Recycled Packaging Polymer Stabilizers 06-10-2021 - Arhive

Recycled Packaging Polymer Stabilizers

Crude Oil Prices Trend

-Researchers Infuse Bacteria with Silver to Improve Power Efficiency in Fuel Cells

Living energy-recovery systems utilizing bacteria found in wastewater offer a one-two punch for environmental sustainability efforts

A UCLA-led team of engineers and chemists has taken a major step forward in the development of microbial fuel cells — a technology that utilizes natural bacteria to extract electrons from organic matter in wastewater to generate electrical currents. A study detailing the breakthrough was recently published in Science.

“Living energy-recovery systems utilizing bacteria found in wastewater offer a one-two punch for environmental sustainability efforts,” said co-corresponding author Yu Huang, a professor and chair of the Materials Science and Engineering Department at the UCLA Samueli School of Engineering. “The natural populations of bacteria can help decontaminate groundwater by breaking down harmful chemical compounds. Now, our research also shows a practical way to harness renewable energy from this process.”

The team focused on the bacteria genus Shewanella, which have been widely studied for their energy-generation capabilities. They can grow and thrive in all types of environments — including soil, wastewater and seawater — regardless of oxygen levels.

Shewanella species naturally break down organic waste matter into smaller molecules, with electrons being a byproduct of the metabolic process. When the bacteria grow as films on electrodes, some of the electrons can be captured, forming a microbial fuel cell that produces electricity.

-Micrillon bicomponents for infection prevention

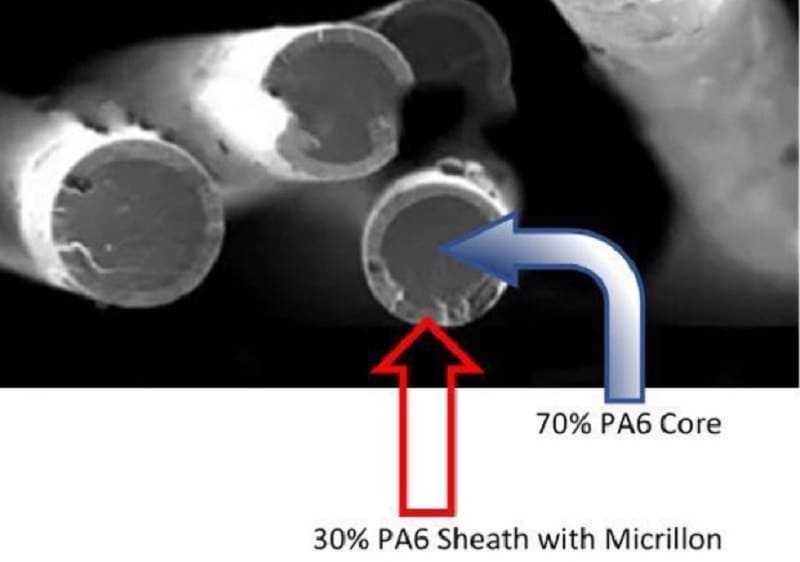

Micrillon is a new additive made by Illinois-headquartered UMF Corporation in bicomponent microfibres that can be converted into a wide range of long-lasting, reusable products, including towels, cubicle curtains, socks, gloves, walk-off mats, reusable N95 rated face masks and colour-coded microfibre cleaning products.

Leading manufacturers are using these high performance microfibres in materials targeting infection prevention in hospitals, hotels, cruise lines, long term care, and many other industries. Recycled Packaging Polymer Stabilizers

“The introduction of Micrillon microfibre puts an end, once and for all, to any question about recontamination related to reusable products,” said UMF Corporation CEO George Clarke. “Some manufacturers and distributors of disposable products – including cubicle curtains, microfibre mops, and wipers – have generated controversy around the risk of reusable products, such as microfibre wipers recontaminating a patient room, even after being laundered. This ignores the fact that after laundering, wipers used in hospitals are immersed in an EPA-registered disinfectant before use – effectively killing bacteria and inactivating viruses.”

-SONGWON announces global price increases for its phosphorous based polymer stabilizers

Songwon Industrial Co., Ltd. today announced global price increases for its phosphorous based polymer stabilizer products to reflect the sudden rise in raw materials costs. The price increases are effective immediately for SONGWON’s phosphites antioxidants: SONGNOX® 1680, SONGNOX® 6260 and SONGNOX® PQ (including subsequent blends) as well as SONGSORB® 7120.

The price adjustments are aimed at offsetting the higher cost of yellow phosphorous raw materials and their limited availability caused by decree 2021-792 made by provincial authorities of Yunnan, China in September, which restricted the high energy consuming production of yellow phosphorous.

Phosphorous trichloride and phosphorus oxychloride (yellow phosphorous derivatives) are key raw materials in SONGWON production and the price for these materials continues to escalate. Recycled Packaging Polymer Stabilizers

SONGWON anticipates the global availability of these raw materials to be substantially reduced and is working with high priority to minimize the effects of these exceptional circumstances. It will also be continually monitoring the cost developments and reviewing its prices accordingly.

Circular Materials collaboration with Canadian Beverage Container Recycling Association to advance Ontario collection program

Circular Materials and the Canadian Beverage Container Recycling Association (CBCRA) are developing a comprehensive recycling program for beverage containers collected in blue bins and public spaces across Ontario.

The Blue Box Regulation requires producers to assume responsibility for the collection and management of blue box materials from municipalities between 2023 and 2025. CMO and CBCRA will support producers by establishing a collection system for beverage containers, carrying out consumer promotion and education, reporting to the regulator and meeting Ontario’s targets to collect and manage 75 percent of beverage containers supplied in the province by 2026, and 80 percent by 2030.

Ontario’s Blue Box Regulation will require producers selling beverage containers in the province to meet management targets based on beverage containers supplied to consumers not only for personal, family and household use, but also for business purposes. Beverage containers include aluminum cans, glass bottles, milk cartons, juice boxes and plastic bottles. Recycled Packaging Polymer Stabilizers

As much as 30 percent of beverage products are consumed away from home. As a result, beverage producers will require a collection system to supplement blue box collection to meet the targets in the Blue Box Regulation.

-Repsol produces renewable hydrogen from biomethane in Spain

Repsol has produced its first renewable hydrogen derived from biomethane at its Cartagena, Spain, refinery complex, said the company.

In a major milestone for the clean fuel economy, Repsol has produced renewable hydrogen using biomethane as a raw material in Cartagena, Spain – and the company says it is a world first.

Announcing its achievement today (Oct 4), Repsol said the produced ten tonnes of hydrogen, made from 500MWh of biomethane, has been used to manufacturer low-carbon fuels. Recycled Packaging Polymer Stabilizers

Part of Repsol’s effort to utilise state-of-the-art technologies to transform waste into products with high value, the effort is believed to have prevented approximately 90 tonnes of CO2 into the atmosphere.

Aside from the above project, Repsol is already deploying a multitude of projects throughout the renewable hydrogen value chain, such as the developments of a 2.5MW and a 10MW electrolyser in Petronor.

Repsol has committed to installing renewable hydrogen production with a capacity of 552 megawatt equivalent by 2025 and 1.9 gigawatt equivalent by 2030 on the Iberian peninsula.

-Seating supplier to harness recycled CO2 technology

Adient, a global supplier of seating systems for the automotive industry, and Covestro, a polymer specialist, have joined forces in an effort to improve the sustainability of the former’s seat products.

From November, Adient will be integrating Cardyon, a polyol made using Covestro’s CO₂ technology, as a sustainable feedstock for the production of hot cure molded polyurethane foam. Adient uses these foams as cushioning in its automotive seating systems. Recycled Packaging Polymer Stabilizers

This supply chain-related sustainability move helps to further reduce Adient’s Scope 3 emissions as calculated by the Greenhouse Gas Protocol. Based on the principle of the circular economy, the Covestro’s CO₂ technology reuses carbon dioxide as a material source by integrating up to 20% of CO₂ into polyol production. The smart contribution helps to preserve fossil resources and close the carbon loop.

David Nash, VP components EMEA at Adient, remarked, “Adient is pursuing multiple ways to reduce its CO₂ footprint, further raising sustainability, and this is especially true for the production of polyurethane foam. By choosing Cardyon by our partner Covestro, we have made another valuable step toward more sustainable production of our high-class seating systems. In addition to the high quality of our products, this means further differentiation and added value for our customers.”

-EU LIFE Project “Absolutely Circular” recognised by the European Commission’s “Innovation Radar”

Market maturity of the innovation is categorised as “Market ready”

Market creation of the innovation is categorised as “The innovation addresses the needs of existing markets/ existing customers”

Frankfurt, October 5, 2021 – The EU LIFE Project “ABSolutely Circular”, addressing ABS production from chemically recycled PS waste, has been featured by the European Commission’s Innovation Radar and will be showcased on the organisation’s website[1] as one of “the great EU-funded innovations”. Project partner INEOS Styrolution has been identified as “Key Innovator” by the organization. Recycled Packaging Polymer Stabilizers

Petra Inghelbrecht, Global Sustainability Manager at INEOS Styrolution and project leader for the ABSolutely Circular research project, comments: “This recognition is a strong motivation for all partners participating in this project. We are privileged to work with strong technology partners like Indaver who share our vision of treating waste as a valuable resource.”

-Influence of “dual control” on CPL and nylon 6 industry

The “Dual Controls” on energy consumption and energy intensity – or the amount of energy consumed per unit of GDP, have exerted impacts on the operating rate of all industries to various degrees. Nylon 6 industrial chain, from caprolactam, to nylon 6 polymer, textile filament and downstream weaving and knitting factories are all affected. By September 29, the operation changes along the industry have been summarized in below figure.

The “Dual-Control” target refers to the energy consumption intensity (“energy consumption per unit of GDP”) and total energy consumption. The energy consumption per unit of GDP of 2021 is aimed at about 3% this year. But more than half of the provinces failed to achieve the goal of controlling energy consumption and intensity in the first half of the year. Recycled Packaging Polymer Stabilizers

CPL: supply tight, still price may fall

To briefly summarize the market operation in September, CPL market has been driven up by still tight supply-demand structure and the quickly rising benzene cost. We had mentioned at the end of August that CPL would be still tight in September. In Sep, downstream nylon 6 HS chip demand was not good due to the weak performance of textile end. But nylon 6 CS chip market trading had several rounds of expansions, especially the high-viscosity CS chip, which was boosted by industrial filament and cord fabric plants.

-Siemens and Technip to make JV to decarbonize olefin production processes

Technip Energies and Siemens Energy announced an exclusive agreement to jointly develop, commercialize, and license the ROC technology to decarbonize olefin production processes, said Hydrocarbonprocessing.

The ROC technology employs a dynamic reactor system that replaces conventional furnaces used for pyrolysis when manufacturing light olefins – the building blocks for chemical products used in everyday materials, from packaging to polymers.

The ROC technology offers driver flexibility, and when driven by electric-powered motors or hydrogen-fired gas turbines, the technology leads the path to decarbonize the process used to produce light olefins. The decarbonization impact is even more significant when the electric power or hydrogen fuel is derived from renewable sources. The ROC process, once fully commercialized, is also expected to have better first pass olefins yields with similar operating costs compared to the currently commercially available technologies. Recycled Packaging Polymer Stabilizers

-ŠKODA AUTO uses eco-materials in its vehicles and is researching biological raw materials

› Innovative eco-material for potential use in the interior, patent pending

› Residual materials and natural products come from local sources wherever possible

› ŠKODA AUTO’s Technical Development is collaborating with the Technical University of Liberec on the research and development of sustainable materials

› ŠKODA AUTO will be making even greater use of natural and recycled materials in the production of future models Recycled Packaging Polymer Stabilizers

Mladá Boleslav, 22 September 2021 – In collaboration with the Technical University of Liberec, ŠKODA AUTO’s Technical Development department has developed a sustainable, ecological material and applied for a patent. The innovative raw material is made from sugar beet pulp. ŠKODA AUTO is also researching another material based on the reed plant miscanthus. Both could be used in the interior of new ŠKODA models in the future, for example for the door trim and decorative inlays in the dashboard. Using a purpose-built OCTAVIA, ŠKODA AUTO demonstrates the wide range of possible applications for the new materials.

Johannes Neft, ŠKODA AUTO Board Member for Technical Development, explains: “We aim to play a pioneering role in the area of sustainability. We are taking a holistic approach to this issue, and we are addressing much more than just the CO2 emissions of our vehicle fleet; we are also focusing on researching and using ecologically sourced materials and investigating, for example, how materials such as coconut fibres or rice husks can be used in the future.”

Recycled Packaging Polymer Stabilizers