Renewable Hydrogen Bottling – Closes Repreve the PET bottles circuit ? 28-07-2023 - Arhive

Renewable Hydrogen Bottling

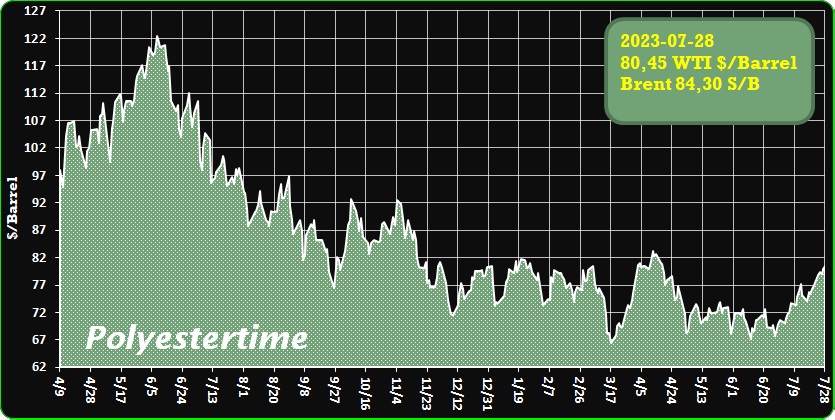

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Niagara Bottling, an American beverage manufacturing company, has recently announced a significant investment of $48 million to expand its bottling facility in Temple, Texas, USA

The expansion project, confirmed by the Temple Economic Development Corporation (EDC), will involve the construction of a new warehouse at the existing plant, generating around 14 new job opportunities in the region.

Brian Hess, the Executive Vice President of Niagara Bottling, expressed the company’s enthusiasm for the expansion, stating that the new facility would enable them to handle the distribution of new beverage products and cater to their valued customers in the area. He also acknowledged the support provided by the city of Temple and the Temple EDC, praising the region’s competitive and attractive advantages, including its strategic location, robust transportation infrastructure, and skilled workforce, which have fostered a strong partnership between Niagara and the local community.

The initial plans for a new bottling plant in Temple were unveiled by Niagara in 2019, with an initial investment of $90 million. The 450,000 square foot facility was subsequently established in the Temple Industrial Park and expanded in 2020. This latest investment showcases Niagara’s continued commitment to the region and the growth of its operations within the city. Renewable Hydrogen Bottling

Temple EDC President and CEO, Adrian Cannady, expressed excitement about the expansion and its positive implications for both the city and Niagara Bottling. He described Niagara as a valuable member of the community’s flourishing food and beverage industry, highlighting the company’s steady growth in recent years. With a reputation for being a prime location for food and beverage companies, Temple attracts both national brands and homegrown businesses seeking to thrive in the region.

Established in 1963, Niagara Bottling is a family-owned and operated company specializing in private-label bottled water distribution across the United States. The company places a strong emphasis on sustainability and actively participates in water conservation efforts. Niagara is also known for manufacturing 100% recyclable bottles and caps, aligning their business practices with environmental responsibility.

Apart from the Temple facility, Niagara Bottling operates another bottling plant at Meadowville Technology Park in Chesterfield County, Virginia, further expanding its presence and impact within the beverage manufacturing sector.

As the expansion project takes shape, the city of Temple can anticipate economic growth, job creation, and enhanced opportunities for the food and beverage industry. Niagara Bottling’s commitment to sustainable practices also aligns with the growing consumer demand for environmentally conscious products. The company’s investment showcases their belief in the region’s potential and serves as a testament to the collaborative efforts between private enterprises and local authorities to foster economic development.

Overall, Niagara Bottling’s decision to invest in the expansion of its Temple facility reflects the company’s dedication to excellence, growth, and environmental stewardship.

With the added capacity, the company can further strengthen its presence in the region and meet the demands of its expanding customer base.Renewable Hydrogen Bottling

The partnership between Niagara and the Temple community is poised to yield long-term benefits, both economically and environmentally, solidifying Temple’s position as a hub for the food and beverage industry in the United States.

RockCreek’s Investment Advances Renewable Hydrogen and Sustainable Aviation Fuel Commercialization from Biomass and Waste

RockCreek, a prominent global multi-asset firm focused on investing in the energy transition, has recently closed an investment deal with Raven SR, Inc. (Raven SR), a company at the forefront of producing high-value renewable transportation fuels from various feedstocks, including waste streams, utilizing an innovative non-combustion process. This strategic partnership aims to accelerate the commercialization of low-to-negative carbon intensity hydrogen and sustainable aviation fuel (SAF) from biomass and waste, signaling a significant step towards decarbonizing the aviation and transportation industries.

According to Hydrocarbonprocessing, RockCreek’s investment will provide crucial financial backing for Raven SR to further develop and commercialize their groundbreaking technologies. The investment comes on the heels of the remarkable achievement by Raven SR’s Richmond, Calif. project, which recently became the first-ever biomass-to-renewable hydrogen project permitted in California. Starting from 2024, renewable hydrogen from this project will be readily available in the Bay Area through agreements with Chevron New Energies and Hyzon Motors.

Moreover, the same core technology will be adapted to facilitate the commercial production of sustainable aviation fuel by 2025. Renewable Hydrogen Bottling

RockCreek’s involvement in the Raven SR project is part of its Smart Aviation Futures fund, which strategically invests in high-growth companies that contribute to and benefit from the aviation industry’s decarbonization efforts. Recognizing the increasing importance of sustainable aviation fuel and hydrogen in the sector’s energy transition, the Smart Aviation Futures fund capitalizes on opportunities created by global policy measures like the U.S. Inflation Reduction Act. The fund aims to invest in companies aligned with both corporate and consumer preferences for reducing environmental footprints, as supportive public policy initiatives and growing demand for SAF continue to drive expansion and project development worldwide.

Justin Heyman, managing director of RockCreek, expressed enthusiasm about the potential impact of Raven SR’s products on the aviation and transportation industries’ decarbonization efforts. He highlighted that their renewable transportation fuels possess an attractive environmental footprint while remaining cost-competitive with traditional fuels, offering industries viable options to manage fuel costs and achieve emission reduction goals. Renewable Hydrogen Bottling

Matt Murdock, CEO of Raven SR, emphasized the significance of RockCreek’s investment in the company’s efforts to reduce carbon emissions through the production of carbon-neutral and carbon-negative fuels. Raven SR’s patented Steam/CO2 Reforming technology stands out as a non-combustion thermal, chemical reductive process capable of converting organic waste and landfill gas into hydrogen and Fischer-Tropsch synthetic fuels. Unlike conventional hydrogen production technologies, this innovative process does not require fresh water as a feedstock and consumes less than half the energy of electrolysis. Consequently, Raven SR can deliver fuels with low to negative carbon intensity, significantly contributing to sustainability goals.

A key aspect of Raven SR’s approach is its commitment to generating as much of its own power on-site as possible, reducing reliance on external grids. This emphasis on self-sustainability aligns with their modular design, which allows for scalable local production of renewable hydrogen and synthetic liquid fuels from locally-sourced waste, further promoting circular economy principles.

In line with the broader effort to provide practical solutions for cleaner energy, ECARU (Egyptian Company for Solid Waste Recycling), Qalaa Holdings, and Axens have also taken steps towards advancing cleaner energy solutions. These organizations recently signed a cooperation protocol in the presence of the French ambassador to Egypt, Marc Barety. The collaboration aims to conduct technical and economic studies for a second-generation biofuel (advanced bioethanol) and Sustainable Aviation Fuel (SAF) production project, reinforcing the global commitment to a sustainable energy future.

In conclusion, RockCreek’s investment in Raven SR represents a pivotal move in the journey towards commercializing renewable hydrogen and sustainable aviation fuel from biomass and waste. Renewable Hydrogen Bottling

The innovative technologies developed by Raven SR hold immense promise for decarbonizing critical industries while addressing environmental challenges. As the demand for sustainable aviation fuel and renewable hydrogen continues to surge, this strategic partnership stands as a beacon of progress in the global transition to cleaner and more sustainable energy sources.

Exploring the Principles of PID Controllers

Feedback loops have been used in self-regulating systems (otherwise known as the routing back of the output of a system to its input) for some years and have become an integral part of modern technology. James Clark Maxwell’s article, On Governors, was one of the earliest attempts to rigorously describe control loops using feedback.1

In the context of control strategies, an open-loop control system is the term given to a controller whose action is determined based on predetermined input values without considering feedback. Renewable Hydrogen Bottling

A closed-loop controller, in contrast, incorporates continuous feedback, facilitating real-time adjustments to enhance stability, precision, and robustness and ultimately making it more suitable to help attain the desired control objectives in changing conditions.

The most widespread type of closed-loop control system today is the Proportional–Integral–Derivative (PID) controller. The output of a system is continuously measured and adjusted by these types of controllers to match a desired setpoint, that is, a given target condition for the system or process under consideration.

PID controllers are extremely versatile, require little prior knowledge or model of the system, and are relatively cost-effective and straightforward to implement. This makes them ideal to implement in various systems: from pneumatics and hydraulics to analog and digital electronics.

For this reason, PID controllers have become extensively used in various industries and research applications, with uses in photonics, manufacturing, material science, sensors, and nanotechnology.

PID control loops are utilized in several aspects of industrial automation and everyday life, with uses ranging from ovens used for cooking food or samples, flow controllers in pipes, the gyroscopes found in self-navigating cars and smartphones, and even in the management of daily road traffic.

Along with this ubiquitous use, the presence of PID control loops can be noted in more advanced research fields as well: for instance, in closed-loop control of MEMS-based (micro-electromechanical systems) gyroscopes, in the stabilization of laser cavities and interferometers in photonics and optics, and in the characterization of mechanical resonators in scanning probe microscopy (SPM). Renewable Hydrogen Bottling

This article presents PID control loops’ fundamental principles and functions: outlining their strengths and limitations, analyzing their basic building blocks, and considering their tuning and designing strategies before detailing how they can be easily implemented with Zurich Instruments’ lock-in amplifiers.

PID Working Principle and Building Blocks

The principal goal of a PID controller is to produce a control signal that can dynamically minimize the difference between the output and the desired setpoint of a particular system.

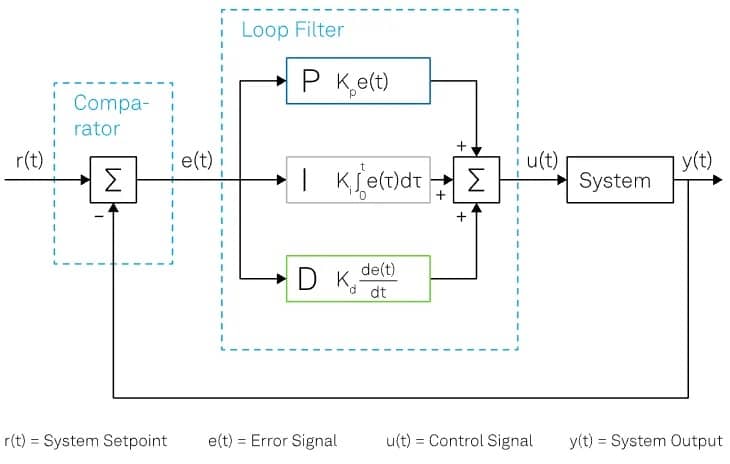

It is essential to reflect on the exemplary scheme shown in Figure 1. The output of the system y(t) is looped back and measured against the setpoint r(t) by the comparator as a first step, which generates the time-dependent error signal e(t) = r(t) – y(t).

The loop filter then minimizes this error signal and is subsequently used to generate the control signal u(t) that drives the system’s output, which initiates closed-loop operation. To minimize the error, these steps are continuously executed.

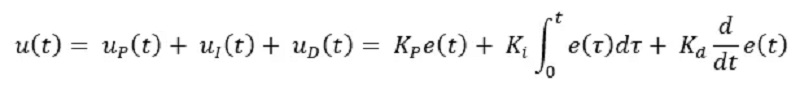

In addition to considering the current error, it is also important to consider both its accumulation over time (represented by the integral) and its future tendency (represented by the derivative at time t), as depicted in Figure 2.

In the most general case, error minimization is accomplished by means of the three primary components of the PID controller loop filter: the integral, proportional, and derivative terms. The complete control function in its most general form can mathematically be written as the sum of the three individual contributions:

where Kp, Ki and Kd are the gain coefficients linked to the proportional, integral, and derivative terms, respectively. Renewable Hydrogen Bottling

The proportional term is based on the current error between the setpoint and the measured output of the system and is denoted with P. This term applies a correction proportional to the amplitude of the error and helps to take the output of the system back to the setpoint, leading to a reduction of the rise time of the correction signal (as depicted in Figure 3).

The larger the error with a fixed Kp, the larger uP(t) – or, in other words, the larger the error, the larger the correction applied by the proportional term.

The P term cannot nullify the error by itself, as it always requires a non-zero error to generate its output. An equilibrium is reached in steady-state system conditions, which includes a steady-state error.

UNIFI®, Makers of REPREVE®, Affirms Environmental Benefits of REPREVE® Polyester in Updated Life Cycle Data

Unifi, a pioneering global textile solutions provider and the creator of REPREVE, the world’s leading recycled polyester fiber brand, has recently released the findings of an independent, peer-reviewed Life Cycle Assessment (LCA). The LCA validates that REPREVE recycled polyester significantly mitigates climate change potential when compared to virgin polyester.

REPREVE was conceived as a response to the mounting concern about plastic waste polluting our environment. It is produced from post-consumer plastic bottles and pre-consumer waste materials, making it a sustainable alternative to traditional polyester. The versatile REPREVE fibers and yarns are incorporated into various fabrics used in apparel, automotive interiors, home furnishings, and numerous other products, partnering with some of the most renowned brands worldwide. Renewable Hydrogen Bottling

The updated LCA was meticulously conducted to comprehensively assess the environmental impacts of REPREVE polyester across various categories and multiple global production sites, juxtaposed with virgin polyester produced in the same locations.

The key findings of the LCA underscore the significant environmental advantages of REPREVE polyester over its virgin counterparts:

- Greenhouse Gas Emissions: REPREVE polyester reduces greenhouse gas emissions by up to 42% compared to virgin filament yarn and an impressive 60% when compared to virgin staple fiber.

- Fossil Fuels Depletion: The LCA data shows a reduction of up to 66% in fossil fuel depletion relative to virgin filament yarn and an astounding 76% reduction when compared to virgin staple fiber.

- Water Scarcity and Freshwater Consumption: REPREVE polyester outperforms virgin filament yarn by reducing water scarcity by up to 76% and freshwater consumption by up to 67%.

Eddie Ingle, Chief Executive Officer of Unifi, Inc., emphasized that “REPREVE polyester provides an alternative to virgin fibers and yarns that reduces climate change potential and offers an immediate impact on the sustainability goals and environmental considerations of our esteemed partner brands that integrate REPREVE into their products. We strive to be great stewards for our planet and our future, and we are thrilled to be able to help others do the same.” Renewable Hydrogen Bottling

Meredith Boyd, Senior Vice President of Sustainability, Technology & Innovation at UNIFI, echoed the company’s commitment to transparency and traceability. Boyd stated, “It’s important for us to share our peer-reviewed LCA data to show the significant reductions that REPREVE polyester offers to critical environmental factors that otherwise accelerate climate change or deplete other limited resources.”

UNIFI, Inc., listed on the NYSE as UFI, has established itself as a global leader in manufacturing synthetic and recycled performance fibers. The company’s breakthrough technology, REPREVE, has repurposed over 35 billion plastic bottles into recycled fiber, which has been employed in new apparel, footwear, home goods, and various other consumer products. UNIFI continuously innovates its technologies to meet consumer demands in areas such as moisture management, thermal regulation, antimicrobial protection, UV protection, stretch, water resistance, and enhanced softness. Their collaborations with influential brands across industries like sports apparel, fashion, home, and automotive have further solidified their position in the market.

REPREVE, as a trademark of Unifi, Inc., is the global leader in recycled performance fibers, responsible for converting billions of plastic bottles into trusted recycled fiber that powers sustainable consumer goods worldwide. The fiber technology offered by REPREVE enhances comfort, performance, durability, thermal regulation, and more. Furthermore, REPREVE has received the U TRUST product verification, certifying transparency and traceability, and empowering brands and consumers to champion sustainability.

In an era where environmental preservation is paramount, REPREVE stands as a catalyst for change, driving the world towards a more sustainable future through continuous innovation and commitment to sustainability. Renewable Hydrogen Bottling

For further inquiries or information about REPREVE, visit their official website at www.repreve.com.

Media Contact: Kelly Gardiner Factory PR Email: repreve@factorypr.com

Alef Aeronautics’ Revolutionary Flying Electric Car Gains $750M in Pre-Orders, Set to Reach US Dealerships

Imagine walking into a car dealership and not just choosing a sleek electric car, but one that can take flight. The realm of science fiction is inching closer to reality as Alef Aeronautics makes groundbreaking strides with its flying electric car. Having secured legal approval for flight in the US, the company has now surpassed all expectations by opening pre-orders to sell these innovative modern aircraft through car dealerships for the first time.

Alef Aeronautics embarked on an ambitious journey in 2015, with a vision to redefine sustainable travel and create a drivable car capable of vertical takeoff and landing (eVTOL) while remaining affordable. To kick-start this ambitious project, the renowned venture capitalist, Tim Draper, who was an early investor in Tesla, provided $3 million in seed money, propelling the initiative forward. Renewable Hydrogen Bottling

Over the years, Alef Aeronautics relentlessly worked on their model, and the world was introduced to their groundbreaking achievement on October 19, 2022 – the first 100% electric flying car, named “Model A.” This innovative vehicle boasts a driving range of 200 miles and a flying range of 110 miles. Excitement peaked last month when the “Model A” received a Special Airworthiness Certification from the US Federal Aviation Administration, marking a significant milestone for the company.

Though the “Model A” is scheduled for production in the fourth quarter of 2025, its popularity is already soaring. Alef proudly announced that pre-orders for their flying electric car have reached an astounding 2,500 units, a considerable increase from the 400 pre-orders recorded at the end of the previous year. This overwhelming demand translates to an impressive $750 million in revenue once the deliveries commence.

Potential buyers have two pre-order options: they can either secure a spot in the regular queue by placing a $150 deposit or choose priority placement by paying $1,500. With 2,100 individuals and 400 businesses, including a California car dealership, already on board, Alef has achieved yet another milestone by becoming the first company in history to sell a modern aircraft through a car dealership.

Jim Dukhovny, Alef’s CEO, expressed his excitement at the significant demand, remarking on the notes of gratitude and inspiration they received from customers with their pre-orders. He emphasized the company’s commitment to realizing their vision of a world with airborne vehicles, echoing the iconic words from the film “Back to the Future”: “Where we’re going, we don’t need roads.” Renewable Hydrogen Bottling

The “Model A” is designed to carry one or two passengers, allowing them to drive on public roads and take off and land vertically. But Alef Aeronautics doesn’t plan to stop there; they have already set their sights on the next venture. After the “Model A,” the company intends to launch the “Model Z,” a four-person sedan expected to hit the market in 2035. The ambitious plan for this vehicle includes over 300 miles of flying range and a driving range of 220 miles, all at a starting price of $35,000.

Alef Aeronautics’ dedication to pushing the boundaries of modern transportation and sustainability is evident in their ambitious projects. Their flying electric cars not only represent a major step forward in the automotive industry but also offer a glimpse into the future of urban mobility. As the world eagerly awaits the realization of these groundbreaking vehicles, it’s evident that Alef Aeronautics is leading the way towards a new era of transportation that combines the thrill of flying with the environmental responsibility of electric mobility.

China, the Asian giant, is poised to make significant investments in the car world, causing ripples of concern in Europe

While Europeans may not immediately associate China with cars, the country has made remarkable strides in the automotive industry, particularly in the production of new generation cars, primarily focusing on electric and compact models that are affordable, not only for the domestic market but also for the global stage.

The Chinese automotive industry has grown exponentially, with China emerging as one of the world’s major producers and consumers of cars. To bolster its position further, the Chinese government has unveiled new measures to optimize and incentivize the purchase, use, and management of vehicles, particularly electric cars, with the ultimate goal of promoting sustainable development. Renewable Hydrogen Bottling

Recognizing the pressing need to address traffic congestion and pollution, China has put in place restrictions on car purchases in certain cities. However, in a strategic move, the government plans to increase annual quotas and expedite the scrapping of vehicles that fail to meet current emission standards. These measures aim to encourage the adoption of newer, eco-friendly models.

The Chinese government is also taking steps to facilitate the trade and registration of used vehicles while promoting the phasing out of older, less environmentally friendly cars from the market. To support the transition to electric vehicles, pilot projects will be initiated in the commercial vehicle sector, with a focus on establishing new recharging infrastructures, especially at bus stations, to encourage public transportation to embrace electric power.

Furthermore, the Chinese authorities are committed to reducing the costs associated with purchasing and operating hybrid and electric vehicles. One of the key areas targeted for improvement is electricity pricing, with the aim of lowering recharging costs and making electric cars more affordable and accessible to the masses.

To complement these efforts, the government has devised a credit support strategy to assist potential car buyers. Insurance for charging stations will be made available, and new rates and rules will be introduced to alleviate parking issues, with an emphasis on increasing available parking spaces in both urban centers and suburban areas.

Despite these ambitious plans to promote modern and eco-friendly vehicles, China is aware of the challenges that lie ahead, especially concerning traffic and parking management. Critics often cite the country’s major cities as examples of pollution, congestion, and chaos, and addressing these issues will be crucial to ensure the success of their automotive endeavors. Renewable Hydrogen Bottling

China’s commitment to pushing the adoption of electric and efficient vehicles marks a significant step in the right direction towards mitigating air pollution and reducing the environmental impact of transportation. However, it also signifies that China’s roads will witness a surge in the number of vehicles, leading to complex challenges in managing traffic flow and parking spaces.

While Europe may be apprehensive about China’s growing dominance in the car industry, it is evident that China’s investment in electric vehicles and sustainable transportation will have far-reaching implications for the global automotive market. As China continues to assert itself as a leader in the car world, European countries will need to adapt their strategies to remain competitive and contribute to the collective goal of a greener and more sustainable future for the automotive industry.

LyondellBasell, a major player in the polyolefins industry, has recently invested in a Dutch plastics reclaimer focused on producing HDPE and PP flakes

The company acquired a 50% stake in Stiphout Industries, which was founded in 2015 and has the capacity to recycle post-consumer plastics from approximately 500,000 individuals. Although the financial details of the investment were not disclosed, the move reflects LyondellBasell’s commitment to recycling and plastic waste processing companies that complement its existing assets in the Netherlands and Germany, in line with their integrated hub model. Renewable Hydrogen Bottling

This is not the first time LyondellBasell has made such an investment. In 2017, the company purchased a 50% stake in Quality Circular Polymers (QCP), another Dutch reclaimer, with the remaining half acquired by waste management giant Suez. Subsequently, in 2020, LyondellBasell and Suez jointly acquired the Belgian reclaimer TIVACO, integrating it into the QCP brand and expanding the recycling capacity of the operation.

In 2021, a significant development occurred when Veolia and Suez reached a merger agreement, and the Veolia name was retained for operations in mainland Europe. In April 2023, LyondellBasell further consolidated its position in the market by acquiring Veolia’s stake in QCP, thereby attaining 100% ownership of the reclaimer.

With the addition of Stiphout Industries to their portfolio, LyondellBasell envisions synergies with QCP in terms of logistics and operations. The collaboration opens up new possibilities for the expansion of their CirculenRecover portfolio, a collection of recycled-content plastics marketed under the Circulen brand, which includes recycled and “renewable-based” plastics. The company has set ambitious goals, aiming to produce and sell 2 million metric tons of Circulen polymers annually by 2030. However, it fell short of its interim target in the previous year, selling only 80,000 tons of Circulen polymers in 2022, while the goal was 150,000 tons.

To bolster their efforts in post-consumer plastics recycling, LyondellBasell intends to pursue joint ventures worldwide to establish more recycling capacities. In support of these endeavors and other sustainability projects, the company has issued half a billion dollars in green bonds.

The strategic investments made by LyondellBasell underscore the increasing importance of recycling in the plastics industry. By acquiring stakes in recycling and reclamation companies, the polyolefins producer not only strengthens its position in the market but also demonstrates its commitment to circular economy practices and low-carbon solutions. Such initiatives are crucial in addressing the environmental challenges posed by plastic waste and in achieving sustainability goals.

In conclusion, LyondellBasell’s recent acquisition of a 50% stake in Stiphout Industries and its previous investments in QCP and TIVACO reflect the company’s dedication to recycling and sustainability. The collaboration between these reclamation companies allows for synergies in operations and logistics, paving the way for further expansion of their recycled-content plastics portfolio. LyondellBasell’s commitment to producing and selling 2 million metric tons of Circulen polymers annually by 2030 demonstrates its ambitious goals in contributing to a circular and low-carbon future. Through strategic investments and the issuance of green bonds, the company aims to drive the development of post-consumer plastics recycling capacity and support other eco-friendly projects. Ultimately, these efforts signal a positive step toward a more sustainable and environmentally conscious plastics industry.