ChemicalRecycling PETBottle Polyesterfibers 15-04-2021 - Arhive

ChemicalRecycling PETBottle Polyesterfibers

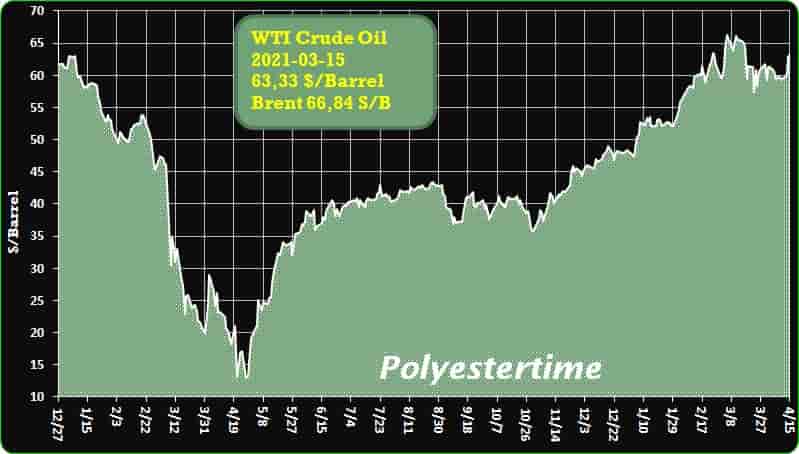

Crude Oil Prices Trend

-American biotechnology company Occidental will build a bioethylene production facility

Occidental Petroleum subsidiary Oxy Low Carbon Ventures (OLCV) and biotechnology firm Cemvita Factory are planning to build a bioethylene production facility that will produce monomer from artificial carbon dioxide (CO2), the company said.

The pilot plant will have a capacity of 1 ton per month and will produce bioethylene using artificial carbon dioxide, water and light. Production is due to start in 2022. The companies did not say where the plant will be built. The technology is competitive with ethylene derived from hydrocarbons, although the company did not specify prices.

If successful, the project could provide Occidental with another source of ethylene, which it uses to make polyvinyl chloride (PVC), said Robert Zeller, vice president of technology for OLCV.

The process being developed by Cemvita and OLCV is not the only one that can produce ethylene from artificial carbon dioxide.

For over a decade, the Brazilian polyolefin manufacturer Braskem has been producing ethylene by dehydrating ethanol at its Triunfo facility in the state of Rio Grande do Sul. Braskem previously announced plans to expand the plant’s capacity.

Ethylene is the main raw material for the production of polyethylene (PE).

-In China for China: Clariant Additives steps up at Chinaplas 2021

New additives solutions make regional debut for packaging & greenhouse films

More support for sustainable innovation in China’s plastics industry & application sectors ChemicalRecycling PETBottle Polyesterfibers

Building a footprint for collaboration and tailored solutions

At Chinaplas 2021, Clariant will debut new high-end sustainable additive solutions for plastics to support local manufacturers in adapting quickly to the requirements of highly-demanding new applications and environmental goals (Booth 15E39).

As China embraces new sustainability targets, its manufacturing segments are adopting a more environmentally-considerate approach to innovation and answering application trends. In response, Clariant is increasing local access to performance-boosting, resource-efficient additives encouraging reduction, re-use and recycling of plastics. As well as greater use of renewable feedstocks and biopolymers for more applications. All part of a wider stepping up of its local production footprint and collaborative, joint development focus to help the plastics value chain advance technology, performance and the shift to circularity in China’s growth markets.

-Viridor and Tomra collaborate on Scottish DRS project

Viridor and Tomra have formed a partnership in a bid for the design, build and operate the Scottish deposit return scheme (DRS) counting and sorting centres.

Scotland is set to launch a DRS initiative in 2022, which it hopes will drive collection rates on drinks containers to levels in excess of 90 per cent, reducing littering and contributing to net zero climate goals. The counting and sorting centres represent a critical part of the infrastructure required to underpin the efficient and accurate function of the DRS. ChemicalRecycling PETBottle Polyesterfibers

Viridor’s director of business development (Polymers), Luke Burgess, said: “Viridor, has a long history of investing in Scottish recycling infrastructure, and the DRS offers the opportunity to supplement that investment and contribute to green job creation and the development of a truly circular economy.

Cooking up your dish of instant noodles or soup could soon get even faster: the all-important tastemaker, which now comes packaged in aluminum foil pouches, could soon be marketed in sachets that could be eaten.

Having developed the technology for the preparation of edible, biodegradable and functional seaweed film using red seaweed (Kappaphycus alvarezii) and green seaweed (Ulva lactuca), scientists at the Visakhapatnam Research Centre of the Central Institute of Fisheries Technology (CIGF) are in the final stages of offering this technology for commercial production. ChemicalRecycling PETBottle Polyesterfibers

While the technology to use edible biopolymers and biodegradable films and sachets from macroalgae or seaweed in the food industry isn’t new — it was famously used for the first time in the 2019 London Marathon, when runners going past Mile 23 were handed out edible sachets containing a Lucozade energy drink which they could either swallow or discard — this is arguably the first time this revolutionary technology has been developed in India. The environmental advantages of using edible sachets can be gauged from the fact that while these sachets biodegrade in four to six weeks, a plastic water bottle takes approximately 450 years to biodegrade completely.

-EU Plastics Converters Sound Alarm over Resin Shortages and Soaring Prices

The proverbial rising tide that lifts all boats doesn’t seem to be working out for Europe’s plastics converting industry. The sector is experiencing “severe shortages of raw materials and [unprecedented] price increases,” according to the European Plastics Converters (EUPC) association. The shortages are caused by an “improving global economy” combined with exports of material to Asia and North America, according to EUPC, which is driving up prices.

The predicament is having a significant impact on small to medium-size (SME) businesses, which are fighting for their economic survival, said EUPC in a press release distributed today. Manufacturers of plastic products across Europe have suffered from bottlenecks in the materials supply chain since the beginning of the year, affecting polypropylene, polyethylene, PVC, along with other plastics and additives. The disruption, added the EUPC, is a manifestation of Europe’s supply/demand imbalance. ChemicalRecycling PETBottle Polyesterfibers

-Honeywell technology selected for US carbon capture project set to produce clean hydrogen

Honeywell UOP technologies have been selected to capture and sequester up to 1.65 million tonnes of carbon dioxide (CO2) annually and produce clean hydrogen energy from a repurposed gasification plant in West Terre Haute, Indiana.

Wabash Valley Resources selected the technology for the project which is expected to be one of largest carbon sequestration initiatives in the US to date.

Under the contact, UOP will provide technology licenses, basic engineering, and specialty equipment including a modular MOLSIV™ molecular sieve dehydration unit, modular Ortloff CO2 Fractionation unit, and Polybed™ pressure swing adsorption (PSA) unit to sequester CO2 and process synthesis gas from the gasification unit.

The Ortloff CO2 Fractionation technology will produce a high-purity liquid CO2 stream while separating a hydrogen-rich stream that will be purified by the PSA unit.

The CO2 stream will be sent for permanent geological storage, while the hydrogen stream can fuel a hydrogen turbine to generate electrical power. The hydrogen stream can also be used in chemical synthesis or marketed as a clean transportation fuel. ChemicalRecycling PETBottle Polyesterfibers

-Microplastics in our air ‘spiral the globe’ in a cycle of pollution, study finds

CNN — Tiny bits of plastic from your packaging and soda bottles could be traveling in the atmosphere across entire continents, carried by winds, a new study found.

Most of our plastic waste gets buried in landfills, incinerated or recycled — but up to 18% ends up in the environment. Since plastic isn’t easily decomposable it instead fragments into smaller and smaller pieces until the microplastics are small enough to be swept into the air. ChemicalRecycling PETBottle Polyesterfibers

“Akin to global biogeochemical cycles, plastics now spiral around the globe,” said the study, led by researchers from Utah State University and Cornell University, and published in the journal Proceedings of the National Academy of Sciences.

That means much of the plastic that gets dumped in the sea and across the land is broken down and spat back out, posing potential risks for our ecosystems. And though there has been some progress with the creation of biodegradable polymers, the researchers warned microplastics “will continue to cycle through the earth’s systems.”

-Blue Toners & Colorants for Enhanced Recyclability of PET Packaging

Avient’s new ColorMatrix Optica blue toners and colorants formulated for addition to virgin and recycled PET for injection and extrusion processes.

New blue toners and colorants that are said to enhance the recyclability of PET packaging has been introduced by Avient Corp.. Formulated for addition to virgin PET and recycled PET (rPET), heat-stable ColorMatrix Optica blue toners work to correct and reduce the yellowing or color variation that typically occurs during the recycling process. ChemicalRecycling PETBottle Polyesterfibers

Variations in the aesthetic appearance of rPET, which can include yellowing and other color variations, as well as reduced processing efficiencies have been shown to be caused by multiple heat cycles, as the material is recovered and reused.

-Next-Generation Antifog Additive for Packaging and More

Avient’s new Cesa Nofog Plus performs in both hot and cold food packaging as well as agricultural and protective films.

A next-generation of antifog additive for food packaging applications has been launched by Avient Corp., spurred by the rapid growth in ready-to-eat foods, ready-to-cook foods, and food-delivery services. The new Cesa Nofog Plus additive is designed for both hot and cold packaging. ChemicalRecycling PETBottle Polyesterfibers

By reducing moisture accumulation, Cesa Nofog Plus reportedly helps prolong the shelf life of packaged foods. It can clear fogging immediately in hot conditions, and within minutes in cold conditions. Lids and protective films produced with this food contact-safe additive are also said to remain clear, so that consumers can observe the food quality.

-Biodegradable plastic launched in Nepal

Company says it is the first step in weaning consumers away from throwaway items

ANepali company has tried to address the growing problem of plastic pollution in Nepal by manufacturing biodegradable plastic products.

The Nepal government has tried and failed several times to impose a ban on single-use plastic, and the throwaway items have clogged drains and rivers across the country. Many of these take more than 500 years to decompose in dumping sites.

Now, Kathmandu-based Jain Trading Concern is introducing plastic bags and other items that degrade within three months of disposal. Although this does not reduce the use of plastic, environmentalists say it is a first step in reducing the amount of garbage on landfill sites, dumping sites and rivers. ChemicalRecycling PETBottle Polyesterfibers

ChemicalRecycling PETBottle Polyesterfibers