Ecofriendly r-PETResin Petrochemicals 08-06-2021 - Arhive

Ecofriendly r-PETResin Petrochemicals

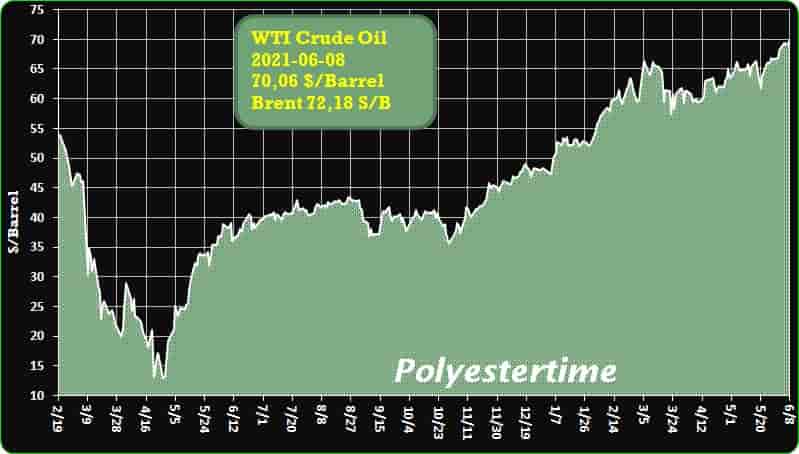

Crude Oil Prices Trend

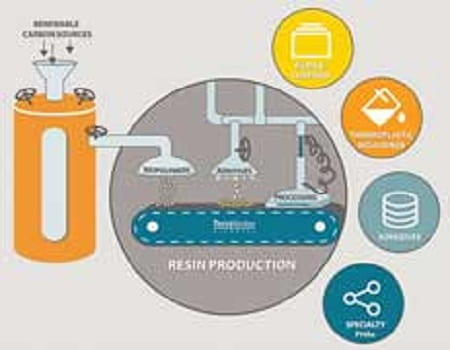

-Technip Energies with Agilyx to accelerate implementation of PS recycling technology

Technip Energies announced the initiation of an agreement with Agilyx Corporation, a wholly owned subsidiary of Agilyx AS, and pioneer in the advanced recycling of post-use plastics, said Hydrocarbonprocessing.

This collaboration aims to accelerate the implementation of Agilyx’s technology for the advanced recycling of post-use polystyrene. Under this agreement, Technip Energies will market and license the integrated technologies of Agilyx depolymerization and Technip Energies purification technology, leveraging the expertise, resources, and global presence of respective companies. The technology is ready and available for licensing.

Both companies bring strong, specialized experience to this offering: Agilyx contributes its deep experience in chemical recycling of post-use plastics, while Technip Energies has extensive experience in scaling-up technology which will increase the plastic recovery.

Stan Knez, Chief Technology Officer of Technip Energies, stated “We are delighted to scale-up this sustainable process to market with Agilyx, providing a reliable circular economy technology for a major plastic used widely throughout the world.”

-NOWOtex GmbH opts for Oerlikon Nonwoven meltblown technology

Oerlikon Nonwoven has commissioned a further high-performance meltblown system with ecuTEC+ electro-charging unit at NOWOtex GmbH & Co. KG in Eichenzell, Germany. Ecofriendly r-PETResin Petrochemicals

The Hesse-based company specializes in needled nonwovens and – with the new system – now also has meltblown nonwovens manufacturing capacities, allowing NOWOtex to expand its product portfolio. As of now, the company is producing polypropylene filter nonwovens, which are particularly suitable for protective masks. The coronavirus pandemic has not only increased demand for protective masks, the domestic manufacture of these products is now also be promoted and supported by the German Government.

Using the new meltblown system, NOWOtex will in future be manufacturing first-class filter nonwovens that can be used to produce up to 600 million operating room filter masks or 300 million highly-effective FFP2 masks per year. The system has been optimally equipped with the ecuTEC+ electrocharging unit for the production of mask nonwovens.

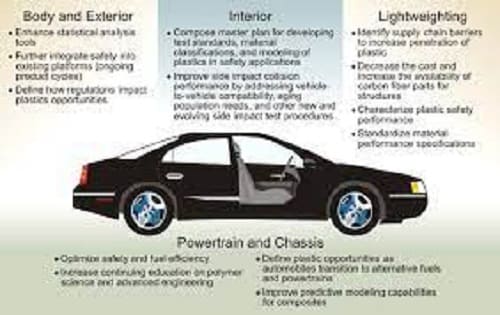

-Automotive Industry: Plastics hit the ground running in the EV evolution

In transportation, electric vehicles (EVs) are a key to countries around the world achieving climate goals. But the heavyweight EVs are turning to plastics and composites to reducing the weight and meeting sustainability goals, says Angelica Buan in this article. Ecofriendly r-PETResin Petrochemicals

EV sales on a high

This is to continue as battery advances lower EV costs

Major industries are recovering from the cataclysmic effects of the Covid-19 pandemic. But this is likely not the case with electric vehicles (EVs). Peddling to the concept of contributing to reductions in carbon emissions, sales have soared for EVs, even in the wake of the pandemic crisis.

-Packaging Sector: A zero-waste future with sustainable packaging

The food packaging sector is stacking up to growing market demand for sustainable solutions and the global carbon neutral goals, adds Angelica Buan in this report.

Sustainable packaging answers three essential issues of our time: human health and safety, climate change and conservation of natural resources. Moreover, packaging innovation has shifted focus from mainly the product to both the product and the packaging. Packaging has to be safe, durable, visually appealing and environmental friendly. Ecofriendly r-PETResin Petrochemicals

On the other hand, plastic packaging has been vilified due to its purported contribution to waste pollution and carbon emissions, as highlighted in a 2019 report by the Centre for International Environmental Law (CIEL). It suggests that petroleum-based plastic lifecycle accounts for a huge amount of greenhouse gas emissions (GHG). The methods of disposing common plastics, either by landfilling, incinerating, or recycling, also have carbon footprints. Carbon emissions from plastics in 2015 amounted to almost 1.8 billion tonnes of CO2. By 2050, it has projected the amount of GHG emissions from plastics to reach 56 gigatonnes.

-Donat chooses ALPLA’s rPET bottles

In cooperation with ALPLA, the Slovenian mineral water company Donat replaced its PET and glass packaging entirely with 100 per cent green rPET bottles. This cuts its carbon emissions by up to 90 per cent. Ecofriendly r-PETResin Petrochemicals

Under the motto of ‘green to green’, ALPLA initiated the use of 100 per cent green rPET bottles to replace the 100 per cent virgin-material PET and glass bottles conventionally used by the Slovenian mineral water company Donat. Donat’s decision to discontinue the use of virgin PET bottles and reusable glass packaging is resulting in an annual saving of around one million litres of drinking water and some 98,000 kilowatt-hours of electricity. 12,000 kilograms of cleaning product can be eliminated in this way too. This cuts its carbon emissions by up to 90 per cent.

”The “green to green” process for Donat is a prime example of how the circular economy can work if everyone all along the value chain pulls together.” – Christian Hude-Burian, Plant Manager PET Recycling Team.

-Sidel introduces Cermex EvoPack to anticipate customised retailing needs during production time

Changing consumer preferences, sustainability requirements, as well as the growing need for customisation of added-value packs and new selling or shipping units, are forcing manufacturers to adapt their production models and supply chains.

To meet the need for extreme case counts while still dealing with the standard high-production formats, Sidel is launching Cermex EvoPack, an Industry 4.0-enabled case-packing platform for shaped containers in wrap-around blanks, trays, and Shelf Ready Packaging (SRP). Ecofriendly r-PETResin Petrochemicals

Nowadays, consumers are becoming more demanding in their individual shopping needs, wanting to shop conveniently. Not only does the continuing e-commerce boom reflect this, but it can also be seen in the renaissance of smaller urban stores, with major retailers returning to the city centres to grant easy access to everyday necessities.

-Recyclable PE Mono-material Pump

Aptar Beauty + Home launches Future a recyclable PE mono-material pump designed for the beauty and personal care industry. Ecofriendly r-PETResin Petrochemicals

This content was submitted directly to this website by the supplier.

Christophe Marie, Product Sustainability Director, Aptar, explains, “The ideal situation for the complete value chain is to have mono-material packaging where the container, the closure or dispensing system is made from the same material family. This was the big challenge our innovation team overcame with the development of Future.”

A stand-out feature of the Future pump’s innovative design is an incorporated on/off locking system and a 360° degree actuator. Easy-to-use, this innovative locking system has a ring with an on/off actuation, which opens or locks the pump with an accompanying double-click sound. The 360° degree rotator allows to freely orient the actuator. Brands can choose from several different ring colors for customization. This modern take on closure design also renders Future compliant with the rigorous Amazon ISTA 6 protocol**. Designed for e-commerce, Future’s ISTA 6 compliance ensures that the pump withstands the risks associated with transport and distribution network pressures as well as necessitates less protective carton and paper packaging.

-More recycled plastics will not change polymers demand outlook – Dow CEO

Greater demand for recycled plastics will not change the overall demand outlook for polymers, the CEO at US chemicals major Dow said.

“End use polyethylene (PE) demand would still continue to grow [at] 1.3-1.5 times [to GDP]. It may mean you need less new [virgin] capacity coming on, but you have to blend more recycled material with the virgin content,” said Jim Fitterling during an investor call hosted by Bernstein. Ecofriendly r-PETResin Petrochemicals

“There are very few products where the end product is fully 100% post-consumer recycled (PCR) material to get the properties you need. You need to blend PCR with some virgin materials. And when you get into structural products like wood decking and other things, you have to blend in other fillers,” he added.

Dow aims to increase PCR content in its products and also design fully recyclable packaging.

In February, the company signed a memorandum of understanding (MoU) with India-based Lucro Plastecycle to develop and launch PE films using PCR plastics in India.

Dow is also advancing chemical recycling of plastics through partnerships with Fuenix and Mura Technology which would supply feedstocks for Dow’s crackers.

-Bottled water maker CG Roxane opens second PET recycling plant

CG Roxane LLC, which owns the Crystal Geyser Alpine Spring bottled water brand, said June 2 it is opening a PET recycling facility in Benton, Tenn., as part of its plan to have 50 percent recycled content in its bottles in the U.S.

It’s the second such facility for the Novato, Calif.-based company, which opened a recycling plant in San Bernardino, Calif., in 2019.

The 60,000-square-foot Tennessee plant, which will be in its existing Benton factory, will open in 2022. Ecofriendly r-PETResin Petrochemicals

CG Roxane said each facility will have the capacity to reprocess 35 million pounds of recycled PET annually, saving 285,000 gallons of crude oil and 210 million pounds of carbon dioxide emissions annually compared with virgin resin.

-SIBUR to explore role in Kazakhstan PP, PE projects

SIBUR has signed a framework agreement with Kazakhstan sovereign wealth fund Samruk-Kazyna and state oil and gas company KazMunayGas that could allow the firm take a role in petrochemicals projects set to add nearly 2m tonnes/year of polymer capacity in the country. Ecofriendly r-PETResin Petrochemicals

SIBUR is considering taking a role in an ongoing project involving the construction of a gas chemical complex to produce 500,000 tonnes/year of polypropylene (PP).

The company is also mulling a role in a future project to build a 1.25m tonne/year polyethylene (PE) facility in the country.

Raw materials for the projects would be sourced by the partners in the proposed joint venture. SIBUR’s decision on both projects is expected by the end of 2021.

“Our partners have extensive experience in constructing and operating large facilities in the oil and gas production, transportation and processing and will in turn be able to support the projects with the necessary raw materials and infrastructure within the special economic zone,” said SIBUR CEO Dmitry Konov.

Ecofriendly r-PETResin Petrochemicals