Petrochemicals CarbonFiber Sustainability 02-10-2020 - Arhive

Petrochemicals CarbonFiber Sustainability

Crude Oil Prices Trend

-Covestro to acquire DSM resins, functional materials businesses for USD1.9 billion

DSM says it has reached an agreement to sell its resins and functional materials, and associated businesses, including DSM Niaga, DSM additive manufacturing, and the coatings activities of the DSM advanced solar business, to Covestro for an equity value of EUR1.6 billion (USD1.9 billion), said Chemweek.

Completion of the transaction is expected in first half 2021, subject to customary conditions and approvals. The businesses included in the transaction represented EUR1.01 billion of DSM’s 2019 total annual net sales and EUR133 million of DSM’s 2019 total EBITDA, the company says. DSM will provide re-stated figures for its materials cluster ahead of its third-quarter results, it says.

Meanwhile, DSM anticipates a book profit on the transaction to be recognized on closing. It expects to receive approximately €1.4 billion net in cash following closing, including repayment of the net debt of the businesses being sold to Covestro, and after transaction costs and capital gains tax.

-EcoGraf Presents at Benchmark’s Battery Day, Emphasises on Closing the Carbon Loop

Summary

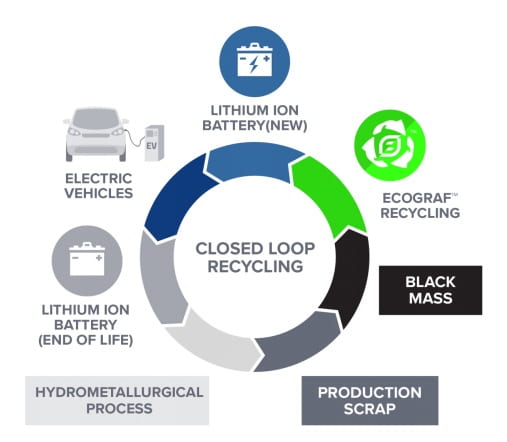

At Benchmark’s Battery Day event, EcoGraf discussed on the positioning in the Anode market expanding across mining, purification and processing and recycling from production scrap and Black mass.

Vertical Integration of the Graphite business to ensure high quality anode components and superior battery performance. Petrochemicals CarbonFiber Sustainability

EcoGraf seeks to develop Kwinana processing facility and the Epanko processing plant.

EcoGrafTM purification process reports production recovery of 98.6-100% from scrap and 98-99.6% recovery from black mass.

An innovative Battery Anode producer, EcoGraf Limited (ASX:EGR) presented its Lithium-ion battery recycling results at the Benchmark Mineral Intelligence’s Battery Day on 23 September 2020. This presentation was on the back of Tesla’s Battery Day event.

-Nordmann extends its additives portfolio to include antioxidants and UV stabilizers

Under the brand name NORANTOX, Nordmann now offers its own product range of antioxidants and UV stabilisers for applications in plastics, coatings, construction and elastomers.

The products are available for purchase throughout Europe.

Antioxidants and photoprotective agents are among the most frequently used additives in the plastics industry. Petrochemicals CarbonFiber Sustainability

Nordmann says without these additives, advanced applications would be unable to perform under harsh environmental conditions.

Both during processing and across the lifetime of finished products, they are used to prevent molecular degradation and to inhibit or slow the rate of oxidation in plastics.

Nordmann already offers its customers an extensive product portfolio of plastic additives (including flame retardants such as the NORD-MIN range, rheology modifiers, impact modifiers and pigments) and intends to further develop its portfolio for this important and growing market.

-JLR to Use ECONYL Nylon Made from Ocean & Landfil Waster for Luxury Interiors

Jaguar Land Rover is working with ECONYL nylon to develop high-quality interiors made from ocean and landfill waste.

Next-generation Jaguar and Land Rover models will feature floor mats and trims made with ECONYL® fibre from recycled industrial plastic, fabric offcuts from clothing manufacturers, fishing nets from the farming industry, and those abandoned in the ocean– known as ‘ghost nets’. Petrochemicals CarbonFiber Sustainability

This commitment to designing sustainable luxury interiors using responsibly sourced and recycled materials is part of Jaguar Land Rover’s Destination Zero emission, with innovation helping to make environments safer and cleaner while offering customers a premium, sustainable option.

-Toxins in plastic blamed for health, environment hazards

Report warns exposure to toxic chemicals in everyday consumer goods could result in cancers, damage to immune system. Petrochemicals CarbonFiber Sustainability

Evidence suggests several chemical additives in plastic products and packaging are poisoning consumers, harming the environment and undermining recycling initiatives, according to a new study, which calls for the development of safer alternatives.

In a report published on Wednesday, the Regional Activity Centre for Sustainable Consumption and Production (SCP/RAC), warned that exposure to even small amounts of harmful plastic chemical additives could result in cancers, damage to immune and reproductive systems, impaired intellectual functions, and developmental delays.

-TOMRA makes beverage container recycling work in any conditions

Global reverse vending leader TOMRA has unveiled its robust solution for big-city recycling, the TOMRA S1 Rugged.

Designed to withstand challenging weather conditions, this innovative reverse vending machine (RVM) has been designed for returning drink containers for recycling in semi-outdoor, metropolitan locations. TOMRA S1 Rugged hits the US market today and will roll out to other markets in the future. Petrochemicals CarbonFiber Sustainability

TOMRA S1 Rugged can withstand demanding use as well as increased exposure to the elements in metropolitan areas. It has been tested to comply with product standards for water resistance, making it ideal for semi-outdoor locations. The reverse vending machine’s touchscreen display is easy to read, even in bright sunlight. With TOMRA Flow Technology, the TOMRA S1 Rugged accepts containers in a smooth, fast flow, with top-of-the line system integrity.

-Graham Recycling Company celebrates 30 years

Graham Packaging, an industry leader in the design and manufacturing of innovative and sustainable packaging solutions, is celebrating the 30th anniversary of the Graham Recycling Company (GRC).

The facility opened on 26 September 26, running only one line and one shift. It now operates three lines with three round-the-clock shifts.

CEO Mike King said: “When the GRC began operations 30 years ago, Graham Packaging was well ahead of the industry regarding recycling best practices. Today, the company continues its innovative trajectory with investments that will further support and expand the capabilities of our recycling company.” Petrochemicals CarbonFiber Sustainability

The benefits of having an in-house recycling plant are twofold. Not only has it helped Graham become one of the largest suppliers of bottle-grade recycled plastic containers in North America, but it’s also enabled the company to become more sustainable. By diverting plastic from landfills, the recycling facility helps save energy and natural resources, as well as substantially reduce greenhouse gas emissions.

-Kuhne Anlagenbau presents proven Triple Bubble technology for recyclable barrier films

Mono material film structures is the name of the modern solution for all packaging applications that require both high performance and environmental friendliness. However, the production of full PO films poses challenges for plastics processors: they have to adapt and expand their manufacturing equipment and meet all the requirements of the food industry. With its Triple Bubble technology, Kuhne Anlagenbau GmbH offers a solution to all film manufacturers for the economical production of uniformly oriented mono-material films that are both high quality and directly sealable.

MD Jürgen Schiffmann said: “We have been building Triple Bubble blown film lines for over 20 years and thus have an enormous wealth of experience both in terms of machine technology and formulation development. Petrochemicals CarbonFiber Sustainability

-Asia petrochemicals drift in quiet trade as NE region goes on holiday

Spot petrochemical trades in Asia were largely muted at the start of October as most of the northeast region was on holiday.

Before going on a long holiday, China delivered upbeat September manufacturing data, which could buoy up overall sentiment upon players’ return a week later.

Economic data from other countries in Asia, however, calls for a more cautious market outlook. Petrochemicals CarbonFiber Sustainability

The slowdown in market activity for some petrochemicals started in the weeks leading to the holiday in China, limiting price movements.

-Will better PFY and downstream market continue in Oct?

Polyester and downstream markets showed signals to improve recently. Firstly, fabric market kept turning better since Aug, with rising orders, profit and run rate. Stocks of grey fabric and feedstock inventory of grey fabric plants gradually declined. Overall downstream market witnesses apparently eased pressure compared with the first half of year, especially in knitting and home textile sectors. Petrochemicals CarbonFiber Sustainability

Secondly, price of PFY moved up in end-Sep despite of falling feedstock price, and sales improved, resulting into decreasing stocks and recovering profit. Cash flow of PET fiber chip has turned to positive territory. Better PFY market was mainly stimulated by improving downstream fabric market and falling feedstock price.

Petrochemicals CarbonFiber Sustainability