Ocean-Plastic-Recycling – Bioplastics 15-07-2022 - Arhive

Ocean-Plastic-Recycling – Bioplastics

Crude Oil Prices Trend

-Floatable pressure-sensitive label from CCL endorsed by EPBP and APR

CCL Label, a leading converter of pressure sensitive and extruded film materials for decorative, functional and information labels, has unveiled a new generation of their EcoStream labels that support the recycling of PET bottles. They are made from floating low-density polyolefin material that are claimed to separate easily from the heavier PET flakes in the sink/float process step at the sorter and recycler – which results in the yield of clean PET flakes that can be recycled back into new bottles.

The European PET Bottle Platform (EPBP) and the Association of Plastic Recyclers (APR) in the United States both officially endorsed the new label generation.

The EcoStream SP (Shear Performance) clear and opaque white pressure sensitive label is a further development of the existing EcoStream version, that has been successfully supplied to the international beverage market for many years.

Freshly blown and immediately labelled bottles can induce folds or bubbles on regular labels. EcoStream SP pressure sensitive labels are developed to keep perfect labelling through flexible properties in particular suitable on post-shrinking PET bottles.

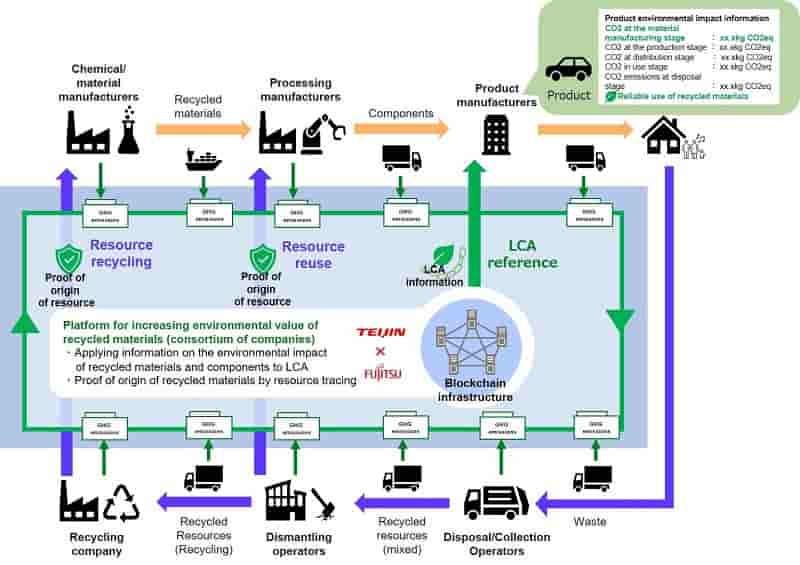

eijin Limited (hereinafter Teijin) and Fujitsu Limited today launched a joint project to realize a blockchain-based commercial platform for enhancing the environmental value of recycled materials for manufacturers, said the company.

The collaboration will promote environmentally conscious design(1) by leveraging Teijin’s Life Cycle Assessment (LCA) Calculation Method for measuring the environmental impact of manufacturing processes across the value chain, as well as Fujitsu’s blockchain technology to collect and track primary data on environmental impact (including GHG emissions) to deliver reliable, transparent traceability.

The new platform will promote the use of recycled materials and environmentally friendly designs by providing manufacturers who design products from recycled materials with accurate information about their environmental footprint, including proof of origin of recycled materials and data on GHG emissions. Ocean-Plastic-Recycling – Bioplastics

This joint effort demonstrates the two companies’ commitment to contributing to the realization of the common global goal of a carbon-neutral future for humanity.

As per MRC, Teijin says that its subsidiary Teijin Carbon Europe (Heinsberg, Germany) has increased the production capacity of chopped carbon fiber by 40%. The company says that it is responding to the growing demand from European electronics manufacturers in recent years, as well as the current increase in demand for compounds for medical devices.

-Eileen Fisher Foundation launches educational textile waste platform to promote circular economy

The Eileen Fisher Foundation (EFF) has launched HEY FASHION!, a digital platform curated by Pentatonic that refines the complex topic of textile waste into tangible actions to initiate change. The platform contains comprehensive content backed by key industry insights and research.

HEY FASHION! exposes textile waste issues while conveying the financial, environmental and social opportunities that textile circularity can offer. EFF’s larger mission is to prove to the fashion industry the benefits of confronting the climate crisis, urging other brands, foundations, innovators, waste collectors, and consumers to get involved in moving circularity forward. Ocean-Plastic-Recycling – Bioplastics

The platform provides key tools, advice, and information to assist the transition to circularity. Key takeaways educate industry entities on how to drive tangible action, avoid greenwashing, and mitigate risk; influencing improved decisions toward net-zero ambitions. Such content prepares companies to be successful leaders in sustainable fashion during a time of new legislation and rising consumer pressure.

HEY FASHION! aims to kick start a global conversation on how to contribute to a carbon-neutral future by scaling textile recycling infrastructure, promoting underutilized technologies to prevent textiles from going to landfills, and making changes regarding clothing consumption.

“As the leader of an apparel company, I feel an urgency to address the challenges the industry faces regarding textile waste, overconsumption and circular design,” states Eileen Fisher, Founder of EFF. “By inviting Pentatonic to research the current state of circularity, my intention is to facilitate meaningful collective action that moves the industry forward.”

A large barrier to the fashion industry engaging in a circular system is translating the overwhelming amount of research into feasible actions. Pentatonic’s circular consulting team and textile experts provide a clear 8-step action plan:

- Scale sorting

- Invest in recycling

- Make less, buy less

- Work together

- Design to last, design to recycle

- Define and standardize

- Leave fossils in the ground

- People, planet, profit Ocean-Plastic-Recycling – Bioplastics

-Ocean Plastic Recycling Advances Near US

Ocean Recovery Group (ORG), a Deerfield Park, FL-based social-business enterprise, is taking action to combat ocean-bound plastic waste in the Caribbean. Aided by recycling and packaging experts, the group is bringing recycling infrastructure for these plastics to the Dominican Republic.

ORG’s facility in La Vega, Dominican Republic, began processing in February 2022 with the goal of collecting, recycling, and neutralizing 12,000 tons of ocean-bound plastics by year-end. Ocean-Plastic-Recycling – Bioplastics

A lack of recycling infrastructure, inefficient waste-management systems, and the Dominican Republic’s location have made it a significant contributor to ocean-bound plastic. According to ORG, the country currently recycles less than 8% of total plastic.

ORG’s La Vega facility is equipped with a variety of plastic-waste processing equipment, including a MAX-PAK two-ram baler, seven vertical balers, and two plastics lines for washing, shredding, and pelletizing.

The facility, which is an integrated-recycling operation, separates and bales polyethylene terephthalate (PET), natural and colored high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP), as well as cardboard and other paper-grade recyclables.

ORG recently became the first US company to receive three Ocean Bound Plastic Certifications from Zero Plastic Oceans (ZPO), a nongovernmental organization. The certifications pertain to plastic collection, recycling, and neutrality.

A joint venture of international recycling company 4G Recycling, based in Deerfield Beach, FL, and Miami-based packaging supplier AE Global, ORG is certified to sell 100% post-consumer recycled PET, HDPE, LDPE, and PP in the form of bales, pellets, and regrind.

In this exclusive Q&A, Zachary Kirstein, president of ORG, tells us more about his group’s Dominican Republic operation and what lies ahead. Ocean-Plastic-Recycling – Bioplastics

-Performance Polyamide Enables Primerless Painting

Optimized grade of BASF’s Ultramid polyamide enables more sustainable painting of automotive parts.

BASF has launched Ultramid A3EM8 OP, a polyamide grade optimized for painting as it provides a Class A surface finish and high bonding strength. With the new Ultramid grade, a primer is also not required to enhance bonding with paint, thereby reducing VOC emissions. Ocean-Plastic-Recycling – Bioplastics

“As the painting process is simplified with our new Ultramid A3EM8 OP grade, production costs are reduced. The process also reduces the emission of VOCs from the primer,” said Desmond Long, Vice President, Business Management Transportation, Performance Materials Asia Pacific.

As Ultramid A3EM8 OP is resistant to high heat up to 180°C, it maintains dimensional stability during the painting process and under various driving conditions. In addition, the polyamide provides good chemical resistance required for automotive exterior parts. Thanks to these properties, it is now applied to the charging port flap of electric vehicles. The new grade’s toughness and stiffness make it highly durable to broad environmental conditions over its service period. Ocean-Plastic-Recycling – Bioplastics

“We are exploring using this grade on other automotive exterior parts. As plastics offer cost and weight savings compared to metal, our customers want to replace more automotive parts with our high-performance plastics.

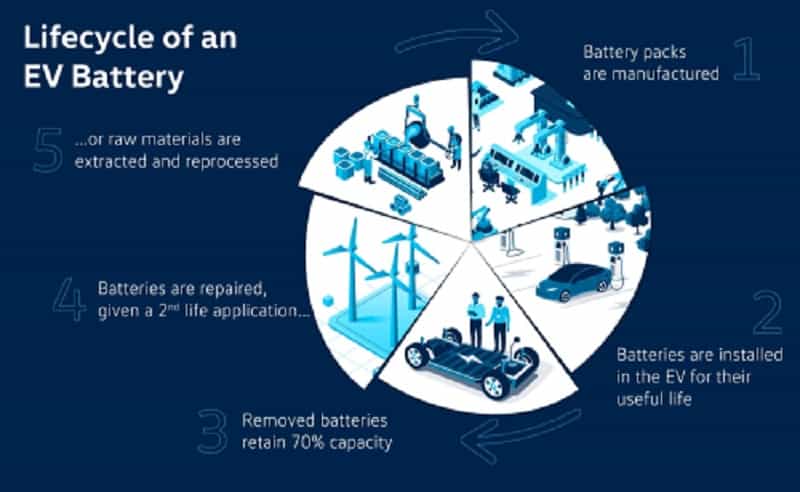

Volkswagen Group of America, Inc. (VWGoA) and Redwood Materials, Inc. (Redwood) will collaborate to create a supply chain to recycle Volkswagen and Audi electric vehicle batteries in the United States, with the goal of providing accessible and more sustainable electric mobility for American drivers. Ocean-Plastic-Recycling – Bioplastics

The collaboration advances Volkswagen Group of America’s strategy to localize all major competencies for its electric transformation, as well as Redwood’s goal of creating the nation’s only closed-loop supply chain for lithium-ion batteries.

The new EV battery recycling collaboration will be facilitated by VWGoA’s nationwide network of approximately 1,000 dealers, starting with the Volkswagen and Audi brands. Key to the collaboration is a holistic approach to the battery lifecycle. By allowing for more sustainable utilization of battery components from the moment vehicles leave the assembly line through the end of their lifecycle, the collaboration can support local battery capacity and expertise as Volkswagen continues its transition to an electrified portfolio.

As Volkswagen Group brands plan to introduce more than 25 new battery electric vehicles to American consumers through 2030, VWGoA aims to begin establishing battery recycling capabilities for current and future vehicles in North America now.

In addition, the new EV battery recycling collaboration will integrate prototype batteries from Volkswagen’s research facilities such as the Battery Engineering Lab (BEL) in Chattanooga. Redwood Materials will work directly with dealers and Volkswagen facilities to identify end-of-life batteries and materials, and then safely package and transport them to their Nevada facilities. Ocean-Plastic-Recycling – Bioplastics

Grupa Azoty introduces on the market the new family of bioplastics based on thermoplastic starch envifill for extrusion and injection molding.

The Polish group Grupa Azoty is introducing on the market under the envifill brand a new family of biobased and compostable thermoplastic starch (TPS) bioplastics according to the EN 13432 standard, with a variable content of renewable raw materials, which can arrive – says the company – even 100%. Ocean-Plastic-Recycling – Bioplastics

They are produced with a proprietary process, without the use of plasticizers, for extrusion processes (envifill F and envifill E), injection molding (envifill M), hot-melt adhesives (envifill G and envifill GP) and 3D printing. Examples of applications are films, rigid containers and packaging for cosmetics, tableware, plant pots, consumables and spare parts for household appliances.

According to the manufacturer, when injection molded, these starchy plastics exhibit good surface aesthetic quality and relatively low shrinkage rates. The granules have a transparent milky color and a pleasant odor.

azoty tps The envifill range includes mass-colored grades, also with natural pigments and special effects.

The biopolymer can also be used as a base or modifier for biodegradable or compostable polymer formulations, such as sustainable hot melt adhesives, which can be used as binders for wood and cellulose-based compounds, a solution already successfully tested in tests with some customers.

In the film extrusion segment, these materials can be used to produce shopping bags, bags for the collection of organic waste, agricultural sheets. They are also suitable – underlines Grupa Azoty – for extruding thin films, with a thickness of less than 15μm, sealed using traditional LDPE welding machines. Ocean-Plastic-Recycling – Bioplastics

The GDP growth in the second quarter extends the revised 4.0% year-on-year expansion in the previous quarter, advance estimates released by the Ministry of Trade and Industry (MTI) showed.

On a quarter-on-quarter seasonally-adjusted basis, Singapore’s GDP was unchanged in the second quarter, after posting an expansion of 0.9% in the first three months of the year.

Singapore’s manufacturing sector expanded by 8.0% year on year in the second quarter, accelerating from the 7.9% growth in the preceding quarter, while construction rose by 3.8%.

Growth during the quarter was supported by output expansions in all clusters, except for the biomedical manufacturing and chemicals clusters.

“The electronics and precision engineering clusters continued to record strong output growth, driven by sustained global demand for semiconductors and semiconductor equipment respectively,” MTI said.

Ocean-Plastic-Recycling – Bioplastics