Circular-plastics – Sustainable-Thermoplastic 11-05-2022 - Arhive

Circular-plastics – Sustainable-Thermoplastic

-Equipolymers and RITTEC announce cooperation

PET manufacturer Equipolymers continues to move towards the circular economy with new Rittec technology

- The aim is to meet the growing demand for rPET in food quality

- Significant increase in the proportion of recycled material in PET granules for food contact

- Fossil raw materials will continue to be replaced

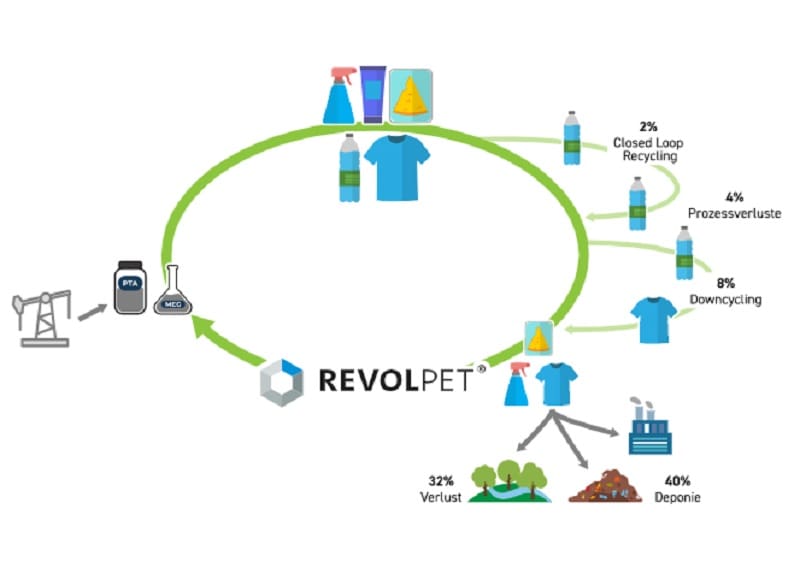

revolPET technology from Rittec provides the basis for recycled raw materials for PET in new product quality

PET manufacturer Equipolymers and technology startup Rittec Umwelttechnik announced their cooperation today in Schkopau. By developing and implementing Rittec’s revolPET process in Equipolymers’ PET production plant, the recyclate content in PET with food contact is to be significantly increased.

Mechanical PET recycling has successfully established itself in the European market over many years. However, the possible input materials for mechanical recycling processes are limited. For example, multilayer materials often used in the packaging sector or heavily coloured PET containers are very difficult to recycle. In addition, while PET is virtually unlimited and 100 percent recyclable, multiple mechanical recycling loops can compromise the optical properties of recycled PET.

Due to the insufficient availability of high-quality post-consumer PET, higher recycling volumes are difficult to achieve with existing technologies. In Germany, for example, the proportion of recyclates is currently only around 26 percent on average (source: IFEU study).

With revolPET, Rittec provides a technology solution to skip these boundaries. The use of this new chemical recycling solution, defined as a back-to-monomer process, enables the reprocessing of PET plastics in new product quality. The continuous recycling process can be used to close cycles of polyester plastics with high throughput rates. Circular-plastics – Sustainable-Thermoplastic

Substitution of virgin monomers within reach

Laboratory-scale polymerization tests have shown promising results. “Confirmed by the laboratory results, the replacement of virgin monomers is within reach for us,” says Olaf Hempel, Head of Development at Equipolymers. That is why the partners are striving for even more intensive cooperation in order to achieve their goals.

“Our revolPET technology can make an enormous contribution to the circular plastics economy,” comments Carsten Eichert, Rittec founder and managing director. “We want to prove that our basic PET components produced from post-consumer waste meet the standards for food contact.”

-bp supports circular plastics chain with Clean Planet Energy

bp signs 10-year offtake deal with Clean Planet Energy which aims to convert hard-to-recycle waste plastics into circular petrochemical feedstocks

bp has signed a 10-year offtake agreement with Clean Planet Energy, a UK-based company that is developing facilities to convert hard-to-recycle waste plastics into circular petrochemical feedstocks and also into ultra-low sulphur diesel (ULSD).

Clean Planet Energy designs and builds facilities – which they refer to as ecoPlants – that are expected to process plastics typically rejected by traditional recycling centres and so would otherwise be sent to landfill or incineration.

Under the new agreement bp will initially receive the output of Clean Planet Energy’s first facility, currently under construction in Teesside in the north-east of England.

The north-east facility is designed to have the capacity to process 20,000 tonnes a year of waste plastics into naphtha and ULSD. The naphtha can be utilised as feedstock into circular plastics value chains, which is aligned with bp’s aim of unlocking new sources of value through circularity, keeping products and materials in use for longer. Circular-plastics – Sustainable-Thermoplastic

Clean Planet Energy will provide bp with the opportunity to expand the relationship by offtaking products from its future plants beyond Teesside.

bp is already leading a series of major hydrogen and carbon capture and storage projects being developed in and around Teesside that will support decarbonisation of the region’s industries. Circular-plastics – Sustainable-Thermoplastic

Last November it unveiled plans for a new large-scale green hydrogen production facility that could deliver up to 500Mwe (megawatt electrical input) of hydrogen production by 2030 (click here).

Clean Planet Energy is currently in the process of developing 12 of its ecoPlants globally. From these facilities alone, the company aims to divert 250,000 tonnes of hard-to-recycle waste plastic annually from landfills and the environment, creating more than 700 green jobs in local communities. Clean Planet Energy plans to announce further ecoPlants in the UK, EU, South-East Asia and the Americas later this year.

-Step toward Circular Economy?

Catalytic deconstruction of PET with zirconium metal-organic framework

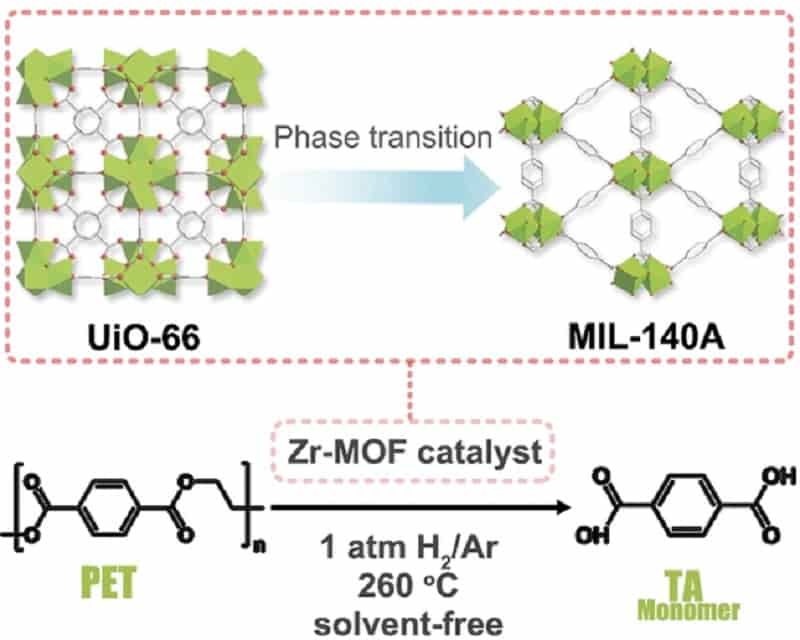

Polyethylene terephthalate (PET) is one of the most common plastics. Discarded PET most often ends up in landfills or in the environment because the rate of recycling remains low. In the journal Angewandte

Chemie, a research team has now reported a zirconium-based metal-organic framework material that catalyzes the degradation of PET into its monomers. These can then be reused to make high-value PET, allowing for development of a circular economy.

Almost 70 million tons of PET are produced annually. PET is processed to make products like fibers, drink bottles, and food packaging. Although PET can be melted down and reused, the high temperatures employed result in a lower quality of recycled products, limiting this strategy to only a few cycles. Chemical deconstruction of PET into its monomers would provide starting material for the renewed production of high-quality PET products but it requires large amounts of solvents and reagents, high pressures, and expensive separation of troublesome byproducts. Additives and dyed products could also make things difficult. The alternative would be a catalytic process. Circular-plastics – Sustainable-Thermoplastic

A team led by Omar K. Farha at Northwestern University in Evanston, USA has now reported a catalyst that breaks PET waste down at 260 °C into the building blocks terephthalic acid (TA) and mono-methyl terephthalate (MMT) in yields up to 98 %. The catalyst belongs to a class of materials known as metal-organic frameworks (MOFs), which are porous structures with metals at the nodes and organic molecules linking them.

The researchers chose to use UiO-66, a well-known zirconium-based MOF that can easily be produced on a large scale. UiO-66 consists of clusters containing six zirconium atoms as nodes, which are connected by six terephthalic acid molecules as linkers.

Extensive structural analyses showed that during deconstruction of PET, UiO-66 surprisingly rearranges into a different form with the same composition: MIL-140A, which is a framework of seven-coordinate zirconium oxide chains that are linked to six other chains by terephthalic acid bridges. This rearrangement only causes a slight decrease in the catalytic activity.

-New scenarios for 2022 Eurozone and UK PE growth as inflation and debt pressures build

The cost of living crisis in the developed world, and today we use the example of the Eurozone and the UK, is so severe that even single-use polyethylene (PE) demand is a risk.

Even before the Ukraine-Russia conflict, PE consumption was facing downward pressure as we moved from the pandemic to the endemic phase of coronavirus. Now, as interest rates rise at a time of worrying levels of public and private debt, we have to consider extent to which governments will be able to provide support for lower-paid workers who are under great pressure to cut back on their grocery spending.

We thus need scenarios for demand to enable the industry to better plan for an incredibly uncertain future. The blog has never known market analysis as complex as this:

The ICIS Supply & Demand Base Case growth for Eurozone and UK PE demand in 2022 over last year is 1%. I see this outcome as likely if the Eurozone and the UK can offset rocketing inflation through significant support for lower-paid workers. This will largely counteract the loss of tonnes resulting from the endemic phase of coronavirus. Circular-plastics – Sustainable-Thermoplastic

Downside 1 envisages limited wiggle room for extra fiscal spending on rising interest rates and further upward pressures on inflation. Here, consumption contracts by 4%.

The worst-case outcome, Downside 2, would see demand falling by 7% on full-blown stagflation and a debt crisis as much- higher interest rates make debt costs unserviceable. The worst-case outcome leaves demand around 900,000 tonnes lower than 2021 and a million tonnes lower than our Base Case for 2022.

Balanced against this should be the possibility that Eurozone and UK demand for imports will be higher than expected because of reduced purchases of Russian oil, naphtha and natural gas.

The decisions that PE exporters make from hereon in will be critical. Every tonne they produce and allocate to the region where the demand is, will of course make them money. And in a time of volatile and high feedstock costs, every tonne they don’t produce, when they correctly assess that the demand isn’t there in a particular market, will be important in preserving cashflow. Cash might be about to become king again, as in 2008-2009.

-Slowdown in US may affect China’s exports: Experts

The risk of the US economy slowing down and even nosediving into recession could add another layer of uncertainty to export growth and financial stability in China, underlining the necessity for China to strengthen its economy, say experts. Investors doubt whether the US Federal Reserve’s aggressive tightening can tame inflation without triggering a rapid decline in economic growth.

“We don’t think it (the recession risk) is a serious near-term concern,” Rob Subbaraman, head of global macro research at Nomura, was quoted as saying by an official Chinese media outlet, citing the cushion provided by high household savings, low unemployment rates and strong corporate balance sheets.

But the risk could increase going forward, Subbaraman said, as the financial services group forecasts that the cumulative probability of a US economic recession from now to the end of 2024 is fairly high at between 35 per cent and 40 per cent, with higher risk in the second half of 2023 and 2024.

He said US economic growth is likely to start slowing in the second half of this year due to factors like tightening monetary and fiscal policies and rising commodity prices that impair demand. Green-hydrogen – Food-packaging

He noted that a possible US slowdown could hurt Chinese exporters because they mostly sell goods to US consumers while consumption of goods could cool more sharply than the whole US economy as spending shifts from goods to services as the omicron wave fades.

“I think China is going to be negatively affected by the US slowdown and probably more so than you would realise just looking at aggregate US GDP growth,” Subbaraman said.

Signs have emerged that China’s export growth could face downside risks. An indicator of manufacturers’ new export orders dropped to 41.6 in April from 47.2 in March, pointing to a deeper contraction in export orders, said the purchasing managers index survey released by the National Bureau of Statistics.

-UBQ’s Sustainable Thermoplastic Incorporated in Hybrid Plastic-Metal Parts

Polymertal will use UBQ in lightweight metal-plated polypropylene parts with key metallic properties for automotive and other applications.

Tel Aviv–based UBQ Materials announced today a partnership with Polymertal, a developer of hybrid plastic-metal parts headquartered in Haifa, Israel. Polymertal will use UBQ’s sustainable thermoplastic, converted from unsorted plastic waste that would otherwise end up in landfills, in its new SPP-50XX material with metallic properties.

Polymertal’s SPP-50XX comprises 20% UBQ and 80% polypropylene. Metal plating composed of copper and nickel in varying thicknesses is placed on top of the plastic substrate, resulting in a lightweight part that exhibits key metallic properties, including durability, stiffness, heat resistance, and electromagnetic shielding, according to Polymertal. Applications include automotive, industrial, and consumer products. Circular-plastics – Sustainable-Thermoplastic

The inclusion of UBQ in the SPP-50XX base substrate reduces its carbon footprint. Compared with aluminum, for example, it reportedly achieves roughly a 50% reduction in CO2 emissions, as verified by World Watchers, a German organization that says it adapted the “proven WeightWatchers concept to climate protection.”

“Countless applications require materials that are lightweight, withstand high-temperature environments, and are thermally and electrically conductive,” said Polymertal CEO Ran Carmeli. “SPP-50XX exhibits all these features, and the presence of UBQ brings sustainability earlier in the supply chain, making it even easier for manufacturers to reduce the overall carbon footprint of their end products,” said Carmeli.

Circular-plastics – Sustainable-Thermoplastic