Post-consumer PET bottles – 2035 – Brussels Tightens Control on E-Fuels, Jeopardizing Exemptions 27-09-2023

Post-consumer PET bottles

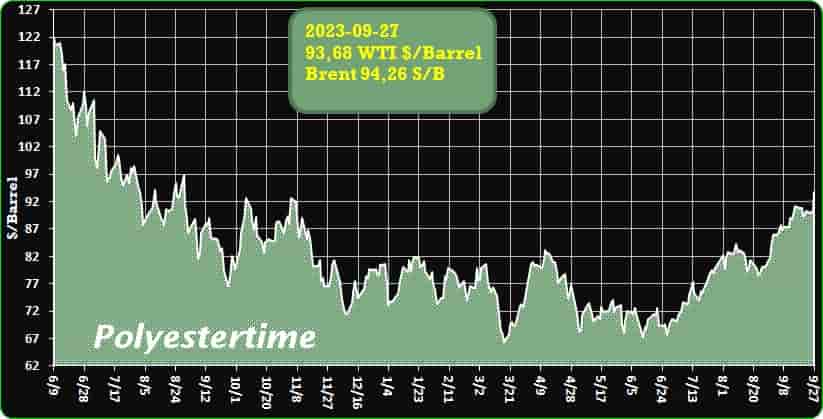

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

100 billion bottles recycled by Indorama

Indorama Ventures Public Company Limited, a global sustainable chemical company, today announces that it has recycled 100 billion post-consumer PET bottles since February 2011 1. This has diverted 2.1 million tons of waste from the environment and saved 2.9 million tons of carbon footprint from the product lifecycles. Demonstrating its commitment to support the establishment of a circular economy for PET, in the last ten years Indorama Ventures has spent more than $1 billion towards waste collection of used PET bottles.

Mr. Aloke Lohia, Founder and Group CEO of Indorama Ventures said, “As we mark the recycling of 100 billion PET bottles, we want to thank consumers for recycling, and global brand owners for using recyclable and recycled packaging while also increasing collection rates. The scale of the waste challenge requires us all to do more, faster. In March 2020, we announced achieving the milestone of 50 billion PET bottles recycled in nine years. Today we hit the 100 billion mark in three and a half years.”

“By recycling post-consumer PET bottles into new bottles, we give waste an economic value. Post-consumer PET bottles

This drives improvements in waste collection systems, meaning less waste and a cleaner environment. In the last 10 years we have spent more than $1 billion towards waste collection systems for used PET bottles. We pledge to continue our long-term focus on circularity.”

The company has also committed a further $1.5 billion to expand its recycling business. To support increased recycling rates globally, Indorama Ventures has expanded its recycling facilities, infrastructure, and public education programs. The unique PET plastic used in soft drinks and water bottles is fully recyclable and is collected in practice and at scale. As a result, PET is the most recycled plastic in the world, and the company’s recycling achievements support that. Building on its position as the world’s largest producer of recycled resin used in plastic beverage bottles, Indorama Ventures is also seeking advanced technologies to deliver more recycling infrastructure globally and reduce lifecycle carbon emissions. Post-consumer PET bottles

The company now has 20 recycling sites in Asia, the Americas, and Europe. Recent developments include doubling the capacity of a recycling site in Brazil; and the opening of PETValue, the largest bottle-to-bottle recycling facility in the Philippines, in partnership with Coca-Cola. Both part of a $300 million ‘Blue Loan’ Indorama Ventures received in 2020 from the International Finance Corporation (IFC), part of the World Bank, and Asian Development Bank. The loan has the objective of increasing recycling capacity and diverting plastic waste from landfills and oceans in Thailand, Indonesia, Philippines, India, and Brazil – countries seeking support in managing environmental waste.

Indorama Ventures has also partnered with the Yunus Foundation, a leading non-profit organization promoting sustainable development with a global network, with the goal of educating one million consumers globally about recycling by 2030, with 200,000 reached so far. Post-consumer PET bottles

Mr. Lohia added, “Sustainability is at the core of our company. These achievements reflect our commitment to environmental sustainability and our determination to establish a truly circular economy for PET packaging. Reaching this milestone is a testament to our planet’s growing commitment to sustainability. Each of these bottles represents a reduction in waste, and a step towards a world where no packaging ends up as litter or waste. This milestone achievement shows the positive change that can occur when we work together to support PET recycling and strive for a more circular world.”

BASF broadens its Monomers Portfolio and launches bio-based 2-Octyl Acrylate

- First commercial scale production of bio-based 2-Octyl Acrylate

- 14C content of 73% according to ISO 16620

- High performance and easy to use in a broad range of applications

Ludwigshafen, Germany – BASF is expanding its growing portfolio of 14C bio-based monomers with a proprietary process for production of 2-Octyl Acrylate (2-OA). The new product underlines BASF’s strong commitment to innovation for a sustainable future with 73% 14C-tracable bio-based content according to ISO 16620. Besides the regular 14C bio-based 2-Octyl Acrylate, BASF also launched the new product as 2-Octyl Acrylate BMB ISCC Plus. Here, the remaining carbon content is ISCC PLUS certified, and by applying BASF’s biomass balance (BMB1) approach, this variant offers a further reduced product carbon footprint (PCF2). Post-consumer PET bottles

With an industrial-scale production setup at its Verbund site in Ludwigshafen, Germany, BASF has a pioneering role when it comes to producing 2-Octyl Acrylate in large volumes. This allows BASF to make the bio-based monomer globally available as a raw material. “We have broadened our product portfolio to support customers on their sustainability journey. With 2-OA, we are proud to have launched a novel acrylic monomer that helps customers to meet their sustainability goals,” says Dr. Reiner Geier, Senior Vice President Industrial Petrochemicals Europe.

BASF’s 2-Octyl Acrylate uses 2-Octanol as the respective bio-based feedstock. This bio-alcohol is based on castor oil, a sustainable non-edible feedstock which is reliably available throughout the year.

With its balanced solvency, 2-Octyl Acrylate can easily be used as bio-based alternative to fossil-based monomers such as 2-Ethylhexyl Acrylate (2-EHA) and n-Butyl Acrylate (BA) e.g. in adhesives formulations, or coatings applicationsPost-consumer PET bottles

The new product also offers performance benefits compared to fossil alternatives, showing improved scrub resistance in coatings, shear resistance in adhesives and excellent weatherability. Therefore, 2-Octyl Acrylate is one of the few 14C bio-based monomers which can be used in both standard and high-performance applications. The high purity of BASF’s 2-Octyl Acrylate provides a reliably high quality, with low volatile organic compounds (VOC) and enables customers to use the monomer in a broad application range.

BASF’s 2-Octyl Acrylate is already registered in the EU, the US, Japan and many other countries. Further registrations are ongoing. Post-consumer PET bottlesBottles recycled

Trade between China and Russia continues to surge in 2023, maintaining the robust momentum that was established in the record-breaking year of 2022

The Russian Customs Service has reported substantial growth in both exports and imports between the two nations since the beginning of this year.

According to the Russian Customs Service’s Telegram channel, bilateral trade between Russia and China has witnessed a remarkable 25% increase from January to August compared to the previous year. Data from China’s customs agency supports this, indicating that trade turnover during this period reached an impressive $155.1 billion.

Furthermore, the Russian customs authority has expressed the intention of Moscow and Beijing to further facilitate customs procedures in order to enhance trade. They have a particular interest in ensuring the continuous, round-the-clock operation of key transport hubs, such as the Zabaikalsk-Manzhouli automobile border-crossing checkpoint and the Pogranichny-Suifenhe road crossing. Post-consumer PET bottles

Russia primarily supplies China with energy resources, including oil and gas, as well as refined products, agri-food items, and industrial goods. In contrast, China exports a wide array of products, encompassing foodstuffs, equipment, mobile phones, electronics, engineering goods, furniture, toys, textiles, clothing, and footwear.

Notably, trade between Russia and China reached an unprecedented pinnacle of $190.3 billion in the preceding year. The two nations are now on track to surpass their $200 billion target for this year, firmly believing that achieving an annual trade volume of $250 billion is entirely feasible.

The strengthening of economic ties between Russia and China is bolstered by their shared commitment to conducting a significant portion of transactions using their respective national currencies, reducing their reliance on the US dollar. Moscow and Beijing have redoubled their efforts to lessen their dependence on the dollar and euro in global trade, particularly in light of Western sanctions imposed on Russia and the ongoing trade dispute between the US and China. Post-consumer PET bottles

2035 – Brussels Tightens Control on E-Fuels, Jeopardizing Exemptions

The European Commission is poised to unveil its inaugural proposal regarding exemptions for e-fuels as an addendum to the legislation prohibiting the sale of new gasoline and diesel vehicles by 2035. However, the forthcoming document exhibits notably stringent restrictions: synthetic fuels must achieve complete carbon dioxide neutrality, necessitating the capture of an equivalent amount of CO2 from the atmosphere as that emitted by engines during operation to qualify for exemption. This objective is perceived as nearly unattainable by the automotive industry, which is already engaged in a vigorous debate.

This Commission’s requirement exceeds the stringency of other community regulations. For instance, member states striving to fulfill renewable energy targets can utilize specific fuels with a 70% reduction in emissions rather than the 100% stipulated for e-fuels. Consequently, e-fuels may once again become a contentious issue, reminiscent of the February episode when Germany impeded the directive on phasing out internal combustion engines, staunchly advocating for a synthetic fuel exemption. Post-consumer PET bottles

Consequently, a tug of war is inevitable; the Commission’s proposal must undergo negotiation with other European institutions, including the Parliament and Council, which may result in significant changes in the months ahead. A consensus must be reached by year-end.

Amidst this, the eFuel Alliance accuses the Commission of reneging on its commitment to include the e-fuel exemption, asserting that the proposal’s restrictions render it practically unworkable. This has unveiled an internal conflict between the Directorate-General for Climate Action (DG Clima) and the Directorate-General for Internal Market (DG Grow). The latter had sought alignment of the e-fuel definition with the Renewable Energy Directive (RED), which mandates a 70% reduction in CO2 emissions for non-biological renewable fuels compared to traditional fuels. Ultimately, DG Clima prevailed, establishing the percentage at 100%. Post-consumer PET bottles

Ralf Diemer from the eFuel Alliance emphasizes, “E-fuels, when produced from renewable sources, achieve climate neutrality, emitting only the CO2 captured during production during combustion.” RED accounts for not only the vehicle’s usage phase but also factors like transport, storage, and fuel distribution, making a 100% reduction in emissions nearly unattainable. This concept applies to all technologies, including electric mobility. The Commission’s choice of 100% lacks a clear basis, and there is no impact assessment outlining how and when this objective can be realized. To assess a product’s actual CO2 emissions, a comprehensive life cycle analysis is crucial.

Diemer concludes, “We support the EU’s intention to consider the lifecycle more comprehensively, even though this approach has not been widely implemented in many other regulations. However, the industry needs intermediate steps to achieve climate neutrality goals. European legislators seem to be setting conditions that are more suitable for a world beyond 2040. Post-consumer PET bottles

The Commission’s current regulatory stance, already excessively stringent, impedes our objectives rather than fostering ambitious progress.”

SKC to build bioplastics plant in Vietnam

South Korea’s advanced materials maker SKC said Monday that it had decided on a location in Vietnam’s northeastern city of Hai Phong to establish a manufacturing plant for biodegradable plastics, as it pushes to expand its eco-friendly business.

Amid mounting global calls to reduce plastic waste, the international market size for bioplastics is expected to grow at an annual rate of over 20 percent.

SKC and its joint venture Ecovance officials and top executives visited Vietnam on Friday to attend a ceremony marking the launch of the investment plan, during which they received an investment registration certificate from the Vietnamese government, the legal document needed for overseas companies to invest in the country.

The factory, set to be operational in 2025, aims to generate an annual output of 70,000 tons, the largest scale in the world, of polybutylene adipate terephthalate or PBAT, a biodegradable co-polymer. Post-consumer PET bottles

High-strength PBAT has been independently developed by Ecovance by using cellulose extracted from trees. It boasts enhanced durability compared to conventional PBAT, facilitating commercialization and its extensive use in general-purpose plastics, from industrial films and food containers to diapers and masks.

Additionally, SKC will be building a separate facility at the same site to produce an annual 36,000 tons of a biodegradable material named Limex .

Limex is made by mixing limestone with plastic resins, such as polyethylene and polypropylene, to reduce the use of plastics in the manufacturing process. SKC seeks to commercialize biodegradable Limex made of its high-strength biodegradable PBAT which decomposes more quickly in nature. Post-consumer PET bottles

Europe Faces a Major Challenge in Exporting Electric Cars

As of January 1st, 2024, the cost of exporting electric cars from Europe to the United Kingdom will increase by 10%, prompting manufacturers to seek intervention from European authorities. Amid the ongoing issue of an influx of Chinese electric cars into the European market, Europe is now bracing itself for another challenge – the export of its electric vehicles to the UK.

In accordance with the provisions established during the lengthy and intricate post-Brexit negotiations, a new directive stipulates that, starting from January 1st, 2024, all electric vehicles traversing the English Channel in both directions must contain a minimum of 45% of their components sourced from either the EU or the United Kingdom, with batteries accounting for 50-60% of this requirement. Failure to meet these criteria will result in a 10% customs duty. Post-consumer PET bottles

Regrettably, as of now, no electric vehicle model complies with this directive, and time is rapidly dwindling.

Faced with the prospect of having to increase the prices of their electric cars, the European Association of Automobile Manufacturers (Acea) has issued an urgent plea to both the European Union and the United Kingdom to extend the deadline, aiming to avert further complications in an already challenging market.

Failure to act by the European Commission will result in a 10% tariff being imposed on EU electric vehicle exports to the UK, a critical trading partner. This could potentially cost EU vehicle manufacturers a staggering €4.3 billion over the next three years and may lead to a reduction in electric vehicle production by approximately 480,000 units, equivalent to the output of two medium-sized car factories, as indicated in the association’s press release.

The sole means of evading these tariffs would be to source all battery components and certain vital battery materials from the EU and the UK, a solution that is currently unfeasible. Post-consumer PET bottles

Increasing consumer prices for European electric vehicles, particularly during a time when gaining market share is fiercely competitive on the global stage, is an unfavorable course of action from both commercial and environmental perspectives. This approach risks ceding market share to global manufacturers. Europe should support its automotive industry in the transition to zero emissions, akin to other regions, rather than impeding its progress,” emphasized de Meo. The solution is straightforward: extend the existing phase-in period for battery regulations by an additional three years. We urge the Commission to make the right choice.

EV Car

Galp and Mitsui to invest $638m in biofuels and green hydrogen

The partnership will invest approximately $691m in two industrial-scale projects for renewable diesel and sustainable aviation fuels.

The project aims to replace around 20% of existing grey hydrogen consumption at the Sines refinery with low-carbon green hydrogen. Credit: odecam via Shutterstock.

Portuguese energy company Galp on Monday confirmed plans to enter into a joint venture (JV) with Japan-based trading company Mitsui to produce renewable diesel and sustainable aviation fuel (SAF) biofuels. Post-consumer PET bottles

The partnership will invest approximately $691m in two industrial-scale projects; a 270 kilotonnes per annum (ktpa) advanced biofuels unit and 100MW of electrolysers for the production of green hydrogen. Both units are expected to begin production during 2025. Galp will own 75% of the JV’s shares, with Mitsui owning the remaining 25%.

The advanced biofuels unit, which will receive approximately $425m in initial funds, will use waste residues feedstock from used cooking oil or animal fat to produce renewable diesel, also known as hydrotreated vegetable oil (HVO). SAFs will also be produced in the same way as the companies look to invest in the decarbonisation of the global travel sector. Post-consumer PET bottles

HVO can be used as an alternative to fossil diesel fuel for vehicles with internal combustion engines, with SAF increasingly being used as a lower-carbon alternative to jet fuel in aircraft. Both are environmentally friendly fuels with lower greenhouse gas emissions. Demand for HVO and SAF is expected to grow, especially in Europe where policies to encourage the use of biofuels are introduced.

PET plastic – “The Hidden Risks of Sunlight on Plastic Water Bottles” 26-09-2023

Post-consumer PET bottles