Petrochemicals CrudeOil Bioplastics 14-10-2020 - Arhive

Petrochemicals CrudeOil Bioplastics

Crude Oil Prices Trend

-Textile lighting systems demonstrated

The incorporation of lighting into vehicle interior textiles is growing in popularity with manufacturers, and in this video, lighting specialist Munda and textile developer Aunde demonstrate some of the effects that can be achieved.

According to Munda, the basic components of textile lighting systems are at least one LED light source and a textile material – a fabric that acts as a light guide. The light is fed into the fabric’s fiber ends and can be emitted from its side (lateral emission). The fabric is provided with suitable light-scattering surface structures at the desired light output points for this purpose. However, the light can be emitted – additionally or exclusively – at the end of the fibers too (axial emission).

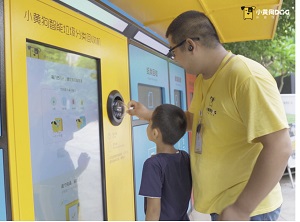

-Innovative Smart Recycling Machines in China

China, the world’s largest nation, holds a population of approximately 1.393 billion people. China’s rapid population growth contributes to a significant increase in solid waste production and mismanagement. In 2018 alone, China produced nearly 228 million tons of solid waste. Currently, one company is creating smart recycling machines that will hopefully address this issue. Petrochemicals CrudeOil Bioplastics

The Xiao Huang Gou Environmental Technology Company (XHG) installed smart recycling machines in 39 Chinese cities to manage waste production. This resulted in successfully integrating a “complete waste recycling ecological chain.” XHG smart recycling machines cover three of the most densely populated cities in China: Beijing, Shanghai and Tianjin. XHG increases access to recycling systems and educates the general public on the classification and delivery of recyclable materials. This helps reduce the threat of waste mismanagement in China.

-Yanfeng Automotive Interiors And KOSTAL Cooperate On Innovative Smart Interior Surfaces

With the new strategic partnership, both companies are drawing on the market trend toward the integration of HMI operating controls into high-quality surfaces in vehicle interiors.Petrochemicals CrudeOil Bioplastics

Yanfeng Automotive Interiors (YFAI), one of the world’s leading suppliers of instrument panels, cockpit systems, door panels and floor consoles, and KOSTAL, a global leading automotive supplier of mechatronic HMI-components, announced the formation of a new strategic partnership. The CEOs of both companies signed a Memorandum of Understanding with the intent of cooperating in the field of smart interior surfaces.

With the new strategic partnership, both companies are drawing on the market trend toward the integration of HMI operating controls into high-quality surfaces in vehicle interiors.

-Indorama Ventures Joins the World Economic Forum’s Global Plastic Action Partnership

Indorama Ventures Public Company Limited (IVL) today announced that it has joined the World Economic Forum’s Global Plastic Action Partnership (GPAP). The global multi-stakeholder partnership aims to reduce plastic leakage into the environment and is driving the transition to a circular economy for plastics.

This partnership is aligned with Indorama Ventures 2019 commitment to increase recycled content volumes of PET by at least 750,000 tonnes, pledging US$ 1.5 billion towards achieving this target by 2025.Petrochemicals CrudeOil Bioplastics

Mr. Yashovardhan LOHIA, Chief Sustainability Officer, Indorama Ventures said, “We are proud to join the World Economic Forum’s Global Plastic Action Partnership. By joining GPAP we will advance our shared goal of ending PET plastic waste. Harnessing the convening power of the World Economic Forum, GPAP is bringing together governments, businesses, and civil society to forge circular solutions – at both the global and national levels. Our recycling facilities across the world can close the loop and deliver a circular economy for PET plastic.”

-Britain Introduces Standard for Biodegradable Plastic

Companies will need to prove their products break down into harmless wax containing no microplastics or nanoplastics.Petrochemicals CrudeOil Bioplastics

Currently, most plastic products in litter persist in the environment for hundreds of years, but a recently developed biodegradable plastic may change that.

A new British standard for biodegradable plastic is being introduced which aims to standardize confusing legislation and classifications for consumers, reports The Guardian.

According to the new standard, plastic that claims to be biodegradable will have to pass a test to prove that it breaks down into a harmless wax which contains no microplastics or nanoplastics.

Polymateria, a British company, made the benchmark for the new standard by creating a formula that transforms plastic items such as bottles, cups and film into a sludge at a specific moment in the product’s life.

-Impact of the upcoming polyester staple fiber futures

The trading of polyester staple fiber futures will be launched on Zhengzhou Commodity Exchange on Oct 12.

Lots of attention has been drawn to the upcoming PSF futures and its impact on the market.Petrochemicals CrudeOil Bioplastics

In China’s PSF market, the trading is conducted between PSF producers and downstream spinners and some traders also participate.

However, due to the preparation of PSF futures since last year, several PTA and MEG traders and investors have taken part in PSF market, who usually use commodity futures to hedge. Since trading of PSF futures is approved to start from Oct 12, those traders are expected to participate.

-SE Asia PP hits eight-month high, supply tightness to continue

Southeast Asian polypropylene (PP) spot prices have risen to an eight month high, with the market likely to remain supported by regional supply tightness in the near term.

Average all-origins PP flat yarn prices were pegged at $1,000/tonne CFR (cost and freight) southeast (SE) Asia on the week ended 9 October, up $15/tonne from the week before.

All-origins spot prices last touched the $1,000/tonne back in February 2020, and have since seen sweeping peaks and troughs amid volatile market dynamics.

Petrochemicals CrudeOil Bioplastics

-Sinopec starts ethylene production at new Zhanjiang refinery

China’s Sinopec has started operation of a 800,000 tons-per-year ethylene facility at its Zhanjiang refinery, reported Reuters with reference to the company’s statement.

The refinery, located in the southern Chinese coastal city of Zhanjiang, commenced operation of its 200,000 barrel per day crude oil refining units in June.

As MRC informed before, Sinopec SABIC Tianjin Petrochemical Co. (SSTPC), a 50-50 joint venture of Sinopec and SABIC, completed the debottlenecking of its ethylene cracker on 11 July 2020, adding another 30,000 tons/year output to its current capacity. Followed the expansion, the Tianjin based plant become the country’s largest compressor unit, producing 1.3 million tons of ethylene annually.Petrochemicals CrudeOil Bioplastics

Ethylene and propylene are feedstocks for producing polyethylene (PE) and polypropylene (PP).

According to MRC’s ScanPlast report, Russia’s estimated PE consumption totalled 1,496,500 tonnes in the first eight months of 2020, up by 5% year on year. Shipments of all ethylene polymers increased, except for linear low desnity polyethylene (LLDPE). At the same time, PP shipments to the Russian market reached 767,2900 tonnes in the eight months of 2020 (calculated using the formula – production minus exports plus imports – and not counting producers’ inventories as of 1 January, 2020). Supply increased exclusively of PP random copolymer.

-Siemens to build large CO2-free hydrogen production plant in southern Germany

Siemens Smart Infrastructure and WUN H2 GmbH signed a contract to build one of the largest hydrogen production plants in Germany, said Hydrocarbonprocessing.

It will be built in Wunsiedel in the north of Bavaria. With a power intake of six megawatts in the initial development phase, the plant will run solely on renewable energy and will be CO2-free. The electrolysis plant from Siemens Energy will have the capacity to produce over 900 tons of hydrogen per year in this first phase. When fully expanded, it will be able to supply up to 2,000 tons. Groundbreaking is scheduled for the end of this year and commissioning at the end of 2021.Petrochemicals CrudeOil Bioplastics

Germany has pledged to be greenhouse gas-neutral by 2050. To this end, all sectors that use energy, such as transportation and industry, must press ahead with decarbonization. The plant in Wunsiedel will serve as a model for all of Germany. It will convert the renewable energy available in this region, e.g., from photovoltaics and wind power, into storable hydrogen (H2), making it available for applications in mobility and industry. This is especially useful when, on sunny and windy days, more energy from renewable sources is produced than needed.

-INEOS Styrolution presents StyLight at ITHEC 2020

INEOS Styrolution, the global leader in styrenics, will showcase advancements of the composite StyLight at this year’s virtual edition of the ITHEC conference and exhibition.

The brand StyLight comprises a portfolio of materials offering unique combinations of surface aesthetics, structural stiffness and easy processability. StyLight offers a solution for a range of demanding automotive interior and exterior applications as well as for applications in other industries such as electronics or toys/ sports/ leisure. The most recent developments presented at ITHEC 2020 make the spectrum of applications suitable for the StyLight composite even broader.Petrochemicals CrudeOil Bioplastics

At its virtual booth, INEOS Styrolution will demonstrate three advancements of the StyLight material: a combination of SAN-based StyLight and EPS foam resulting in intrinsic good adhesion between both styrenics based materials and an increased mechanical/ impact performance; aesthetic natural fibre-based StyLight composite offering new bio-based solutions; and advancements related to new aesthetic PP-based StyLight introduced in 2019.

Petrochemicals CrudeOil Bioplastics