Chemicals BiobasedPolymers NylonRecycling 11-03-2021 - Arhive

Chemicals BiobasedPolymers NylonRecycling

Crude Oil Prices Trend

-Agr introduces novel solution for non-contact thickness measurement of non-PET containers

Agr International has introduced a novel, breakthrough method to measure thickness distribution in HDPE, PP, PE and similar containers.

An entire segment of containers is now able to be measured for thickness distribution with light-based optical technology. Prior to this development, many HDPE, PP, PE and similar containers that were highly coloured and had limited transparency, were not able to be measured using non-contact, light-based measurement techniques.

In the development of its new Gawis 4D dimensional and thickness measurement system, Agr Engineers were challenged to include the ability to measure thickness on a broader range of bottles including those constructed of HDPE and non-PET materials. To address thi, a novel ‘Integrated Method for Thickness Measurement’ was developed and implemented.

-DOMO and Tecnoplimeri develop cutting-edge household and electronics parts

DOMO and STS Tecnopolimeri have partnered to develop a leading range of household and electronic parts using DOMAMID FR 6G30V0E BK, a flame-retardant halogen-free PA6 product.

The growing demand for innovative products and metal replacement has led to the transformation of special materials for these sectors and increasingly strict fire codes and flammability requirements. The versality of PA6 and PA66 has been fundamental in many new developments. DOMO’s DOMAMID and TECHNYL ranges have become best-in-class flame-retardant solutions in the household and electronics markets.

Tecnopolimeri Owner Matteo Pigliapoco said: “DOMO Engineered Materials is our reference in the polyamide market and the recently homologated DOMAMID FR 6G30V0E is a melamine-based flame-retardant solution that has been proven to be first choice for several of our household and electronic cases such as a keyboards, covers, displays and command boxes, developed for the IoT generation.”

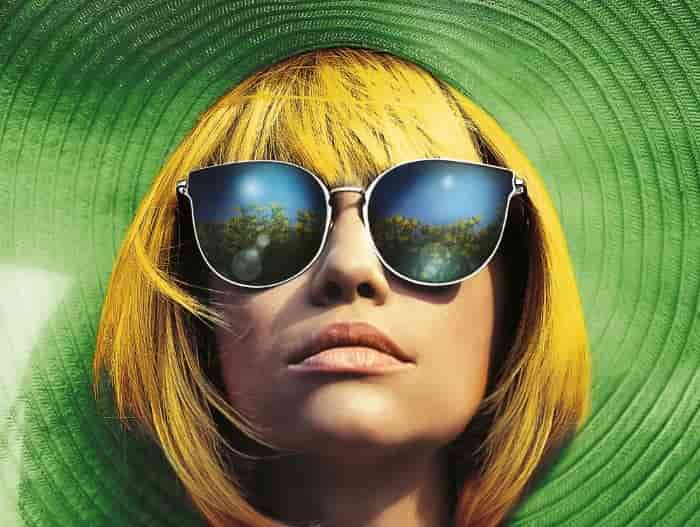

Evonik has added to its Trogamid transparent polyamide portfolio the new myCX eCO (“eliminate CO2”) grade obtained with partially biobased monomers (40%, from biomass attributed by mass balance) and produced entirely with renewable energy.

Thanks to these characteristics, it can boast an overall reduction of 50% of CO2 emissions compared to similar materials produced entirely from fossil raw materials.

High performance polyamide, with high micro crystalline purity, Trogamid myCX eCO has been formulated specifically for applications in optics (lenses and frames), where it guarantees – like conventional Trogamid grades – a transparency of more than 90%, good mechanical properties , resistance to stress cracking and breakage, making this material suitable for the production – for example – of goggles and visors for winter sports.

-Major Monforts Denim Customers Continue To Pioneer New Initiatives

Recycling their cotton waste has become one way these companies can do more with less, and at the recent Kingpins24 Flash online event, Sedef Uncu Aki, director of Orta, headquartered in Istanbul, Turkey, announced a new partnership with leading recycling operation Gama Recycle.

Traceable

“Through this local partnership we will supply the waste from our spinning mills and return around 3,000 tons of premium quality cotton back to them,” Aki said. “We have established a truly controlled and traceable system and partnering with a domestic recycling center is important because a lot the carbon emissions associated with recycling usually come from transportation.”

-Innovative Antibacterial Filter Developed by South Korean Researchers

The National Research Foundation of Korea announced on March 8 that Korea Institute of Industrial Technology senior researcher Choi Dong-yoon and Sejong University mechanical engineering professor Jung Jae-hee have proposed a filter for visible light-based airborne microbe sterilization.

At present, antibacterial filters using inorganic antibacterial substances such as silver, copper oxide and zinc oxide and those using natural organic substances such as chitosan are available for microbial sterilization. However, these require a direct microbial contact with a treated fiber surface and their performance tends to decline with time due to particular matter deposition.

In this regard, the research team aimed to devise a filter capable of affecting nearby microorganisms on the surface of the filter. To this end, it produced titanium dioxide-organic dye composite nanoparticles generating active oxygen in response to visible light and improved the surface in terms of moisture resistance and photochemical sterilization.

-Sustainable plastics manufacturing company expands in Houston and beyond

An under-the-radar company in Houston has ramped up its manufacturing capacity as it seeks to seize upon rising interest in sustainable plastics.

Houston-based Inhance Technologies, a sustainable manufacturer that transforms conventional plastics into high-performance materials, has a new site in St. Louis that comprises 75,000 square feet — more than double the size of the company’s old facility there. As a result of the expansion, Inhance Technologies’ headcount in St. Louis will rise to about 40. The size of the company’s entire workforce wasn’t available.

“The expansion in St. Louis is a great moment for the company and a sign of the organization’s ambition in sustainable solutions for plastics,” Patricia van Ee, chief commercial officer at Inhance Technologies, says in a release. “We know consumers are favoring more recyclable plastics, especially in packaging … .”

In January, the company promoted van Ee to her current role. She joined Inhance Technologies in 2019 as senior vice president of sales and marketing.

-‘Biodegradable’ plastic will soon be banned in Australia. That’s a big win for the environment

To start dealing with Australia’s mounting plastic crisis, the federal government last week launched its first National Plastics Plan.

The plan will fight plastic on various fronts, such as banning plastic on beaches, ending polystyrene packaging for takeaway containers, and phasing in microplastic filters in washing machines. But we’re particularly pleased to see a main form of biodegradable plastic will also be phased out.

Biodegradable plastic promises a plastic that breaks down into natural components when it’s no longer wanted for its original purpose. The idea of a plastic that literally disappears once in the ocean, littered on land or in landfill is tantalising — but also (at this stage) a pipe dream.

-Enegix unveils $5.4bn green hydrogen project in Brazil

Australia’s Enegix Energy reached an agreement with the Ceara state government to invest $5.4bn in a green hydrogen project that it says would be the largest of its kind in the world.

Enegix plans to use its proprietary technology to liquefy the green hydrogen, so it can be transported at ambient pressure and temperatures. The liquefied hydrogen can use the same infrastructure currently used to transport and store diesel, according to Marco Stacke, Enegix operations director.

The company has already contracted 3.4GW of wind and solar power from Brazilian renewable generator Enerwind to produce up to 600,000 t/yr of green hydrogen.

The company will develop the project, dubbed Base One, in the port of Pecem, which has the infrastructure to export the product as well as water needed for the process of electrolysis.

-Eastman’s Tritan Renew Finds Purchase in EMEA

Italy’s Snips will use the material composed of 50% recycled content to produce water bottles and food-storage containers, representing the first adoption of Tritan Renew in the Europe/Middle East/Africa (EMEA) market.

Italy-based Snips has partnered with Eastman to launch a line of water bottles and food-storage containers made with Tritan Renew copolyester. Renew is a durable, BPA-free material that contains 50% ISCC-certified recycled content produced via Eastman’s molecular recycling technology.

“Sustainability is at the core of our business,” said Snips owner Raffaele Piacenza. “Reusable housewares are a practical way to eliminate single-use plastic waste. We need to start thinking about new solutions to enjoy the advantages that plastic offers while reducing waste.”

Tritan Renew is made through Eastman’s Advanced Circular Recycling — also known as molecular recycling — which breaks down plastic waste into fundamental building blocks to be used again in manufacturing processes. By replacing traditional fossil-fuel feedstock with recycled content, Eastman said that it is helping to divert plastic waste from landfills, incinerators, and oceans. The process also produces fewer greenhouse gas emissions than manufacturing with fossil feedstock.

-Atlas Copco expands into industrial process cooling applications

Atlas Copco has extended its industrial portfolio to include process cooling equipment. The newly launched TCX 4-90A is Atlas Copco’s first process cooling chiller range, with plans to introduce more new products to the market in 2021 and extend the range to include higher cooling capacities.

“The addition of process cooling is the perfect complement to our compressed air and industrial gases portfolio,” said Alexander Pavlov, General Manager of Atlas Copco Compressors UK. He continued: “It means we can now deliver a broader product offering to our industrial customers, with the convenience of Atlas Copco service and connectivity.”

The TCX 4-90A Process Cooling Chiller range features a compact, all-in-one water chiller with an air-cooled condenser and integrated hydro module (onboard tank and pump solutions), with units available in a variety of sizes. TCX chillers are specially designed for cooling water (or a mixture of water and glycol) for a wide range of industrial segments including machine cooling, plastics, printing, food and beverage, medical and pharmaceutical.

Over the last year, Atlas Copco leveraged its more than 140 years of design experience to deliver an innovative chiller product with a wealth of service features and built-in connectivity. The innovative and familiar Elektronikon® Mk5 Touch controller comes standard on the 11 to 90 kW TCX models, putting control at the user’s fingertips.

Chemicals BiobasedPolymers NylonRecycling