Petrochemicals CrudeOil AdipicAcid PHA 11-07-2020 - Arhive

Petrochemicals CrudeOil AdipicAcid PHA

-Pandemic encourages Europe chems ‘never-ending’ move to specialties – bank

European chemicals “never-ending move” away from commoditised chemicals towards specialties remains the primary driver for the industry, with the coronavirus pandemic increasing the focus on the resilience of business models, analysts at Credit Suisse said on Thursday.

The majority of European chemicals firms have pushed further downstream to defend against large-scale basic chemicals capacities coming onstream in lower-priced feedstock regions.

At the same time, the weak demand brought on by the economic collapse this year has increased focus on defensive stocks.

Investors have also moved to focus on safe havens during the unrest of 2020 so far, as evidenced by the rock-bottom of even negative interest rates seen for debt issued by some mature economies, and this has continued to drive up the pricing of specialised chemicals stocks against cyclical peers.

-Carbonlite expands capacity at Dallas Plant

CarbonLITE, the world’s largest recycler of plastic beverage bottles, has expanded capacity at its Dallas plant in order to provide more recycled PET to its customers.

The company, with additional facilities in Riverside, CA and Reading, PA, collectively processes a total of over 7 billion bottles annually, producing recycled PET that is made into new bottles in a closed-loop, bottle-to-bottle system.

New equipment in the 220,000 square-foot, $62 million Dallas plant, opened in 2017, includes an additional extrusion line, a critical step in the recycling process, that has enabled CarbonLITE to increase the plant’s capacity by 20 percent.

The company’s customers include Coca-Cola, Nestle Waters North America and PepsiCo.

Petrochemicals CrudeOil AdipicAcid PHA

-Polypropylene Recycling Coalition aims to enhance circularity in US

National non-profit organisation The Recycling Partnership has launched a new industry collaboration to enhance circularity in the US.

The initiative, Polypropylene Recycling Coalition, has an initial funding target of $35m over five years. Petrochemicals CrudeOil AdipicAcid PHA

It is part of The Recycling Partnership’s Pathway to Circularity Initiative.

The industry collaboration was created to improve polypropylene recovery and recycling in the country. It is expected to support the development of the end-market of high-quality recycled polypropylene.

Keurig Dr Pepper, Braskem, and the Walmart Foundation are the founding members of the coalition.

-Reprocessors demand overhaul of ‘outdated’ PRN system

Plastics reprocessing firms across the UK have joined forces to call on the government to overhaul the “outdated” packaging recovery note (PRN) compliance system as a matter of urgency.

Firms including Bright Green Plastics, which recycles more than 40,000 tonnes of plastics waste a year, believe that the current PRN and packaging export recovery note (PERN) system will, if left unchecked, jeopardise the future of the recycling industry, make a mockery of the upcoming plastics tax, and potentially have a lasting impact on both the environment and jobs. Petrochemicals CrudeOil AdipicAcid PHA

In another body blow to the plastics reprocessing industry, due to lockdown, the price of crude oil has dropped in recent months, drastically bringing down the price of virgin plastics.

-Effort seeks to examine PET thermoform recycling

A group organized by the Foodservice Packaging Institute seeks to define the most cost-effective and practical ways to recover this material.

The Foodservice Packaging Institute (FPI) Falls Church, Virginia, has organized a group that will examine polyethylene terephthalate (PET) thermoform packaging recycling, noting that it is conducting a study on the PET thermoform packaging stream and defining the most cost-effective and practical pathways for recovery. Through the study, the group says it hopes to establish a common understanding of the most significant opportunities to increase PET thermoform recycling.

According to a report from Grand View Research, the global thermoform packaging market was estimated at $39.86 billion in 2018, growing at a compound annual growth rate of 4.7 percent from 2019 through 2025. PET accounted for the largest share in the material segment of the global thermoform packaging market in 2018. The plastic is used in cups, lids, clamshells, bowls, produce, deli, bakery and take-out containers, as well as other types of consumer packaging. Petrochemicals CrudeOil AdipicAcid PHA

-Questions & Answers: A European strategy for plastics

Why do we need a European strategy for plastics?

Plastics are everywhere but too much of it is used only once before thrown away. It ends up polluting the environment, depriving the economy of a valuable resource.

According to estimates, only 5% of the value of plastic packaging material retains in the economy, the rest is lost after a very short first-use. The annual bill accounts for between €70 and €105 billion. Europe cannot afford this.

Furthermore, unrecycled plastic takes hundreds of years to break down. The million tonnes of plastic litter that end up in the oceans every year are one of their most visible and alarming signs of the plastics problem, causing growing public concern. And with a single market for goods, this is a problem that necessarily requires a joint European response. Petrochemicals CrudeOil AdipicAcid PHA

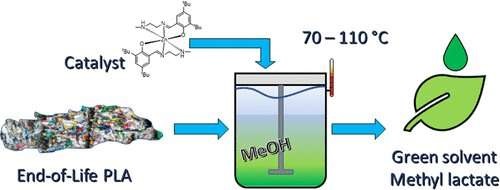

-Chemical recycling makes useful product from waste bioplastic

A faster, more efficient way of recycling plant-based “bioplastics” has been developed by a team of scientists at the Universities of Birmingham and Bath.

The team has shown how their chemical recycling method not only speeds up the process, it can also be converted into a new product — a biodegradable solvent — which can be sold for use in a wide variety of industries including cosmetics and pharmaceuticals. Petrochemicals CrudeOil AdipicAcid PHA

Bioplastics, made from polylactic acid (PLA), are becoming increasingly common in products such as disposable cups, packaging materials and even children’s toys. Typically, once they reach the end of their useful life, they are disposed of in landfill or composted, biodegrading over periods of up to several months.

-European project to reduce marine plastic litter

A European project to develop biodegradable and biorecyclable textile fibres and coatings to be used in fishing gear and clothing has been initiated by 14 partners from nine European countries. The four-year project, Glaukos, financed with over € 4.1 million from the Bio-based Industries Joint Undertaking (BBI JU), aims to reduce marine plastic pollution. Petrochemicals CrudeOil AdipicAcid PHA

BBI JU is a public-private partnership between the European Commission (Horizon 2020 programme) and the Bio-based Industries Consortium (BIC).

Abandoned, lost or discarded fishing gear (ALDFG) accounts for about 27 per cent of all marine litter found in European oceans, the equivalent of 11.000 tons ALDFG entering the marine environment each year. Evidence has been mounting that the synthetic fibres which make up much of the clothing and fishing gear, are also a major source of textile-related microplastic pollution in marine environments. Clothes simply wear off during use and in particular during washing. It was found that in a typical wash, up to 700.000 microparticles can be released.

-Rialti patents compounding process

Petrochemicals CrudeOil AdipicAcid PHA

-Plastics as a materials system in a circular economy

Plastics have transformed our modern world. With a range of outstanding properties, they are used in an ever-widening range of applications. However, the linear economy of their use means that a large volume of plastics is discarded after use.

It is believed that approximately 80% of the estimated total 6.3 Bt of plastics ever produced have been discarded, representing not only a huge loss of valuable resources, but mismanaged waste is also the origin of an ever-increasing environmental disaster.

Strategies to prevent loss of materials resources and damage to the environment are elements of a circular plastics economy that aims to maintain plastics at their highest value for the longest time possible and at the same time improve the economy and prevent detrimental environmental impact.Petrochemicals CrudeOil AdipicAcid PHA

The latter in particular is driving recent changes in policies and legislation across the world that are rapidly being introduced in order to solve these environmental issues.

The achievement of a circular economy will require not only innovative technical developments, but also major economic investment and changes to business practice coupled with significant changes in social behaviour.

This paper summarizes the complex and highly interrelated technical issues and provides an overview of the major challenges, potential solutions and opportunities required to achieve and operate a circular plastics economy.

Petrochemicals CrudeOil AdipicAcid PHA