Graphene – Additives – Recycling 09-09-2022 - Arhive

Graphene – Additives – Recycling

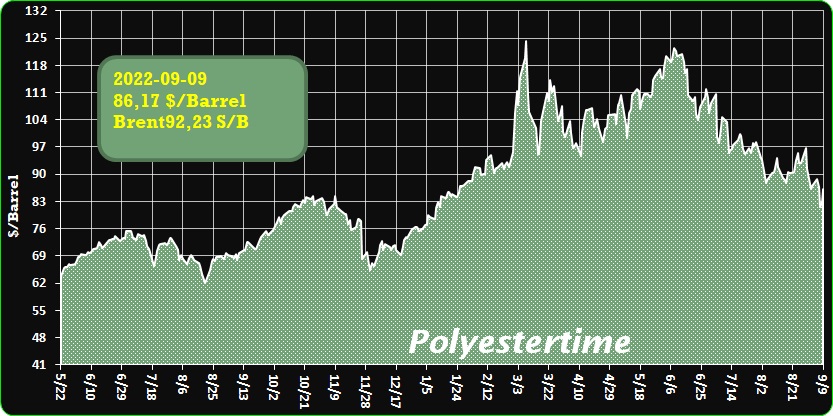

Crude Oil Prices Trend

-Over 75% of plastic in Great Pacific Garbage Patch originates from fishing

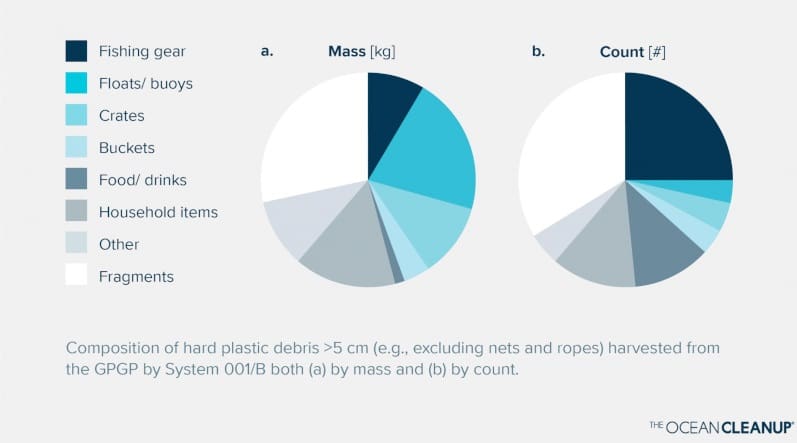

The non-profit organisation Ocean Cleanup has published new research in the journal Scientific Reports showing that the Great Pacific Garbage Patch (GPGP) is largely composed of fishing-related plastic waste, with 75% to 86% of all plastic waste in the GPGP identified as coming from offshore fishing activity.

Analysis of over 6,000 plastic objects also found that major industrialised fishing nations (including the United States, China, Japan and Korea) are the principal producers of the fishing waste found in the GPGP, an area three times the size of France and the world’s largest accumulation of floating ocean plastic.

At a global level, emissions from rivers remain by far the largest source of plastic pollution into the oceans. However, specifically for the GPGP, this is not the case, and this confirms that the GPGP requires an approach not only involving cleanup and interception; this ‘other source’ of GPGP pollution – i.e., plastic originating from fishing activities – must also be tackled.

The Ocean Cleanup conducted the research on plastic objects and fragments captured in the GPGP during cleaning operations of its System 001/B solution in 2019. Researchers painstakingly investigated the origins, sources and ages of these objects to create the most comprehensive picture of GPGP plastic so far presented, building on The Ocean Cleanup’s previous research, conducted in 2018.

“This research significantly expands our understanding of the Great Pacific Garbage Patch,’ said Matthias Egger, Ocean Plastic Researcher at The Ocean Cleanup. ‘In order to solve this problem we need to understand it, and identifying the origins of GPGP plastic is essential to our cleanup efforts, and the efforts of other organisations, to reduce this other source of pollution.” Graphene – Additives – Recycling

“To stop the inflow of plastic into our oceans, addressing river emissions – the largest source – must remain core priority” said Boyan Slat, founder and CEO of The Ocean Cleanup.

-Haydale’s supplies graphene to NeoEnpla for use in food packaging

Haydale has started to supply South Korean plastics developer NeoEnpla with functionalized graphene nano-platelets (GNPs) for use in food packaging. Functionalized using Haydale’s patented HDPlas® technology, the GNP-enhanced thermoplastic has been used to manufacture an initial sample range of food storage zipper bags and biodegradable plastic bags.

LLDPE and LDPE (low density polyethylene) are widely used in food packaging and are ideal for food storage due to their high resistance to moisture, tearing and chemicals. The graphene-enhanced zipper bags have reportedly shown an increase in tensile strength of 31% compared to non-graphene LLDPE (linear low-density polyethylene) zipper bags. In addition, the increased mechanical strength of the graphene zipper bags allows light weighting of the plastic, reducing the film thickness from 90µm to 60µm per bag.

Since food packaging primarily acts as a barrier to moisture and gases (including contaminants) that ordinarily lead to a reduction in the shelf-life of food, the new graphene-enhanced food storage bags can keep the food fresher for longer thanks to the anti-bacterial, UV and barrier properties of functionalized graphene. The graphene-composites polymer bags demonstrated their own oxygen blocking effect keeping food such as bread, cake and rice containing carbohydrates fresher for longer compared to non-graphene bags. Graphene – Additives – Recycling

Plastic packaging is necessary to maintain the shelf life of fresh food items, reducing food waste by spoilage before use. By ensuring barrier performance is delivered in products that can be recycled or composted, there is the potential for a more sustainable approach to the challenges often faced by producing recyclable materials.

With the increasing demand to reduce single use plastics and increase recycling rates, getting the performance characteristics demanded by the industry is a challenge. To address this, Haydale reported that both recyclable LLDPE and LDPE were evaluated in addition to PBAT (Polybutylene Adipate Terephthalate), a biodegradable polymer that is already seeing increasing demand for its biodegradable properties.

The new biodegradable bags contain a blend of PLA (Polylactic Acid) and PBAT, and enhanced with GNPs, offer increased strength without affecting the compostability of the films.

-BRICS expansion – Matter of time

is inevitable in light of developed Matter of time – Opinion – Chinadaily.com.cncountries’ unwillingness to give developing countries greater say in global governance, but will take efforts Graphene – Additives – Recycling

Although BRICS has engaged several other nations under the rubric of “BRICS Plus “and “BRICS Outreach” summits, the group has remained cautious about adding new members.

Lately, however, expanding its membership has become a subject of discussion at the BRICS summits, especially those of 2013, 2017 and 2022 when China was the chair, as it is noticeably in favor of additional members. Russia and South Africa have also become increasingly agreeable though they believe no single nation should be allowed to decide on the new entrants. Brazil and India, on the other hand, are still cautious.

Nevertheless the die has been cast and expansion is bound to happen sooner rather than later. The Beijing Declaration from their 2022 summit, for instance, agreed on “promoting discussions … on the expansion process … to clarify the guiding principles, standards, criteria and procedures” in order to expand cooperation with other emerging markets and developing countries.

This sentiment for expansion was also visible in their 2021″terms of reference” for their Sherpas.

Five new nations could be joining BRICS in 2023 during the presidency of South Africa, which joined the original group of four BRIC countries in 2010.Applications from Iran and Argentina are already under consideration while Saudi Arabia, Turkiye and Egypt have begun the process of applying for membership.

Turkiye, in particular, is keen on fast forwarding the application process. In addition, Algeria, Bangladesh, Indonesia, Kazakhstan, Mexico, Nigeria, Pakistan, Sudan, Syria, the United Arab Emirates and Venezuela have also expressed interest in joining. Several of them participated in the May 2022 “BRICS Plus” foreign ministers’ meeting convened by China. Graphene – Additives – Recycling

Among the arguments in favor of expansion, BRICS remains under-represented in global financial governance. Collectively the five members account for more than 50 percent of global growth, 40 percent of global currency reserves, 25 percent of global GDP and 16 percent of world trade, and yet, they hold no more than 15 percent of the voting rights in both the World Bank and the International Monetary Fund.

BRICS’ advocating for free, fair and equitable global commerce has made it the flag bearer of the aspirations of the Global South that believes its interests are not adequately protected under the existing global financial governance system. The BRICS’ GDP is set to surpass the G7 economies’ GDP by 2032 if not earlier.

However, the criteria for expansion may not be GDP or market size. The inclusion of South Africa was based on it being the gateway of BRIC into Africa, the next center of growth, and the inclusion of a country from the African continent would make BRICS global.

-BASF offers product carbon footprints to its plastic additives customers through myPlasticAdditives

BASF now offers its plastic additives customers product carbon footprints (PCFs) for several antioxidants and light stabilizers as a premium service within the VALERAS™ portfolio. By improving CO2 transparency in the value chain, BASF will support customers in reaching their greenhouse gas emission reduction targets. Using its proprietary digital solution and validated calculations, BASF can now provide cradle-to-gate PCFs. A cradle-to-gate PCF comprises the total greenhouse gas emissions that occur from the extraction of resources through the manufacturing of precursors to the making of the final chemical product itself. Graphene – Additives – Recycling

«BASF aims to achieve net zero emissions by 2050. At the same time, we are continuously working with our customers to help them reach their climate targets. With this digital solution, we create greater transparency with high quality PCFs to enable them to satisfy their customer requests and validate sustainability claims for creating low-carbon plastics,» said Dr. Achim Sties, Senior Vice President, Performance Chemicals Europe, BASF. «We are committed to increasing the sustainability of plastics along the entire polymer value chain and are taking the next step as the first additives producer to offer a broad range of PCFs to the market.»

The PCFs will be available as a premium service through a new online customer portal named myPlasticAdditives. It is a convenient and easy-to-use digital solution to access on demand a broad library of regulatory, sustainability and technical information. This online portal will help customers drive efficiency and improve business processes with BASF support at their fingertips. Registration for an account is available at myPlasticAdditives.basf.com.

The first wave of available calculations includes products in the Irganox®, Tinuvin® and Chimassorb® portfolios; further products will follow. PCFs for plastic additives are part of the VALERAS™ portfolio. Providing customers with new valuable sustainability information allows them to understand the extent to which BASF’s plastic additives materials contribute to the carbon footprint of their final products. With VALERAS, BASF is committed to increasing the sustainability of plastics along the entire polymer value chain with innovative solutions and offerings from its plastic additives business.

-GrapheneUP launches next-gen graphene-enhanced formulations for textile industry

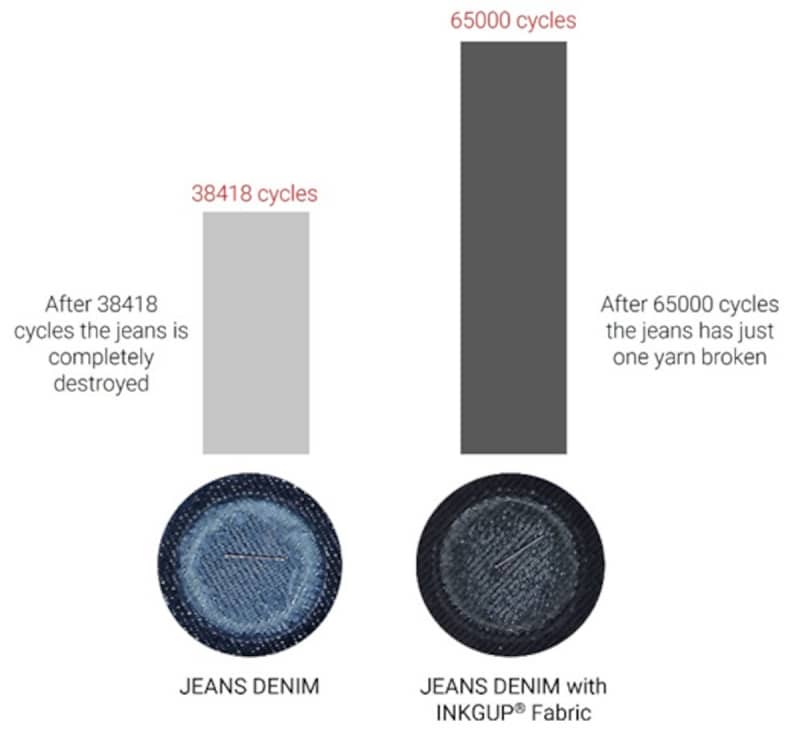

Population growth and improved living standards require solutions for textiles with new functions to meet changing needs. Wherever they are used, graphene-based smart textiles provide added value in terms of improved performance or comfort. GrapheneUP®, a leading graphene company with the largest production of few-layer graphene in Europe, has developed and introduced into the market new graphene-based products for textile industry: INKGUP® Fabric and PRINTGUP®. Graphene – Additives – Recycling

INKGUP® Fabric is graphene-based coating formulation for textile industry produced with few-layer graphene GUP®, designed to provide superior finishing properties. This formulation has been certified antiviral (ISO 18184:2019) also for SARS-CoV-2, antistatic and with excellent abrasion resistance and thermal regulation properties.

Several properties of textiles are improved using the formulations developed with GrapheneUP®, in particular the thermal regulation, abrasion resistance, EMI shielding, UV protection, excellent electrical conductivity, antibacterial and antiviral properties.

-S Korea to hold talks with US over Inflation Reduction Act

South Korean trade minister Ahn Duk-geun is currently in the US to discuss the Inflation Reduction Act (IRA) of the US, which restricts trade freedom given under the US-Korea free trade agreement (KORUS FTA). South Korea, being a friendly partner country has more dependency on the US which is also an important market for Korean textile exports.

South Korea believes that the US law (IRA) violates KORUS FTA, and hence the talks are being considered crucial for the two countries and their trade relation.

The IRA was signed recently, offering tax rebate to each buyer of an electric vehicle (EV) assembled in North America. The rebate will not be available for all EVs imported from outside the North American region, including Europe and south Korea.

The US is an important market for Korean textile exports also. According to Fibre2Fashion’s market insight tool TexPro, the US is among the top four destinations for South Korean garment exports. South Korea’s garment exports totalled $1.962 billion in 2021. The US was the fourth largest importer of Korean clothing with a share of 12.49 per cent. Graphene – Additives – Recycling

As per TexPro, South Korean garment exports to the US increased sharply after a fall during the pandemic. The exports dropped to $174.771 million during 2020, from $215.996 million of the previous year.

-MORE Platform will contribute to the PRecycling Project

The European Plastics Converters (EuPC) is one of the seventeen partners of the European project “Plastics Recycling from and for Home Appliances, Toys and Textile (PRecycling)”, funded by the Horizon Europe research and innovation program.

Its objective is to produce high-quality recyclates from plastic waste streams by developing an easy-to-use methodology for sorting, sampling, tracing, recycling techniques, and analysis procedures of both plastic waste streams and recyclates.

The PRecycling will develop new technologies and methods to promote the circularity of plastics, aiming to overcome obstacles from current technologies by designing materials and formulations from recyclable plastic resources, ensuring their quality and safe use, verifying the recyclate content, and at the same time producing new added-value products, both in the closed and open loop. Graphene – Additives – Recycling

The consortium will utilise the MORE Platform when developing tracking, and tracing methodologies that will allow full digitalisation of the recyclates management, through the development of digital traceability systems and complete digital information management via blockchain technologies. In order to achieve these ambitious goals, project partners like BASF, Circularise, Fraunhofer, EuPC, AIMEN, NTUA, AIJU and IRES, will cooperate to deliver novel systems that will be used in the industry.

Among other deliverables, the project will develop and demonstrate standard, robust and easy-to-use sampling and analysis procedures to ensure consistent recyclates quality and safe products. In addition, it will also develop methods for traceability of recyclates to allow the identification of the origin of recycled materials via digital information management, through marking technologies and blockchain approaches.

The Fibre Bottle is designed for dry goods, and should enable brands producing goods such as vitamins, supplements, dry foods, home care and horticultural products to remove 270m single-use plastic bottles or pouches from shelves per year.

The Scottish innovator said the Fibre Bottle is made from 100% natural matter, recycled cardboard and water, and is biodegradable and compostable, in comparison to its counterpart plastic that will leave a 200-1000 year legacy in landfills.

The Fibre Bottle should be shelf-ready at scale, with Cullen already producing hundreds of millions of moulded fibre bottles for the healthcare sector across 34 countries globally.

Whereas the Fibre Bottle is launched in one design iteration, thanks to Cullen’s bespoke service, the innovator can create any size or colour or any packaging design wanted by Fast-Moving Consumer Goods (FMCG) brands. Graphene – Additives – Recycling

Within one month, the firm’s in-house design, engineering and manufacturing teams should be able to create a bespoke moulded fibre alternative for most plastic packaging, of which the Fibre Bottle is the latest example.

Cullen said that, upon approval, the sustainable units can be made affordably and quickly at a commercial scale, so that more brands than ever will be able to seamlessly replace plastic with its sustainable alternatives.

Graphene – Additives – Recycling