PET Bottle PLA Textiles 08-11-2021 - Arhive

PET Bottle PLA Textiles

-Bottle PET Polyethylene Paraxylene

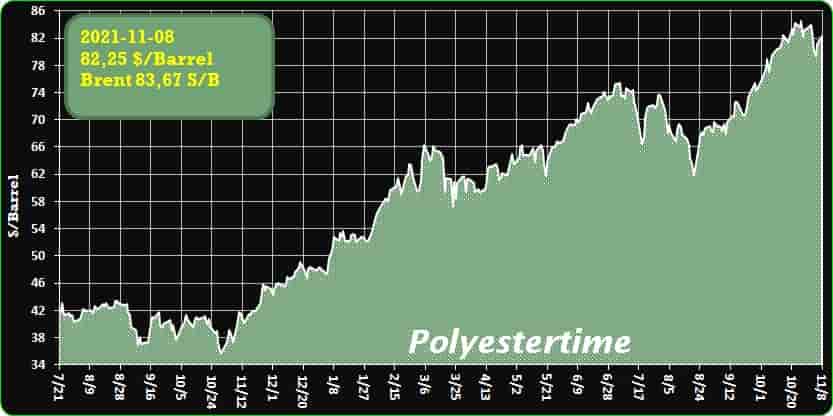

Crude Oil Prices Trend

-Indorama Ventures Hygiene Division Announces Price Increases

Price increases on all polypropylene, polyester, recycled polyester, polylactic acid and bicomponent fibers will be effective December 1

The Hygiene division of Indorama Ventures Public Company Limited (IVL), a global sustainable chemical company, announced price increases on all polypropylene, polyester, recycled polyester, polylactic acid (PLA) and bicomponent fibers effective December 1, 2021, or as contracts allow. These fibers are used in a variety of different hygiene and technical applications, worldwide. Prices will increase up to 15%, depending upon the specific fiber grade.

Shachar Rachim, CEO of the Hygiene Division states, “Due to unprecedented increases in energy, wages, domestic and international freight costs, as well as finishes, additives and all packaging materials, we find it necessary to take this pricing action. These price increases will take place independent of any resin cost changes.”

-Are clothes made from recycled materials really more sustainable?

A growing number of brands are switching to recycled fibers but experts worry people may believe their purchases are impact-free – when that’s far from true

Woven into your clothes is a material that takes on many disguises. It may have the texture of wool, the lightness of linen or the sleekness of silk. It’s in two-thirds of our clothing – and yet most of us don’t even know that it’s there. It’s plastic, and it’s a big problem. PET Bottle PLA Textiles

Today, about 69% of clothes are made up of synthetic fibres, including elastane, nylon and acrylic. Polyester is the most common, making up 52% of all fiber production. Plastic’s unique durability and versatility have made it indispensable to the fashion industry.

“It’s in the waistband of your jeans, your shoes, in practically everything you wear, because plastic is this miracle material,” said George Harding-Rolls, campaigns adviser at the Changing Markets Foundation, an organization that investigates corporate practices.

But there’s a climate cost: the raw material for these fibers is fossil fuels. Textile production consumes 1.35% of global oil production, more oil than Spain uses in a year, and significantly contributes to the fashion industry’s huge climate footprint. Synthetics also continue to have an impact long after production, plastic microfibers into the environment when clothes are washed.

In response, a growing number of brands are switching to recycled versions of synthetic fibers like polyester, often advertising these clothes as the more sustainable” or “conscious”choice.

-Toray to Increase Prices of Automotive Airbag Yarn and Fabrics

Toray Industries, Inc., is announcing the price increase of nylon 66 yarns and derivative fabrics, for automotive airbag application, by around 20% effectively starting from 1st December shipments. PET Bottle PLA Textiles

Significant Shortages of nylon 66 precursor adiponitrile, since 2018, caused price escalation for nylon66 polymer, a principal material in automotive airbag yarns and fabrics. Although the situation thereafter improved somewhat, winter storm Uri, which hit North America in February 2021, caused significant global shortages again and hampered economic activity, leading raw material prices soaring. Such situation caused dramatic rises in nylon 66 prices. On top of that, prices of such secondary raw materials as silicone for coating airbag fabrics have rocketed amid supply shortages. Rising fuel, electricity, and logistics costs are compounding challenges in the airbag business.

Toray accordingly embarked on a project to bolster its total cost competitiveness by slashing expenses and streamlining fixed and variable spending.

-The road towards fully circular polyolefins

Elisabeth Skoda speaks to Trevor Davis, Head of Marketing Consumer Products at Borealis, to discuss strategies and ways forward to address the most pressing sustainability issues of today.

Polyolefin provider Borealis set itself the ambitious goal to achieve a truly circular economy by combining different technologies in a complementary and cascading way through R&D and collaborations across the value chain. As a recent example, the company announced a partnership with Renasci N.V., a provider recycling solutions who created the novel Smart Chain Processing (SCP) concept. This concept is a proprietary method of maximizing material recovery in order to achieve zero waste and enables the processing of multiple waste streams using different recycling technologies under one roof. Mixed waste – plastics, metals, and biomass – is automatically selected and sorted multiple times. After sorting, plastic waste is first mechanically recycled, and then in a second step any remaining material is chemically recycled into circular pyrolysis oil and lighter product fractions, which are used to fuel the process.

He identifies the core challenge around sustainability as finding solutions that address all aspects of the problem, not just a part of it, but is confident that Borealis is on the right track to helping with finding these solutions. PET Bottle PLA Textiles

“I speak daily with brand owners and converters who are passionately working on sustainability. The value chain faces a difficult task to find solutions that tackle both the waste and CO2 challenges at speed and scale. PET Bottle PLA Textiles

-Changing the path forward for plastic

Just like the shift in mindset about global warming, people around the world are waking up to the urgency of the plastics problem. Every year, 8 million tons of plastic waste — most not biodegradable — finds its way into the ocean. And only 9 percent of all plastic waste ever produced has been recycled. The world’s oceans will have more plastic than fish by 2050 unless people stop using single-use plastic items such as plastic bags and plastic bottles, according to figures cited by the United Nations. Over decades, these plastics fragment into microplastics that harm wildlife and seep into the food chain, contributing to a cascade of environmental, financial and health problems.

In response to the crisis, consumers and government regulators are putting pressure on companies to change the way they do business. Consumers want brands to use sustainable materials and some are willing to pay a premium for them. Governments are penalizing companies with fines or taxes if they don’t meet minimum sustainability targets.

This change in attitudes and policy is transforming the way companies think about and treat plastic products and packaging. Consumer products giants such as Coca-Cola, Nestle and Colgate-Palmolive are exerting pressure on recyclers to up their game. Those three have been joined by hundreds of other multinationals, including the Gap, Walmart and IKEA, which have committed to manufacturing products and packaging to enable a plastics circular economy. Adidas, for example, has pledged to shift to use 100-percent recycled polyester in all its products by 2024.

Consumer products giants such as Coca-Cola, Nestle and Colgate-Palmolive are exerting pressure on recyclers to up their game.

With many other companies also setting sustainability goals, the world needs a lot more post-consumer plastic than is available. It is difficult to project future growth of the global recycled plastics market, especially given that compared to megaprojects in virgin plastics, the relatively smaller investments in recycled plastics capacity are faster to implement and may also fly under the radar.

What is clear is that demand far exceeds the estimated supply based on compound annual growth rate (CAGR) projections for the next five years. For instance, the global CAGR of the recycled polyethylene terephthalate (rPET) market is expected to range from 6 percent to 8 percent, meaning that the market would increase from the current $9 billion to a $12 billion-to-$14 billion market in 2026.

A report this spring from the Recycling Partnership, a National nonprofit group, calls for a $17 billion investment over five years in the U.S. residential recycling system to increase the recycling rate to nearly 70 percent. The current rate is about 32 percent. The group says collaborative government and corporate investment could generate more than $30 billion in economic benefits and nearly 200,000 new jobs within 10 years.

-‘UK first’ antibacterial, recycled and recyclable refuse sack launched by Cedo

Cedo’s Good Karma refuse sacks are reportedly made from 100% recycled plastic with incorporated antimicrobial technology. The sacks are intended for household use and can also be recycled, according to the company. PET Bottle PLA Textiles

Martin Burdekin, UK commercial director at Cedo, explains: “We’ve created our very own Good Karma brand made with 100% recycled plastic, including post-consumer flexible plastic film collected and sorted from households.”

The refuse sacks use Bactiglas Antimicrobial technology developed by specialist additive masterbatch manufacturer Wells Plastics, which the company claims killed more than 99% of bacteria – including E. coli and S. aureus – in controlled testing. This contributes to the safe handling of household waste.

According to Carl Birch, sales and marketing director at Wells Plastics: “The Bactiglas active ingredient is a compound that is natural to our environment and toxic to bacteria, whilst being safe for humans.

“Bactiglas is already used in consumer products, medical devices, waste bags and aprons used in hospitals and healthcare settings.

“Bactiglas will provide each bag protection against bacteria which will last throughout its shelf-life.”

In 2014, Cedo began manufacturing bin bags using post-consumer flexible plastic film, such as used sandwich wrappers and other soft plastic packaging, collected from households. PET Bottle PLA Textiles

The company claims that it currently recycles more than 80,000 tonnes of plastic waste every year via its recycling centre in Holland, allegedly one of the largest flexible film recycling centres in Europe. The Holland site supplies manufacturers in Poland and the UK, where production of refuse sacks and bin liners takes place.

-Brazil cuts down import tariffs to fight growing inflation

In a move aimed at curbing inflation, Brazil Friday announced a 10% reduction of import tariffs on 87% of goods and services until December 31, 2022. Economy Minister Paulo Guedes now expects the other Mercosur countries to do the same.

In a joint note from the Ministries of Economy and Foreign Affairs, the Government explained that “rates will be reduced temporarily and exceptionally until December 31, 2022”, under the Montevideo Treaty, which allows countries to take measures aimed at “protecting the life and health of their people.”

The measure will work for Brazil and will not have an impact on items such as automobiles, auto parts, dairy products, textiles, and toys. Products that are in Mercosur exception regimes, such as capital goods, were also left out. “Brazil continues to participate fully in the ongoing negotiations in Mercosur. The Ministries of Economy and Foreign Relations reiterate the exceptional and temporary nature of this Resolution while reaffirming their commitment to Mercosur.”

Argentine Foreign Ministry sources admitted Brasilia had previously informed Buenos Aires it was going to take this decision temporarily. Argentine sources said the measure was suggested by the Government of President Alberto Fernández to appease both Brazil and Uruguay, who had asked for greater reductions.

The revision of Mercosur’s Common External Tariff (CET) is an ongoing negotiation which began two years ago and was resumed in the Oct. 8 meeting between Argentina’s Foreign Minister Santiago Cafiero and his Brazilian counterpart Carlos França, during which a consensus was reached to reduce the CET by 10%.

The definition adopted by the Ministry of Economy of Brazil (Resolution 269/2021 of the Executive Committee of CAMEX Management – Foreign Chamber of Commerce) is of a transitory and exceptional nature and respects the parameters agreed between both countries and on which work continues within Mercosur. “There is a consensus between both countries regarding maintaining the unity of the bloc and negotiating jointly with third countries, in the sense of what was expressed in the Joint Communiqué of 8 October last.”

Following Brazil’s decision Friday, Economy Minister Paulo Guedes said he expected the other three members of Mercosur would follow suit shortly.

According to reports from Buenos Aires, there will soon be a meeting of coordinators of the Common Market Group to update Mercosur’s tariff structure in accordance with the current conditions of regional and world trade.

Minister Guedes explained that “at this moment there is a strong inflationary pressure and facilitating the entry of imports will allow prices to adjust.”

Meanwhile, Montevideo insisted on the “need to modernize” Mercosur. The Foreign Ministry and the Ministry of Economy and Finance of Uruguay issued a joint statement describing “Brazil’s decision is understood within the current framework of Mercosur as an imperfect Free Trade Zone.”

PET Bottle PLA Textiles