Petrochemical PET Resin Smart News 25-11-2019 - Arhive

Petrochemical PET Resin Smart

Petrochemical Polymers Ethylene Plastic Prices

Crude Oil Prices Trend

-US PE offers not tempting all European buyers in spite of knockdown prices

Polyethylene (PE) imports into Europe from the US are not always tempting buyers in spite of the very low prices.

– US HDPE at knockdown prices

– Buyers target end-year discounts

– Global GDP forecasts down

The grades most affected by US imports are high density polyethylene (HDPE) and linear low density polyethylene (LLDPE), with levels well below €900/tonne FD (free delivered) NWE (northwest Europe) for some HDPE grades in particular.

-Europe, Asia tackle PET supply length, US to remain short

Feedstock capacity additions affect PET sentiment

US to remain net short amid delayed mega-plant

The European and Asian polyethylene terephthalate and polyester markets will present a bearish outlook in 2020, led by capacity additions in Asia, slowing global economies and trade tensions. The US, on the other hand, looks set to remain a net importer of PET due to the delayed start-up of a mega-plant.Petrochemical PET Resin Smart

-INEOS OPENS ADVANCED POLYMERS PILOT PLANT IN ITALY

INEOS has opened its new advanced polymer pilot plant in Rosignano, Italy. This plant will help to develop and produce advanced products which will incorporate plastic waste diverted away from landfill or incineration. One example of the many products it will develop will include light weight car parts.Petrochemical PET Resin Smart

The plant supports a more sustainable and circular approach to polymer production, saving CO2 as well as directing plastic waste from landfill back into valuable polymer products. The new plant is part of INEOS’s global 100 million research and development program, which supports INEOS customers globally.Petrochemical PET Resin Smart

-Trevira wins Brandenburg Innovation Award

Trevira has been named winner of the “Brandenburg Innovation Award for Plastics and Chemistry 2019” by the Brandenburg Ministry of Economic Affairs for its new flame retardant, UV-resistant polyester yarn.

The yarn,https://www.tevonews.com/fibres-yarns-news/2226-trevira-wins-award-for-flame-retardant-fibre which is available in a variety of colours, is specially designed for outdoor applications.

It was selected for the award by a jury of five, with the prize-giving ceremony taking place at the Cluster Conference Plastics and Chemistry on 21 November.

Trevira GmbH’s innovative new yarn combines multiple qualities in a way never before achieved for a polyester textile. Petrochemical PET Resin Smart

-Toxic fumes from car exhausts are being converted into fertiliser

Toxic fumes from the exhaust of a diesel or biofuel engine could be worth a fortune as scientists discover a way to trap and convert them into nitric acid.

The resulting chemical is used in a range of industries from the production of nylon fabrics and fertiliser to rocket fuel and explosives.

University of Manchester scientists developed a ‘metal-organic-framework’ (MOF) system that uses water and air to capture and convert the pollutant.

‘The global market for nitric acid in 2016 was $2.5billion’, said Martin Schröder from Manchester University.

-SIGMA teaches injection moulding know-how for process optimisation

SIGMA is to hold a seminar series to help consumers deal with potential unforeseen circumstances within the injection moulding process.

The series, ‘Optimisation strategies in the injection moulding process’, developed in cooperation with the VDI, aims to jointly develop recommendations for action in order to optimise the part, mould, and process. Petrochemical PET Resin Smart

-Simulating deformation of inserts or core pins

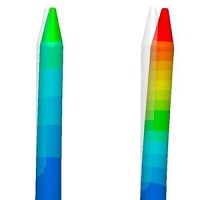

Simulative comparison of the deformation of core pins made of tungsten carbide (left) and 420 stainless steel (right) at the end of the filling of the cavity — the material with the lower modulus of elasticity deforms three times more under constant process conditions.

Virtual moulding can help make decisions in mould design. Comparing different mould materials in the simulation can help prevent deformation during the filling.

There are many questions that injection mould manufacturers confront daily regarding the variety of mould materials which are available in the market.

What type of steel should be used for which part of the mould? Whether it is the thermal conductivity of the steel used for the cavity insert, the diameter of a suitable ejector pin or even the mechanical stability of the core pins.Petrochemical PET Resin Smart

-TOMRA: Making the future of food sustainable

Nicolai Prytz, sustainability and strategy director at TOMRA, has looked at how businesses, consumers and policymakers can help make the future of food sustainable.

With a rapidly growing population, adopting sustainable production practices on a global scale is an imperative to safeguard the future of our planet. Petrochemical PET Resin Smart

The food supply chain is certainly one area where there is urgent need for improved sustainability. Without food – this precious resource currently being wasted across the supply chain – society as a whole becomes unable to function.

-Brugnoli presents new capsule collection with Lycra

From underwear to beachwear, urban wear to athleisure – the fabrics made using Explosive Technology by Brugnoli, enhanced by Lycra fibre specialties, are the perfect resource for style and performance, the company reports.Petrochemical PET Resin Smart

Brugnoli, an Italian company specialised in high-end circular knit fabrics for sports, swimwear, lingerie, ready to wear, has presented a special collection of outfits made using fabrics based on Explosive Technology at this month’s MarediModa show in Cannes.

-Seventh Starlinger recycling line

In July 2019, the recycling company Calex S.R.L. installed a Starlinger recycling line for post-consumer film in Satu Nou de Jos in the Romanian municipality Groși – already the seventh line supplied by Starlinger recycling technology.

At Calex, a family-run company in the Romanian municipality Groși, approx. 600-700 tons of plastic waste are recycled each month.

In July, the company installed a plastics recycling line type Recostar dynamic 105 C-VAC supplied by Starlinger recycling technology.Petrochemical PET Resin Smart

With four Starlinger lines running in Romania and three more at the company headquarters Candi Plastic Recycling in Sollenau/Austria, the owners already operate a total of seven lines supplied by the Austrian machinery manufacturer.

-From plastic bottle to … plastic bottle: how Cape Town recycles

About 90% of South Africa’s waste is not recycled – but tracking the ‘virtuous’10% is an interesting journey.

Each year, South Africans produce about 40 million tonnes of general waste, only 10% of which is recycled, according to the State of Waste Report published by the Department of Environmental Affairs in 2018. The other 90% ends up in landfills or waste storage facilities around the country. But what happens to the 10% of materials that have a second, third, or even a fourth, chance at life? Petrochemical PET Resin Smart

The South African government lagged behind many countries in implementing public recycling programmes, with its pilot project in 2004 in Cape Town. Only in 2006 did public recycling come to Gauteng and KwaZulu-Natal, and then slowly spread to the rest of the country

-Study forecasts more increases in US oil production

Even though there appears to be signs of weakening in the crude oil and natural gas production boom in the U.S., a new report from the Energy Information Administration (EIA) predicts continued production increases through 2020.

EIA revised its Short-Term Energy Outlook this week forecasting a 119,000 barrels per day (b/d) increase in oil production in 2020 over 2019.

EIA says oil production will increase to 12.3 million b/d this year, which is up from 11 million b/d in 2018. Petrochemical PET Resin Smart

-The Most Advanced Lignin Valorization Process Will Create a Wave of New Bio-Materials

METNIN™ Technology combines high solubility of lignin and enzymatic treatment, designed to specifically modify and activate any lignin. Discover the potential mid-range applications (e.g. polyurethane foams, sizing and coating) of this revolutionary lignin valorization technology.Petrochemical PET Resin Smart

Currently, only about 2% of the lignin available from the pulp industry is commercialized, mainly from the sulfite process.

-Groupe Renault designs textile from recycled materials

Groupe Renault along with Filatures du Parc, a spinning mill in the Tarn region of France, and Adient Fabrics, an automotive seat supplier in Ariège, France, has designed a textile product made exclusively from recycled materials such as safety belts, textile scrap from the automotive industry and polyester fibres from the recycling of plastic bottles (PET).

The material has been used in the interior of the New Renault Zoe, in Zen and Intens finishes. The material was designed under a project – “àfiler” (“to thread”) – initiated by Groupe Renault in 2015. Petrochemical PET Resin Smart

Petrochemical PET Resin Smart