin supplies likely to cause a significant impact on the production and competitiveness of finished plastics. The enforcement was earlier expected to be delayed possibly by at least three months, based on local associations’ appeal requests to the trade ministry. PET waste recovery

Texcyle Adopts Sustainability With Bio-Elastane In The Socks Industry

Texcyle, a pioneering Indian sock supplier, officially launches into the global market, proudly introducing the first-ever use of Bio-Elastane in the production of socks. Founded in 2023 by Raunak Hasnani, an ambitious entrepreneur with a passion for revolutionising the sock industry, Texcyle is committed to producing 100% organic socks and partnering with brands dedicated to sustainable and ethical practices.

Texcyle’s mission goes beyond just providing socks; it aims to eliminate greenwashing claims in the fashion industry by offering a transparent and eco-friendly manufacturing process. The company’s unique selling point lies in its dedication to a low carbon footprint, top-notch quality, and customization services. PET waste recovery

The socks produced by Texcyle are crafted from a combination of Organic Cotton, Recycled Polyester, and revolutionary Bio-Elastane, making them pioneers of low carbon footprint socks. The company ensures a sustainable manufacturing process from start to end by sourcing ethical and certified materials. Texcyle has also taken a bold step towards sustainability by eliminating all virgin plastic packaging for shipping and distribution, replacing it with eco-friendly alternatives such as recycled paper, cotton, and compostable plastic.

More…

TotalEnergies and Sulapac to offer packaging for cosmetics industry

Sulapac will be incorporating TotalEnergies’ recycled biodegradable biopolymers into cosmetic packaging.

TotalEnergies Crbion has entered into a strategic alliance with Finland-based company Sulapac to advance the use of recycled and biodegradable materials in cosmetic packaging.

This collaboration aims to drive sustainable innovation by offering eco-friendly packaging solutions without compromising on quality.

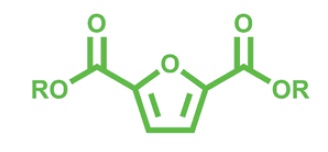

The two companies intend to address the industry’s dilemma of choosing between biobased, biodegradable materials and recycled alternatives by offering Luminy polylactic acid (PLA) bioplastics technology. PET waste recovery

Developed by TotalEnergies Corbion, Luminy is a range of specially developed PLA polymer resins derived from renewable resources.

The company offers its Luminy PLA portfolio, comprising both high heat and standard PLA grades, for various industries, from packaging to consumer goods.

Sulapac will be incorporating TotalEnergies Corbion’s recycled biodegradable biopolymers into specific material grades, facilitating the integration of sustainable elements into cosmetic packaging. PET waste recovery

Additionally, Sulapac plans to support the recycling initiative by collecting and supplying waste materials to TotalEnergies Corbion and promoting a circular economy system.

More…

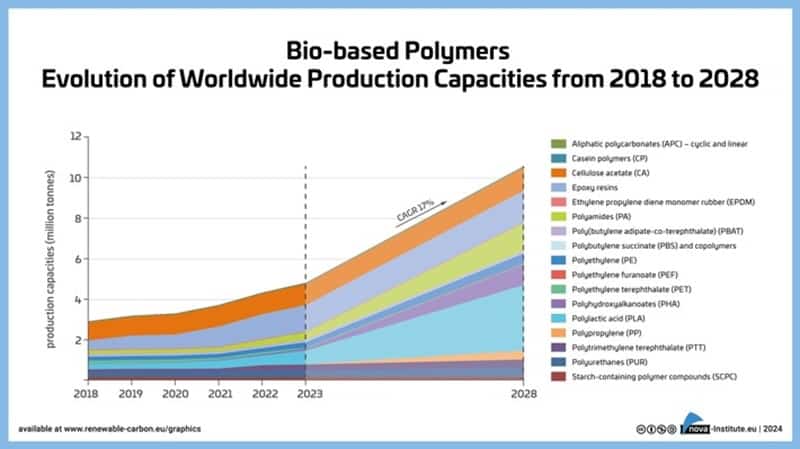

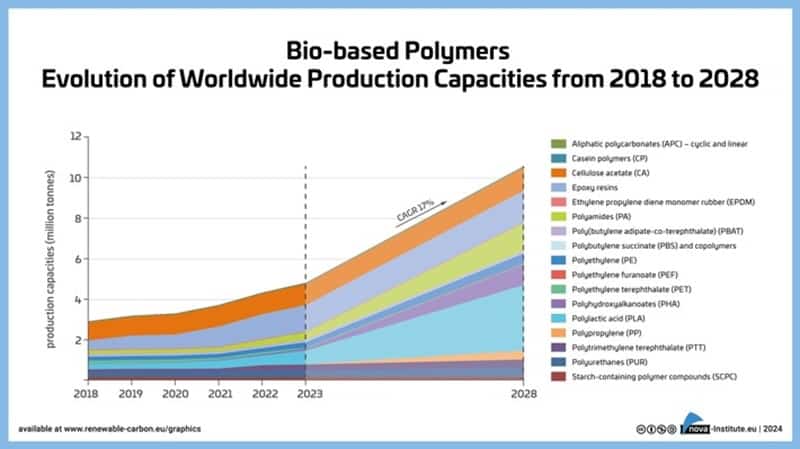

Current market study forecasts annual growth of 17 % for bio-based polymers between 2023 and 2028

Demand from Asia and the USA in particular is driving growth, Europe is lagging behind.

Current market study forecasts annual growth of 17 % for bio-based polymers between 2023 and 2028. Demand from Asia and the USA in particular is driving growth, Europe is lagging behind. PET waste recovery

New report released on the global bio‑based polymer market 2023 – a deep and comprehensive insight into a dynamically growing market

The year 2023 was a promising year for bio‑based polymers: PLA capacities have been increased by almost 50 %, and at the same time polyamide capacities are steadily increasing, as well as epoxy resin production. Capacities for 100 % bio-based PE have been expanded and PE and PP made from bio‑based naphtha are being further established with growing volumes. Current and future expansions for PHAs are still on the horizon. After hinting at a comeback in 2022 bio-based PET production dropped in 2023 by 50 %.

In 2023, the total production volume of bio‑based polymers was 4.4 million tonnes, which is 1 % of the total production volume of fossil‑based polymers. PET waste recovery

The CAGR of bio-based polymers is, with 17 %, significantly higher than the overall growth of the polymer market (2–3 %) – this is expected to continue until 2028 (Figure 1).

The new market and trend report “Bio‑based Building Blocks and Polymers – Global Capacities, Production and Trends 2023–2028”, written by international biopolymer expert group of the nova-Institute, shows capacities and contains production data for 17 commercially available, bio‑based polymers in the year 2023 and a forecast for 2028.

More…

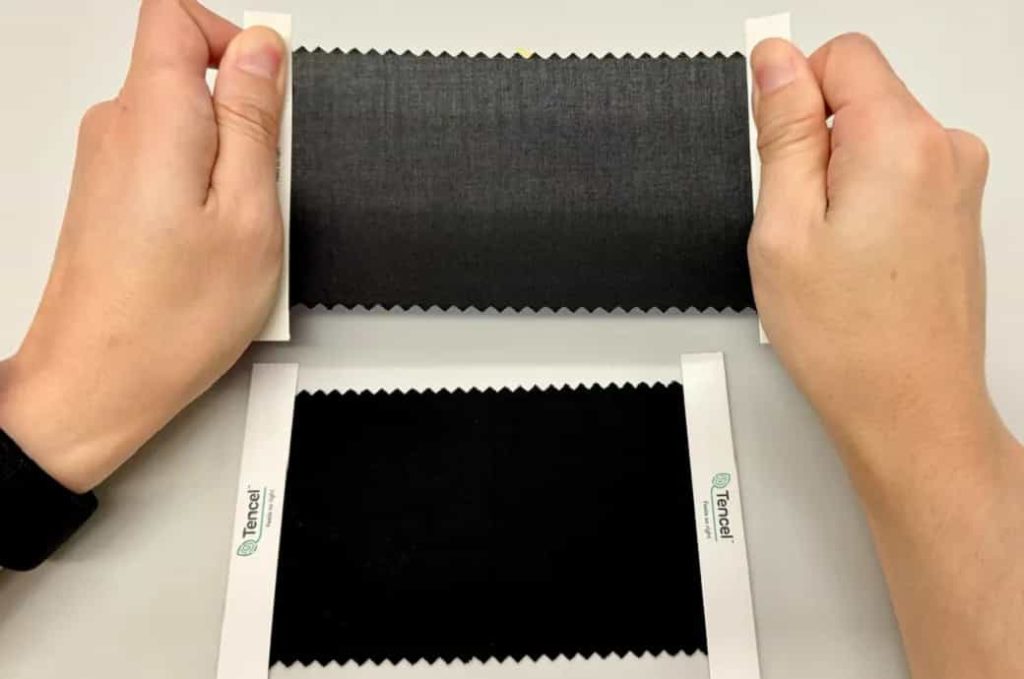

Homeboy Threads and TOMRA demonstrate textiles sorting unit to policymakers, fashion brands

TOMRA whitepaper highlights current state of textile recycling and strategies for a circular value chain

Homeboy Threads, the California Product Stewardship Council, the City of Los Angeles Sanitation and Environment Department (LASAN), and TOMRA have hosted an event in the City of Commerce, California, where they were joined by environmental advocates, fashion brands, and policymakers who are working to build circular economy partnerships in Los Angeles, create quality jobs, and reduce the harmful impact of textile waste.

In 2022, a Textile Recovery Pilot Report found that every year, more than 70,000 tons of commercially generated textile waste ends up in Los Angeles area landfills.

The event included demonstrations of a TOMRA Recycling unit that relies on sensor technology to sort textiles by fibre and colour at high volumes. PET waste recovery

In collaboration with textile recycling partners like Homeboy Threads, the TOMRA Recycling unit presents a solution to an otherwise labour-intensive process required to sort textiles by fibre type. By providing pure cotton material to emerging fibre-to-fibre recyclers and clothing manufacturers, the unit has the potential to change the apparel industries’ current take, make, and waste chain, and create a closed-loop textile waste recycling model that protects the environment. PET waste recovery

More…

Polymers prices – PET bottles banned? the environment doesn’t always thank you 11-03-2024

PET waste recovery