Petrochemicals Plant Bottles 11-08-2021 - Arhive

Petrochemicals Plant Bottles

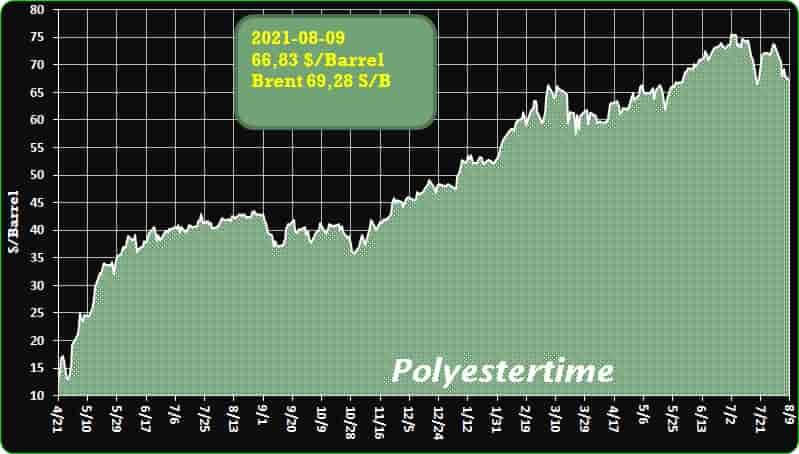

Crude Oil Prices Trend

-Teijin Aramid, OMP Racing composite Formula E racing suit raises the bar for protective performance

Ultra-light meta-aramid fiber garment maximizes both the safety and comfort of the Envision Virgin Racing Formula E team, harnessing flameproof, flexible and high-performance qualities.

Aramid fiber producer Teijin Aramid BV (Arnhem, Netherlands) has helped engineer a new protective motor racing suit that will be worn for the first time at the Berlin Formula E ‘E-Prix’ on Aug. 14, an annual race of the single-seater, electrically powered Formula E championship.

According to the company, the ultra-light suit harnesses the protective qualities of Teijinconex neo, a high heat-resistant and dyeable meta-aramid fiber, to provide professional racing drivers with outstanding levels of comfort, protection and safety.

Teijin Aramid claims that this is the world’s first use of Teijinconex neo for professional motor racing.

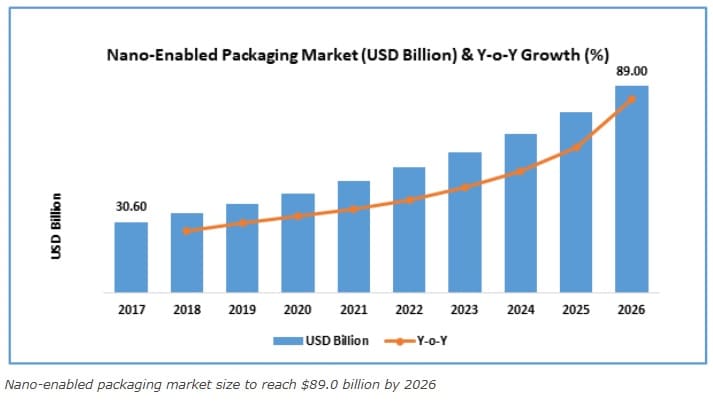

-Nano-enabled packaging market size to reach $89.0 billion by 2026

Nano-enabled packaging market to grow at a CAGR of 12.7% during forecast period

The global nano-enabled packaging market is estimated to reach US $ 89.0 billion by 2026 growing at a CAGR of 12.7% during the forecast period, according to a new study published by Polaris Market Research. The report ‘Nano-Enabled Packaging Market Share, Size, Trends, & Industry Analysis Report, By Type (active, intelligent, others); By End-User (food and beverages, pharmaceutical, personal care, others); By Regions: Segment Forecast, 2018 – 2026’ provides an extensive analysis of present market dynamics and predicted future trends. In 2017, the food and beverage segment accounted for the highest market share. Asia-Pacific is expected to be the leading contributor to the global market revenue in 2017.

Nano-enabled packaging in food & beverage segment

The increasing demand for packaged food products, growth in eCommerce, and an increasing proportion of technologically inclined consumers support the market growth. Increasing demand for fresh fruit and vegetables and stringent government regulation to promote the use of nano-enabled packaging for improved food safety boosts the market growth. Petrochemicals Plant Bottles

Nano-enabled packaging in pharmaceutical industry

The growing use in the pharmaceutical industry, development of intelligent packaging, and rise in food-led export activities would accelerate the adoption of nano-enabled packaging solutions during the forecast period. Various brands operating in the packaging market are adopting nano-enabled and smart packaging to enhance shelf appeal and brand exposure. New marketing techniques incorporating smartphone apps and codes are being used to attract consumers, thereby increasing the industry size.

Use of nano-enabled packaging is expected to increase significantly during the forecast period. Use of nanotechnology in food packaging increases the shelf life of food products, minimizes spoilage, ensures food safety, and repairs the tears in packaging. Nano-enabled packaging solutions are also capable of alerting consumers about the safety of the product, and sometimes release preservatives to extend shelf life of food in package.

-Will we shift from fossil-based to biobased plastic packaging?

Biobased plastic packaging is capturing market share from traditional petroleum-based plastic packaging. With a number of technologies available or under development, biobased plastic packaging could eventually dominate.

There’s no doubt bioplastics is a growth area. “For example, the biobased polyethylene terephthalate (PET) market is predicted to grow at a compound annual growth rate of 68.25% until 2019, per…[Technavio’s] report, Global Biobased Polyethylene Terephthalate (PET) Market 2015-2019,” says Patrick Krieger, assistant director of regulatory and technical affairs at SPI: The Plastics Industry Trade Association, Washington, DC. Petrochemicals Plant Bottles

Some biobased plastics such as polylactic acid and polyhydroxyalkanoate are biodegradable; others such as biobased polyethylene terephthalate (PET) and biobased, high-density polyethylene (HDPE) are not. However, these biobased versions of traditional petroleum-based resins result in containers and packaging components that are identical in appearance, function and recyclability. As a result, biobased PET, HDPE and PP packaging resins can serve as drop-in replacements for conventional resins.

-Revolutionary, sustainable technology

Loop’s depolymerization technology breaks down previously unrecyclable PET (polyethylene terephthalate) plastic and polyester fiber waste into their base building blocks, dimethyl terephthalate (DMT) and monoethylene glycol (MEG), using low heat and no added pressure. Petrochemicals Plant Bottles

DMT and MEG Monomers

These DMT and MEG monomers are then purified and polymerized (or re-combined) into Loop™ branded PET plastic and polyester fiber. The end product is made from 100% recycled content.

Loop™ branded PET is high purity, virgin-quality plastic which is suitable for use in food-grade packaging — like the kind used to make water bottles.

Parent companies, Cargill and GC, have authorized NatureWorks to invest in excess of $600 million in the new fully integrated 75,000 ton per year facility, which includes lactic acid, lactide, and polymer manufacturing sites planned for construction beginning in the second quarter of 2022.

Continuing its global manufacturing expansion plan, NatureWorks, the world’s leading manufacturer of low-carbon polylactic acid (PLA) biopolymers made from renewable resources, has obtained final authorization from parent companies, GC International Corporation Company Limited, a subsidiary of PTT Global Chemical Public Company Limited (GC) and Cargill Incorporated (Cargill), to build a new Ingeo™ PLA manufacturing complex in Thailand. NatureWorks plans to invest in excess of $600 million to construct the complex, which will include production sites for lactic acid, lactide, and polymer, making it the world’s first PLA facility designed to be fully integrated. Petrochemicals Plant Bottles

-Alpek newly acquired rPET facility to start up in Q3 2021

Alpek (Monterrey, Mexico) expects to finish commissioning and begin production at a Reading, Pennsylvania, recycled polyethylene therephthalate (PET) facility in the third quarter of 2021, reported S&P Global with reference to CEO Jose de Jesus Valdez’ statement.

DAK Americas, Alpek’s US subsidiary, bought the facility in late-May for USD98.1 million at an auction in the bankruptcy case of California recycled PET producer CarbonLite

Valdez said the recycling and pelletization facility is one of the largest recycled PET units in the Americas, and can produce food-grade pellets. Petrochemicals Plant Bottles

The acquisition brought Alpek’s total recycled PET capacity to 282,000 mt, “reaffirming its position as the largest PET recycler in the Americas and achieving the company’s target of supplying its customers with 25% of rPET content before 2025,” Valdez said.

Thailand-based Indorama Ventures, the world’s largest virgin PET manufacturer, bought CarbonLite’s rPET facility in Dallas, Texas, at the bankruptcy auction for USD63.87 million, and TGS Shelf II Acquisition LLC, an affiliate of Houston private equity firm The Sterling Group, bought a third CarbonLite facility in Riverside, California, at the auction for USD57.5 million, according to bankruptcy records.

-Magna cuts 2021 revenue forecast as chip shortages expected to reduce vehicle output

But sales more than doubled to $9 billion, reflecting a global light vehicle production increase of 58 per cent.

Magna International Inc. has cut its revenue forecast for the year due to an expected reduction in global light vehicle production caused by ongoing semiconductor chip shortages. Petrochemicals Plant Bottles

“As a result of significant production disruptions due to the global semiconductor chip shortage that continues to negatively impact global light vehicle production, our sales, Adjusted EBIT and diluted earnings per share came in well below our expectations for the second quarter of 2021,” Magna officials said in an Aug. 6 news release. “The second quarter of 2020 included unprecedented, industry-wide production suspensions due to the COVID-19 pandemic, while the second quarter of 2021 included the production disruptions due to the ongoing global semiconductor chip shortage, making the quarters difficult to compare.”

-Now there’s recycled swimwear for the eco-conscious

In the first half of the year, before the spectre of the delta variant arose, consumers were in a liberated mood.

Along with airline tickets and high heels, swimsuits became must-haves for shoppers eager to escape quarantine. Petrochemicals Plant Bottles

Globally, consumers spent US$2.7 billion on swimwear in the first half of 2021 — a 19% jump from the same period in 2019, according to industry analysts at NPD Group.

For decades now, most swimsuits have been made with Spandex, which was invented by materials scientists at DuPont in 1959 as a lighter, more breathable alternative to rubber.

The petroleum-based material quickly became standard in the apparel industry, and in 1972, Speedo became the first company to sell Spandex swimwear.

As of 2017, polyester and Spandex make up about 65% of the fabrics used in the swimwear market, according to Allied Market Research.

-ANDRITZ to Exhibit its Nonwovens and Textile Production Technologies At Techtextil Russia 2021

International technology Group ANDRITZ will be presenting its innovative nonwovens production and textile solutions at Techtextil Russia 2021 in Moscow, Russia, from September 14-16 (hall 7.2 at Textima booth 72B10)

The broad ANDRITZ product portfolio covers state-of-the-art nonwovens and textile production technologies such as air-through bonding, needlepunch, spunlace, spunbond, wetlaid/WetlaceTM, converting, textile finishing, airlay, recycling, and natural fiber processing. Petrochemicals Plant Bottles

Recycling technologies by Andritz

Recently, ANDRITZ acquired Laroche SAS, a leading supplier of fiber processing technologies such as opening, blending, and dosing, airlay web forming, textile waste recycling, and decortication of bast fibers. The product portfolio further complements and enlarges the ANDRITZ Nonwoven product range. One focus of this product range lies on complete recycling lines for post-consumer and industrial textile waste to produce fibers for re-spinning and/or nonwoven end uses. Customer awareness and regulations are pushing apparel brands to recycle their waste in their own products. Recycled fibers can also be used in the nonwovens industry for various applications such as automotive, insulation, mattresses, and furniture felts. To support ANDRITZ customers, a process know-how team is at customers’ disposal to conduct customized trials in our advanced technical center located at the ANDRITZ Laroche facilities.

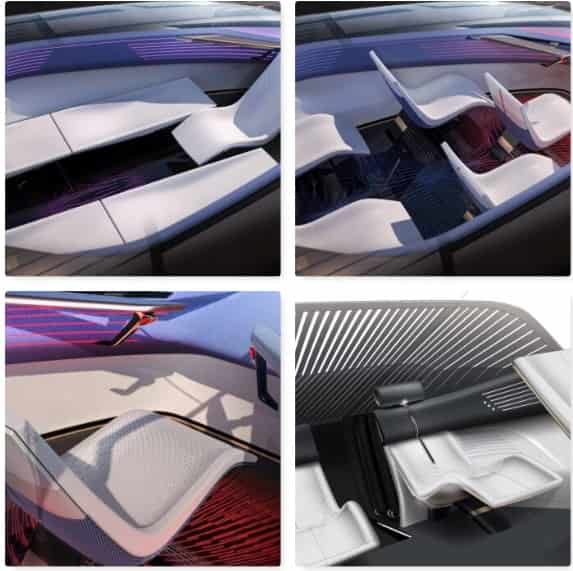

-Teorema concept car from Pininfarina with different interior modes

Pininfarina has released renderings of its latest concept, the Teorema, an EV that the auto maker envisions as an autonomous vehicle that creates interactions between passengers and the environment. Petrochemicals Plant Bottles

“Pininfarina has always looked to the future using concept cars as an innovation tool to chart the direction and introduce new visions in terms of usability and technology in the automotive industry,” commented Kevin Rice, chief creative officer, Pininfarina.

“Teorema, in particular, wants to give people back the pleasure of living the car, driving and traveling, without the frustrations of increased congestion and other compromises, all while integrating AI, 5G and the latest technology to drive passengers towards new incredible experiences along the journey.”

As passengers enter, the rear of the Teorema opens, while the roof extends upward and forward, and the floor then lights up to guide occupants to their seats. Within the Teorema, passengers can then decide on whether they want to interact, sleep or rest depending on the situation.

Petrochemicals Plant Bottles