Indorama-IVL – Chemical recycling 17-03-2023 - Arhive

Indorama-IVL – Chemical recycling

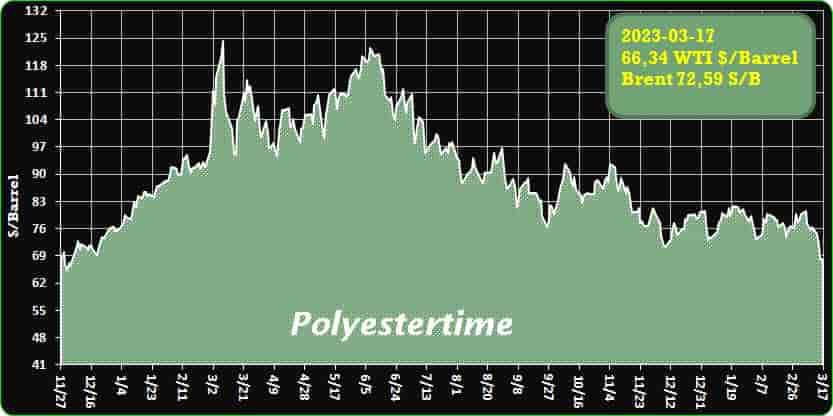

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Piovan Group takes over selected assets of Protec Polymer processing gmbh

Piovan Group’s strengthening continues with further expansion into Germany, Europe’s reference market for plastics by supporting German ProTec’s systems – ensuring continuity and qualified assistance to some of the company’s customers.

Piovan Group acquires a selection of assets of German competitor Protec Polymer Processing GmbH (“Protec”), an international supplier of systems for the plastics industry, currently in receivership.

The transaction involves certain assets previously belonging to material handling, dosing and Recycling divisions – markets where the Piovan Group itself operates and is world leader in the production of systems for automating production processes with plastic, recycled plastic and bio-plastic materials. Indorama-IVL – Chemical recycling

The transaction will take place through the controlled FDM with the triple purpose of: increasing the Service/post-sale activities, offering customers upgrades and retrofits of old Protec systems with new Piovan Group solutions, and supporting joint customers in the difficult situation caused by the bankruptcy proceedings of ProTec Polymer Processing GmbH.

Piovan Group, which is actively engaged in the development of products and solutions dedicated to the recycling and circular economy supply chain, going forward will also supply Protec’s solutions in the recycling field, such as plastic regeneration and crystallization. Indorama-IVL – Chemical recycling

In line with the group strategy the transaction strengthens the Piovan Group’s presence in the German market and in the key strategic segment of after sales services.

“Protec, previously Somos, is among the oldest European companies operating in automation for plastic and recycle plastic industry with a large installed base of unique solutions and a well-established customer base. – says Filippo Zuppichin, CEO of Piovan Group – It is a great honour and responsibility for Piovan Group and FDM to continue such an important tradition and offer their customers the possibility of enjoying such a long technological partnership.”

“For FDM it is an important step to further expand and establish the service area. We are pleased to be able to offer all customers the usual service in the field of service and spare parts supply” – says Guido Faust, General Manager of FDM. Indorama-IVL – Chemical recycling

-Brussels blocks the decree against plastic in fruit and vegetables

Suspension of at least twelve months of the French provision because the matter is subject to the new Regulation on packaging and packaging waste.

After the French Council of State, which at the end of last year had suspended the application of the ban, which came into force on 1 January 2022, on the sale of fresh fruit and vegetables packed in plastic packaging, weighing less than a kilo and a half (read the article), the European Commission also intervenes on the matter, to which the measure was notified as usual (see procedure). Indorama-IVL – Chemical recycling

To the satisfaction of the Plastalliance association, which represents the interests of the plastics industry in France, Brussels has suspended the application of the provision for at least twelve months, given that the matter is being regulated at Community level. Indeed, the Commission is working on a new regulation on packaging and packaging waste, which contains specific provisions on the packaging of fruit and vegetables.

fruit and vegetable tray photo: Ilip Pursuant to article 6, paragraph 4, of the directive of 9 September 2015 containing an information procedure on technical regulations and rules relating to information society services: “Member States postpone the adoption of a draft technical regulation twelve months from the date of receipt by the Commission of the notification referred to in Article 5(1) of this Directive, if, within three months of that date, the Commission notifies that the draft technical regulation concerns a matter governed by a proposal for a directive, regulation or decision submitted to the European Parliament and to the Council in accordance with Article 288 of the Treaty on the Functioning of the European Union”. Indorama-IVL – Chemical recycling

“It is time for the French government to admit that all the French provisions deriving from the Egalim law, the AGEC law, the climate and resilience standards and the related decrees concerning single-use plastic packaging will be rendered ineffective – comments Plastalliance – unless they are exactly aligned with the provisions of the future European Regulation which will have to be applied, without further over-regulation, to national legislation”.

-Alpla and Inden pharma form joint venture

ALPLA is expanding its presence in the global market for pharmaceutical packaging by establishing a joint venture with Inden Pharma

The ALPLA Group with its division ALPLApharma and the Spanish packaging company Inden Pharma are strengthening their footprint in the pharmaceutical market by establishing a joint venture.

ALPLApharma is bringing production sites in Greece and Poland into the cooperation, complemented by Inden Pharma’s two facilities in Spain and an additional one the two companies are jointly building in Germany. The companies are planning a combined annual production of around 800 million pharmaceutical packaging products in 2023 and a three-fold increase in the next five years. Indorama-IVL – Chemical recycling

ALPLA is expanding its presence in the global market for pharmaceutical packaging by establishing a joint venture with Inden Pharma. ALPLA, the international specialist in plastic packaging and recycling, and the internationally renowned Spanish pharmaceutical packaging company Inden Pharma, are starting a long-term partnership for the certified production of bottles, containers and closures in clean rooms, starting in March.

The joint venture includes two ALPLApharma production sites in Greece (Koropi) and Poland (Żyrardów) and the two Spanish plants of Inden Pharma in Ibi, north of Alicante, as well as a jointly built fifth plant in Germany (Markdorf), which is scheduled to start production in June.

“We combine global presence with high standards and technology leadership. Together, we are even closer to our customers and are expanding our range of high-quality, cost-effective and sustainable packaging solutions,” says Philipp Lehner, CEO of ALPLA.

Since entering the fast-growing market of pharmaceutical packaging in 2016, ALPLA has continuously expanded into new countries, technologies and product categories. Inden Pharma is also focused on strong growth. In the last four years, the company has tripled its sales to reach 30.5 million euros in 2022. Indorama-IVL – Chemical recycling

-Indorama Ventures outlines plan for disciplined, sustainable growth

Indorama Ventures Public Company Limited (IVL), a global sustainable chemical producer, today outlined its business strategy at its 2023 Capital Markets Day in Bangkok, including enhancing competitiveness and applying a disciplined and sustainable approach to new opportunities as demand for the company’s products continues to grow globally, said the company.

Since 2019 – a three-year period that included unprecedented pandemic-related disruptions – Indorama Ventures’ revenue grew 65% to a record USD18.7 billion in FY2022, while EBITDA rose 160% to USD2.4 billion. The company forecast continued high demand for its diversified, global portfolio of products – more than 70% of which are used in daily consumer necessities that are resistant to economic downturns, including in packaging, clothes, tires, baby diapers, and chemicals used in shampoos.

Mr. Aloke Lohia, Indorama Ventures Group CEO, said “The company is developing and empowering the next generation of leaders with a ‘growth mindset’ as a cornerstone of a program to enhance competitiveness and create value through disciplined and sustainable growth.” Indorama-IVL – Chemical recycling

“We are, and always will be a growth company, and we are embedding this entrepreneurial mindset into the next generation of leaders who can build agile, fast, precise and innovative businesses that can deliver value in an increasingly volatile world,” Mr Lohia said.

-Sorting and recycling plastic is notoriously hard—but this AI could help

Barely 5 percent of all plastic intended for recycling facilities ends up in a new product.

It’s one of society’s worst kept secrets: Most plastic thrown into the blue and green bins doesn’t actually get recycled. In fact, studies show that barely 5 percent of all plastic intended for recycling facilities makes it through the process and back into new products. There are a number of factors that contribute to this strikingly low number—including contaminated materials, water requirements, and discarded waste—but it’s a problem made even worse by the fact that the average American’s plastic waste consumption has increased 263 percent since 1980. Indorama-IVL – Chemical recycling

It’s a serious situation that needs a solution sooner than later, and researchers are on the hunt for an efficient and effective fix. As detailed in a paper published with Frontiers in Sustainability, a team at University College London has developed a new machine learning model capable of isolating compostable and biodegradable plastics from conventional varieties to improve recycling efficiency and accuracy.

Most of today’s plastics fall within a handful of categories possessing different chemical makeups—polyethylene (PET) and polypropylene (PP) compose the majority of drinking bottles and food containers, while low-density polyethylene (LDPE) can be found in items like plastic bags and packages. Meanwhile, compostable options featuring polylactic acid (P

Sorting and recycling plastic is notoriously hard—but this AI could help

Barely 5 percent of all plastic intended for recycling facilities ends up in a new product.

It’s one of society’s worst kept secrets: Most plastic thrown into the blue and green bins doesn’t actually get recycled. In fact, studies show that barely 5 percent of all plastic intended for recycling facilities makes it through the process and back into new products. There are a number of factors that contribute to this strikingly low number—including contaminated materials, water requirements, and discarded waste—but it’s a problem made even worse by the fact that the average American’s plastic waste consumption has increased 263 percent since 1980. Indorama-IVL – Chemical recycling

It’s a serious situation that needs a solution sooner than later, and researchers are on the hunt for an efficient and effective fix. As detailed in a paper published with Frontiers in Sustainability, a team at University College London has developed a new machine learning model capable of isolating compostable and biodegradable plastics from conventional varieties to improve recycling efficiency and accuracy.

Most of today’s plastics fall within a handful of categories possessing different chemical makeups—polyethylene (PET) and polypropylene (PP) compose the majority of drinking bottles and food containers, while low-density polyethylene (LDPE) can be found in items like plastic bags and packages. Meanwhile, compostable options featuring polylactic acid (PLA) and polybutylene adipate terephthalate (PBAT) are generally in tea bags, magazine wrappings, and coffee cup lids. Finally, biomass-derived plastics from palm-leaf and sugar cane are often used in other packaging needs.

LA) and polybutylene adipate terephthalate (PBAT) are generally in tea bags, magazine wrappings, and coffee cup lids. Finally, biomass-derived plastics from palm-leaf and sugar cane are often used in other packaging needs. Indorama-IVL – Chemical recycling

-Enel S p A : X and MIDAC join forces to develop a sustainable lithium battery supply chain in Italy

This initiative, implemented in partnership with other Italian and European companies and research institutes, is part of the European IPCEI (Important Project of Common European Interest) project “European Battery Innovation”

The goal is to help develop a sustainable and circular European supply chain by building a lithium battery recycling plant

Rome, March 15th, 2023 – Enel X and MIDAC are engaging in R&D activities to build Italy’s first major recycling plant for lithium batteries used in electric vehicles, industrial systems, and stationary systems. Indorama-IVL – Chemical recycling

This initiative, implemented in partnership with other Italian and European companies and research institutes, including ENEA (Italian National Agency for New Technologies, Energy and Sustainable Economic Development), is part of the European IPCEI batteries project. The goal is to help develop a European lithium battery supply chain that is both sustainable and based on a circular approach. It is estimated that, in Europe, a total of around 200,000 tons of lithium batteries will have to be recycled by 2030. Therefore, this project will help make the energy transition more sustainable.

“We are proud to have partnered for this challenging and strategic project aimed at establishing a European battery supply chain,” says Francesco Venturini, CEO of Enel X. “Thanks to this project we will be able to open up new markets and new growth opportunities for companies by combining efficiency, sustainability and innovation, making it possible for Europe to achieve a critically important goal, which is to become more independent when it comes to sourcing raw materials.” Indorama-IVL – Chemical recycling

“We are currently developing and investing in state-of-the-art recycling processes so that we can support the Italian and European lithium battery supply chain and actively contribute to the energy transition,” says Filippo Girardi, President of MIDAC. “We will start with recycling and we will then move on to cells. Our plants will be located in Italy so that we can strengthen our presence in the Italian battery industry, providing employment opportunities and promoting growth all over the country.”

-TotalEnergies: forging links for a chemical recycling value chain

Grandpuits zero-crude platform takes shape

A new commercial agreement signed by TotalEnergies and Paprec, a leading French independent plastics recycler, is designed to put in place the first links in a new value chain being developed in France for the chemical recycling of plastic film wastes.

In September 2020, TotalEnergies announced plans to invest more than €500 million to convert its Grandpuits refinery into a zero-crude platform. The company has since entered into numerous partnerships, designed to see the construction of facilities for (aviation) biofuels and bioplastics production, as well as plastic waste recycling, all powered by solar energy. Indorama-IVL – Chemical recycling

The project is part of TotalEnergies strategy to get to net-zero emissions by 2050.

The plastics recycling plant is being built by TotalEnergies (60%) in partnership with advanced recycling company Plastic Energy (40%) and will be based on the pyrolysis technology developed by Plastic Energy. It will have a capacity to handle 15,000 tons of waste per year and is scheduled to be operational in 2024.

The present deal is aimed at securing the feedstock supply for the plant. Under the terms of the agreement, Citeo, the French household packaging compliance scheme, will supply a stream of flexible plastic waste sorted from post-consumer packaging to the Paprec Plastiques 80 plant in Amiens. Here, a sorting and preparation line will be built for the waste, which will then be converted into feedstock for the production of virgin-quality recycled plastics. Indorama-IVL – Chemical recycling

“This long-term agreement is a major milestone for our advanced recycling plant at Grandpuits, as it guarantees a supply of waste of French-origin,” said Valérie Goff, Senior Vice President Renewable Fuels & Chemicals at TotalEnergies. “It is a tangible example of TotalEnergies’ commitment to developing a circular economy for plastics and fully contributes to our ambition of producing 30% circular polymers by 2030.”