Petrochemicals Nonwovens PET Automotive 30-08-2021 - Arhive

Petrochemicals Nonwovens PET Automotive

Petrochemicals Nylon6 Polyethyleneterephthalate Trend

Crude Oil Prices Trend

Nonwovens technology supplier Dilo Group will demonstrate a range of its latest, tailor-made machinery solutions at October’s INDEX exhibition.

Located at booth No. 2010, Dilo’s portfolio will include the latest equipment developments from fibre opening to the finished felt.

With its Hyperpunch technology the company has developed a simplified, elliptical needle beam drive which allows a more uniform stitch distribution in the pre-needling process, particularly when used in combination with the new needle pattern 6000X.

In a complete needling line, this felt homogenization process can be improved further by using the new needle pattern 8000X which is a milestone in the needle pattern development process and results in end-product surfaces with low markings over a wide range of advances/stroke. Petrochemicals Nonwovens PET Automotive

-Covestro and partners develop cost-effective smart surface production process

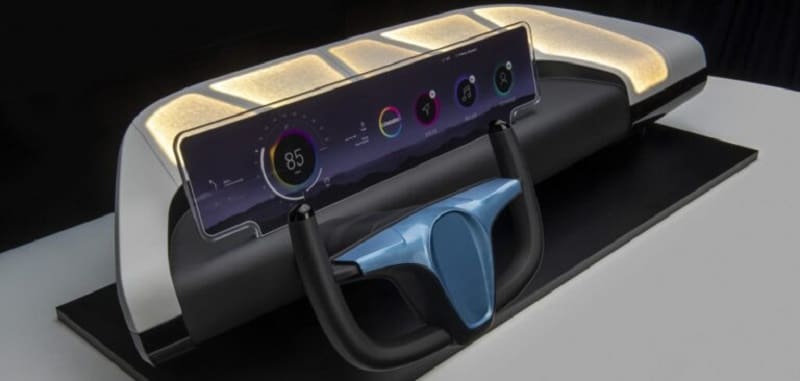

Automotive interior technology developer Covestro says it has been investigating the development of seamless surfaces suitable for the integration of intelligent cockpit features, to create greater design freedom for engineers while still allowing cost-effective production. Petrochemicals Nonwovens PET Automotive

Together with materials developer Votteler Lackfabrik, laser texture specialist Reichle, and Merck, a manufacturer of pearl-effect pigments, Covestro says it has developed a concept for the manufacture of interior components that can incorporate smart functionality yet have a seamless surface.

The company notes that car manufacturers and their suppliers face the challenge of integrating smart functions such as display and ambient lighting and touch control, in addition to a wide range of visual and haptic surface properties. The resulting parts must be durable and able to be manufactured as cost-effectively as possible to achieve broad acceptance in the industry.

-Indonesia faces new delay in plans to raise the mandatory bio-content

Indonesia’s plans to raise the mandatory bio-content in its palm oil-based biodiesel to 40% may face further delays, after the high price of the vegetable oil has made the programme too costly, a senior government official told Reuters.

Indonesia, the world’s largest palm oil producer and exporter, has a mandatory biodiesel programme with 30% palm oil content, known as B30, but intends to expand the use of the oil for energy to save on fuel imports. Authorities had planned to increase the mix to 40% in July this year, but the timetable for the B40 programme is now unclear. Petrochemicals Nonwovens PET Automotive

“We don’t have a timeline yet for B40, although from the technical side, we’re ready,” Dadan Kusdiana, a director general at the energy ministry, said in an interview. He said implementing B40 in 2022 will be “challenging”. Indonesia funds its biodiesel programme with proceeds from palm export levies.

However, authorities have revised levy rules three times since last year as they sought to support the biodiesel programme after prices soared, but without hurting exports. Malaysian palm oil futures hit a record of 4,560 ringgit (USD1,089.35) a tonne on Aug. 12 and have been trading around 4,300 ringgit recently, about 60% higher than a year earlier.

Shell Catalysts & Technologies (SC&T) has successfully commercialized OparisNext, their latest generation catalyst, at Ningbo Zhongjin PetroChemical Co, Ltd. Ningbo Zhongjin is one of the leading paraxylene (PX) producers in China, said Hydrocarbonprocessing. Petrochemicals Nonwovens PET Automotive

Over the past decades, the Oparis series has offered proven catalytic benefits for key PX producers, resulting in more efficient operations and significant financial benefits. With the latest patented zeolite innovation in the OparisNext catalyst, it serves as the bedrock of attaining high ethylbenzene conversion while achieving excellent PX-ate at high space velocity (refer to charts shown below). These performance indicators are crucial in maximizing margins and strengthening the competitive position of Ningbo Zhongjin PetroChemical in the PX industry.

“We are very glad to be the first user of OparisNext, very happy to see that all the performance data can meet the guarantees. The excellent EthyleneBenzene (EB) conversion, low C8 ring loss are helping Ningbo Zhongjin to maximize operating margin. We believe the new catalyst will help us be more competitive in the PX market in China,” said Mr Li Libo, Operating Vice-President of Ningbo Zhongjin. Having total PX capacity of 1600 KTA, the EthyleneBenzene Reformer (EBR) unit has undergone a catalyst changeout to OparisNext and successfully commissioned in 2021 with stellar performance results exceeding guarantee requirements.

-Robinsons ready-to-drink Lipton ice tea and drench move to 100 percent recycled plastic bottles

This summer, Robinsons, Lipton Ice Tea and drench 500ml bottles are moving to 100% recycled plastic (rPET). Petrochemicals Nonwovens PET Automotive

The 500ml on-the-go bottles are the first to use recycled plastic from a new rPET manufacturing facility in North Yorkshire.

The facility, built by Esterform Packaging Limited following Britvic’s £5m investment support in 2019, is powered by 100% renewable energy and provides Britvic with a secure supply of quality food-grade rPET in the UK.

Mark Tyne, Esterform’s Managing Director, said: “Our £20 million project to produce 42,000 tonnes of recycled food grade PET could not have got off the ground without Britvic’s support and we look forward to working together to rollout recycled PET usage across Britvic’s portfolio.”

By switching Robinsons, Lipton Ice Tea and drench 500ml bottles to rPET, Britvic will save 1,354 tonnes of virgin plastic every year. This is in addition to the 1,900 tonnes already saved by Ballygowan Mineral Water and Fruit Shoot Hydro switching to rPET bottles.

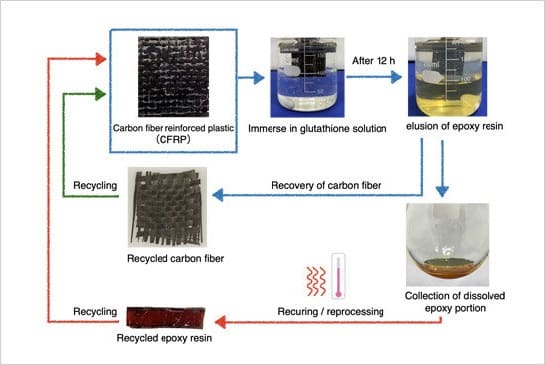

-New strategy for promoting the reuse of carbon fiber reinforced plastics

Epoxy resin is a type of thermoset resin commonly used in glue, paint and composite materials. NIMS and ISMA have developed a new thermoset plastic recycling system capable of easily decomposing epoxy resins in an aqueous solution of a naturally derived peptide. The use of this system may promote the reuse and recycling of plastics, including carbon fiber reinforced plastics (CFRP)—carbon fibers combined with an epoxy resin matrix—by a wide range of industries.

Environmental pollution caused by plastics—particularly in the marine environment—has raised global concern about urgent need to promote plastic waste recycling. Some recycling methods have already been developed to decompose thermoplastic resins used in containers and packaging through thermal and chemical processes, and efforts are underway to put recycling plants into practical use. On the other hand, a method for recycling thermoset resins, including epoxy resins, has yet to be developed due to their poor thermal degradability and low solubility in available solvents. Petrochemicals Nonwovens PET Automotive

-Indian petchem demand to rise tenfold by 2050: CPMA

The Indian petrochemical industry would have to increase its production capacity tenfold in order to meet higher demand by 2050, according to Kamal Nanavaty, president of India’s Chemicals and Petrochemicals Manufacturers’ Association (CPMA). Petrochemicals Nonwovens PET Automotive

Nanavaty spoke at the CPMA – Argus Petrochemical Online Forum on 25 August.

It is estimated that India’s consumption will double every nine years, at the current 8 pc/yr growth rate. Nanavaty highlighted that Indian polymer demand growth has historically been higher than India’s GDP growth and the trend is expected to hold this year.

To meet this demand the industry would have to be more forward looking and decide if it should continue expanding its capacities in the current scattered manner or take on a clustered approach, which is something that the Indian government has been pushing for.

-Kumho Petrochemical seeking recycled SBR source material

Synthetic rubber supplier Kumho Petrochemical Co. Ltd. is joining forces with a U.S. company to explore the use of post-consumer plastics waste in the production of synthetic rubber. Petrochemicals Nonwovens PET Automotive

The project, with chemical recycling specialist Agilyx Corp. of Tigard, will focus particularly on producing styrene — a fundamental building-block for synthetic rubber — from post-use polystyrene, Jong-Hoon Baek, CEO of Kumho Petrochemical, said.

A key component of the agreement calls for the companies to study the development and construction of a chemical recycling project in South Korea, using Agilyx’s chemical depolymerization technology to produce styrene monomers from post-use polystyrene.

The styrene monomers would then be used as a virgin equivalent raw material to produce solution styrene-butadiene rubber (SSBR), a key component for the manufacture of tires.

“The collaboration with Agilyx will give Kumho Petrochemical an opportunity to propose a new line of eco-SSBR products to most of our customers who prefer sustainable products,” Mr. Baek added.

The project will expand the market for post-use recycled polystyrene into “new, high growth and technically demanding applications,” Agilyx CEO Tim Stedman said.

“The potential to use waste plastic to create high performance SSBR for the manufacture of tires is a very exciting example of our technology’s ability to create a new life for plastic.”

-India to shortly call green hydrogen bids for 4 GW electrolyser capacity

Premium Green hydrogen is produced by splitting water into hydrogen and oxygen using an electrolyzer powered by electricity from renewable energy sources such as wind and solar New Delhi: As a part of its energy security strategy, India plans to shortly kick-start its green hydrogen pathway by calling bids for 4 gigawatt (GW) electrolyser capacity. Petrochemicals Nonwovens PET Automotive

According to a statement from the union power ministry on Friday, this was conveyed by union power and new and renewable energy minister Raj Kumar Singh to US special presidential envoy for climate John Kerry via a telephone call on Thursday.

This comes in the backdrop of Prime Minister Narendra Modi in his Independence Day speech announcing a National Hydrogen Mission.

“He (Singh) added that India would be conducting competitive bids for green hydrogen in next 3-4 months to pave the road for viable usage of hydrogen as a fuel. India is looking at bids for 4000 MW of electrolysers capacity,” according to the statement.

With the current cost of green hydrogen produced by electrolysis estimated at around ₹350 per kg, the plan is to more than halve it to ₹160 per kg by 2029-30

New Delhi: As a part of its energy security strategy, India plans to shortly kick-start its green hydrogen pathway by calling bids for 4 gigawatt (GW) electrolyser capacity.

Petrochemicals Nonwovens PET Automotive