Textile-to-textile

Renewcell Expands The CIRCULOSE® Supplier Network To 116 Members, Increasing The Marketplace For Textiles Made With CIRCULOSE®

Renewcell, featuring textile-to-textile recycling at scale, announces the expansion of the CIRCULOSE® Supplier Network (CSN) to 116 members, marking a significant milestone in the journey toward a circular textile industry. This expansion brings an infusion of innovation, diversity, and global reach, increasing the number of materials made with CIRCULOSE® that are available to source now.

The CIRCULOSE® Supplier Network, initially composed of 47 yarn and textile producers, has now evolved to include a diverse range of 116 members. Particularly of note is the geographical expansion, with new members joining from regions such as Vietnam, Taiwan, and the Czech Republic. Textile-to-textile

The extension into the Southeast Asian region reaffirms Renewcell’s commitment to advancing circular fashion on a global scale.

In addition to the geographic diversification, this growth includes onboarding a dozen knitters and more than thirty yarn spinners, enhancing the variety of qualities made with CIRCULOSE® that are available for all brands to source. This expansion signifies a considerable step forward in ensuring that brands worldwide have access to a wide array of materials made with CIRCULOSE®.

A significant development within this expansion is the inclusion of home textile suppliers for the first time, including Sharadha Terry Products, The Kadri Mills, and Yang Tsu. This strategic addition opens up new possibilities for integrating CIRCULOSE® into various facets of the textile industry, reaffirming the network’s adaptability and potential.

Patrik Lundström, CEO at Renewcell, emphasizes the importance of this expansion: “The CIRCULOSE® Supplier Network plays a pivotal role in scaling up the availability of yarns and fabrics made with CIRCULOSE®. With a more diverse network across the textile supply chain, fashion brands now have a broader range of sustainable options to incorporate CIRCULOSE® into their designs.” Textile-to-textile

“Right now, Sustainability is not just a trend. It’s our need to make the future green,” states Shakaib Nazim, General Manager Marketing at Indigo. “Indigo Textile mill isn’t just a place of production; it’s a hub of innovation for sustainable denim. Our CIRCULOSE® denim fabric range is the perfect fit for style and sustainability. Our next step towards sustainability growth is to convert our core line fabrics with CIRCULOSE® fiber.”

Hatice Ates, Product Design and Development Manager at Ekoten, explains, “At Ekoten Fabrics, we are aware that circularity is the key to the fashion industry’s fight against climate change. We believe that the circularity of the fashion industry will be achieved through timeless designs and sustainable material selection. In this direction, we attach great importance to the use of cellulosic raw materials from secondary raw materials with low environmental impact.

We are delighted to join the CIRCULOSE® Supplier Network, which carries out disruptive innovation endeavors in this field.” Textile-to-textile

More…

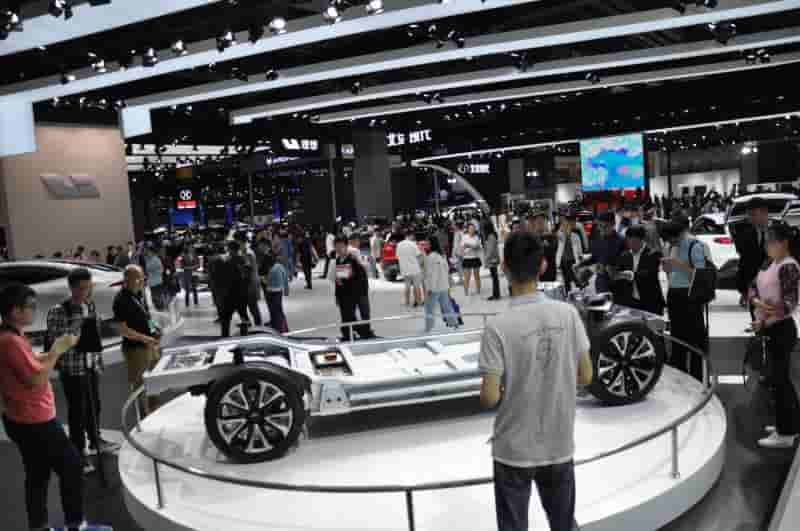

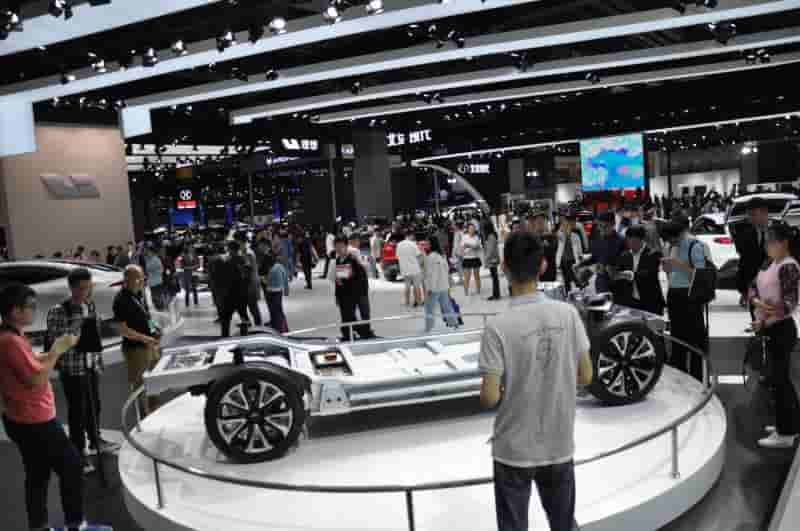

Europe has the evidence: China violates the rules on electric cars

Chinese electric cars receive subsidies from the People’s Republic of China, in violation of European Union rules.

Announced a few weeks ago by the President of the European Commission, Ursula von der Leyen, the anti-subsidy investigation into electric vehicles from China has already yielded initial results.

And the situation revealed is what many had suspected: Chinese electric cars benefit from subsidies from the People’s Republic.

This operation violates the European article for “defense against subsidized imports from non-European Union countries.” Textile-to-textile

Here is the evidence: In the document published on the official website of the European Commission, the evidence supporting the thesis is outlined:

• Direct transfer of funds and potential direct fund transfers or bonds.

• Waiver by the public administration of otherwise due revenues or non-collection of the same.

• Provision of goods or services by the public administration for a consideration lower than the appropriate amount.

Additionally, as reported by the European Commission, “various subsidies, loans, export credits, and lines of credit granted by state-owned banks” are added to these elements.

In summary: the Chinese government subsidizes its manufacturers, economically incentivizing them through favorable loans, minimal or even absent taxation, to export their electric cars. Textile-to-textile

An Urgent Issue “These subsidies have allowed a rapid increase in the market share of subsidized imports in the EU, to the detriment of the Union’s industry,” the document states, emphasizing how Chinese policies are creating an unfair competitive situation, threatening manufacturers in Europe.

Indeed, pricing is one of the key issues in the global automotive transition, with prices higher than those of conventional models but artificially lowered by the People’s Republic. The evidence available to the Commission also indicates that subsidized import prices are significantly lower than those of the Union’s industry, to the extent that they exert downward pressure on prices or prevent price increases that would otherwise have occurred, consequently putting significant pressure on sales, market shares, and profit margins of the Union. Textile-to-textile

This is particularly important in a context where the Union’s industry will need to achieve higher sales volumes in the battery electric vehicle market to absorb the substantial investments it must make to remain competitive in the transition to full electrification.

The increased imports of low-priced battery electric vehicles originating from the People’s Republic of China, capturing significant shares of a growing market, would result in heavy losses for the Union’s industry, which could quickly become unsustainable.

Tariffs on the Horizon? The evidence gathered so far does not conclusively resolve the issue, with investigations and discussions expected to continue for some time.

According to European regulations, the maximum limit is set at 13 months, meaning that any conclusions must be presented by the beginning of November 2024.

However, the European Union can begin taking action earlier: according to Union regulations, protective market measures can be implemented within nine months. In other words: customs tariffs. Textile-to-textile

By doing so, the gap between European and Chinese models would be narrowed, with the latter subject to higher taxes to offset the tax breaks and economic benefits granted by the People’s Republic.

DeltaMax performance modifiers help balance melt flow, impact strength, and stiffness to increase overall performance and enable wider recycled polypropylene (rPP) use.

Using Milliken’s Millad NX 800 ECO allows brands to display the Underwriters Laboratories (UL) label, indicating that the injection molded clarified PP part used, on average, 10% less energy during production.

The Hyperform line is certified by UL to enable 5% to 8% energy savings when used as a nucleator for thin-wall injection-molded PP containers.

Using UltraGuard Solutions ultimately helps designers create more mono-material products to improve end-stage recyclability Textile-to-textile

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20231005188625/en/

DeltaMax performance modifiers help balance melt flow, impact strength, and stiffness to increase overall performance and enable wider recycled polypropylene (rPP) use. (Photos © 2023 Milliken & Company)

Fortified and enhanced by Milliken’s innovative portfolio, plastics can take on performance-driven characteristics like increased clarity and strength and improved recyclability and emissions reductions, while supporting inter-material replacement opportunities and enabling recycled content utilization during production. Brands and manufacturers can also harness tangible gains from utilizing Milliken’s additive portfolio that help advance their own sustainability goals and metrics. These benefits align with Milliken’s enterprise-wide sustainability goals, including contributing to plastics end-of-life solutions, and reinforce Milliken’s path to achieving its SBTi-verified near- and long-term net-zero targetsSBTi-verified near- and long-term net-zero targets. Textile-to-textile

“As experts in the field of additive and colorant technologies, Milliken is uniquely positioned to help further the circular economy for plastics with a range of solutions that promote reduction, reuse, recycling and replacement strategies—solutions that very much align with Milliken’s overarching sustainability commitment,” shared Wim Van de Velde, global vice president of plastic additives for Milliken.

ArabPlast attendees can explore Milliken’s leading clarifier, modifier and additive products, including:

- Millad® NX® 8000 ECO, a clarifying agent for polypropylene (PP) that boosts clarity, enables faster production rates and reduces energy use. This product is certified by Underwriters Laboratories (UL) to provide average energy savings of 10% for the production of injection molded clarified PP parts.

- Hyperform® HPN®, performance additives for PP, deliver an improved balance in stiffness and impact-resistant properties while reducing energy use. The Hyperform line is certified by UL to enable 5% to 8% energy savings when this product is used as a nucleator when producing thin-wall injection-molded PP container lids and similar PP applications. Textile-to-textile

- DeltaMax®, performance modifiers for virgin and recycled PP, is unique in its ability to balance melt flow, impact strength, and stiffness to increase overall performance. DeltaMax helps converters reduce energy by running machines with faster cycle times or lower temperatures.

- DeltaFlow™ Viscosity Modifiers are solid concentrates designed to specifically help PP recyclers by increasing the melt flow rate of recycled polypropylene (rPP) for extrusion and injection molding processes.

- UltraGuard™ Solutions are concentrates that improve barrier properties in polyethylene (PE) to enable downgauging for reduced material usage and part weight, allowing designers to create more mono-material products to improve end-stage recyclability. Textile-to-textile

“We are a technology leader in the plastics ecosystem,” added Van de Velde. “But we understand the importance of collaboration to achieve critical sustainability milestones, which is why we’re working within the industry to envision the future of circular plastics.”

More…

Leaders from revalyu Resources, Heraeus Group, and the Development Authority of Bulloch County were joined by state and local officials to celebrate revalyu breaking ground on their first advanced PET (polyethylene terephthalate) recycling facility in America located at Gateway Regional Park in Statesboro, GA. revalyu is investing over $200 million to build a plant capable of recycling 200 million pounds (90,000 metric tons) of post-consumer PET plastic a year.

Customer applications have shown that the quality of recycled PET from plastic bottles is equivalent to that of virgin PET and can be used as a direct replacement. Once converted into high quality recycled PET, revalyu’s rPET chips can be used to produce any kind of sustainable PET product. Textile-to-textile

Currently, it is mostly used in the textile industry for applications such as seamless knitting, weaving, denim, automotive, furniture or technical textiles.

revalyu has already recycled over 6 billion bottles in India. Due to its unique recycling process based on glycolysis, the quality of revalyu’s rPET (recycled PET) products enables its customers to replace conventional oil-based PET with revalyu’s more sustainable rPET. Compared to conventional PET, revalyu’s rPET is produced using 75% less water, 91% less energy, and saves around 0.7 barrels of oil and 0.2 cubic meters of landfill space per 2000 pounds of PET recycled.

According to Jan van Kisfeld, Managing Director of revalyu, the company plans to recycle the equivalent of 25 million plastic bottles per day at its Georgia facility. He noted that, “Our first plant in the US is a very important step for the global expansion of our company. Our existing and future US customers have a huge demand for our 100% recycled pellets, which are equivalent in quality to conventional oil-based PET pellets. This advanced recycling plant will serve our customers directly from the US, enabling quicker transportation time, lower cost and a smaller CO2 footprint.” Textile-to-textile

Dr. Vivek Tandon, Founder of revalyu states: “Used PET plastic can now be efficiently, profitably and easily recycled again and again without degradation of quality. Our already commercialized revolutionary process will transform the PET plastic industry as we know it. In the years to come, less and less PET will be manufactured from oil as it is replaced by high quality recycled material. I thank Bulloch County for their incredible support, we could not have chosen a better partner for our international expansion.”

Lanxess Mesamoll plasticizer made more sustainable

Reduces carbon footprint; no impact on product quality

Sustainability, plasticizer, plastics, Mesamoll, sustainable raw materials, reduced product carbon footprint, PCF

In an important step towards more sustainability in its plasticizer portfolio, specialty chemicals company Lanxess‘ polymer additives (PLA) business unit now offers a more sustainable solution for its plasticizer Mesamoll. The phthalate-free, well-gelling and saponification-resistant plasticizer can be applied for a wide range of polymers, such as PVC, PUR and rubber. Textile-to-textile

“The switch to a more sustainable raw material base in the production of Mesamoll is a testament to Lanxess’ commitment to sustainability,” says Karsten Job, head of the Polymer Additives business. “Helping our customers to reduce their carbon footprint while meeting the demands of our customers for phthalate-free, reliable, and performing solutions makes us a front-runner in the market.”

In the future, more than 30% of the input materials for Mesamoll will come from fully sustainable sources resulting in a reduction in the product carbon footprint (PCF) of around 20%. As this is calculated via the mass balance approach by the supplier of the respective raw materials, there is no impact on the product quality or performance of Mesamoll.

“We want to actively shape the transformation of our industry,” says Stefan Tiebach, Head of Global Marketing at PLA. “At Lanxess, we firmly believe in leading by example and that is why we decided to stop the distribution of our conventional Mesamoll and are solely distributing the more sustainable version starting on 1 October, 2023. Our customers will continue to receive the usual product quality with the additional benefit of an improved sustainability profile.” Textile-to-textile

Lanxess says it is committed to further reduce the PCF for its plasticizer Mesamoll in the future, even though the current, reduced PCF is significantly lower than most alternative plasticizers on the market.

Lanxess is a specialty chemicals company with sales of 8.1 billion Euros in 2022. Its core business is the development, manufacturing and marketing of chemical intermediates, additives and consumer protection products.

The impact, resilience, and growth of responsible packaging in a wide region are daily chronicled by Packaging South Asia.

A multi-channel B2B publication and digital platform such as Packaging South Asia is always aware of the prospect of new beginnings and renewal. Its 16-year-old print monthly, based in New Delhi, India has demonstrated its commitment to progress and growth. The Indian and Asian packaging industries have shown resilience in the face of ongoing challenges over the past three years. Textile-to-textile

As we present our publishing plan for 2023, India’s real GDP growth for the financial year ending 31 March 2023 will reach 6.3%. Packaging industry growth has exceeded GDP growth even when allowing for inflation in the past three years.

The capacity for flexible film manufacturing in India increased by 33% over the past three years. With orders in place, we expect another 33% capacity addition from 2023 to 2025. Capacities in monocartons, corrugation, aseptic liquid packaging, and labels have grown similarly. The numbers are positive for most of the economies in the region – our platform increasingly reaches and influences these. Textile-to-textile

More…

Partnership previews upcoming sustainable packaging to enable circular economy at PACK EXPO Las Vegas 2023.

Accredo Packaging, a member of the API Group, and Presto Specialty Products, a business unit of Reynolds Consumer Products, came together to create the Child Guard flexible package for retailer Costco’s signature Kirkland Ultra Clean laundry detergent in the midst of the COVID-19 pandemic, which won the 2023 Gold Sustainability award from the Flexible Packaging Association. Textile-to-textile

At PACK EXPO Las Vegas 2023, the companies previewed a post-consumer recycled (PCR) edition of the Child Guard that has since launched.

The PCR Child Guard is made up of at least 25% PCR materials. The closure is opened by pressing down into a small notch with the mechanism. Pressing down on any other section of the zipper, the flexible pouch will remain closed.

“The level of recycled content inside the zipper helps to enable higher recycled content in the overall structure because it’s all done by weight. We are really excited about the partnership with Presto on that specific and we’ve got some exciting things on the horizon,” says Jonathan Quinn, vice president of marketing and sustainability at Accredo, a vertically integrated converter with a strong focus on sustainability.

Presto’s Fresh-Lock+ is also releasing a new line of closures made from bio-based materials, originating from sugar cane, which absorbs carbon during its growth cycle. These closures can be processed and recycled in the recyclable recovery stream.

More…

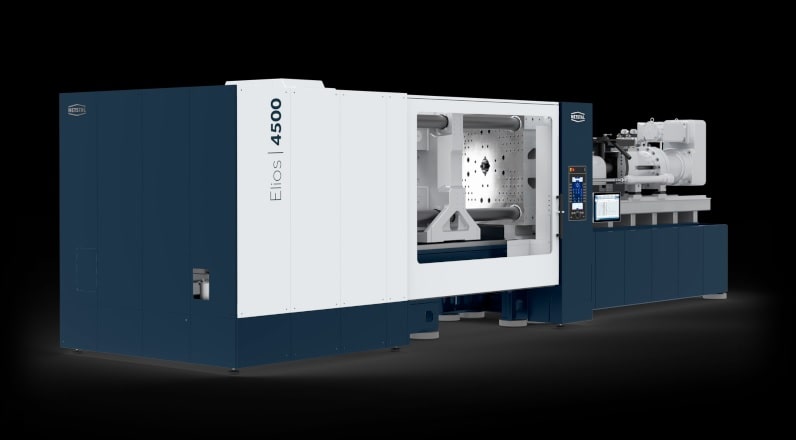

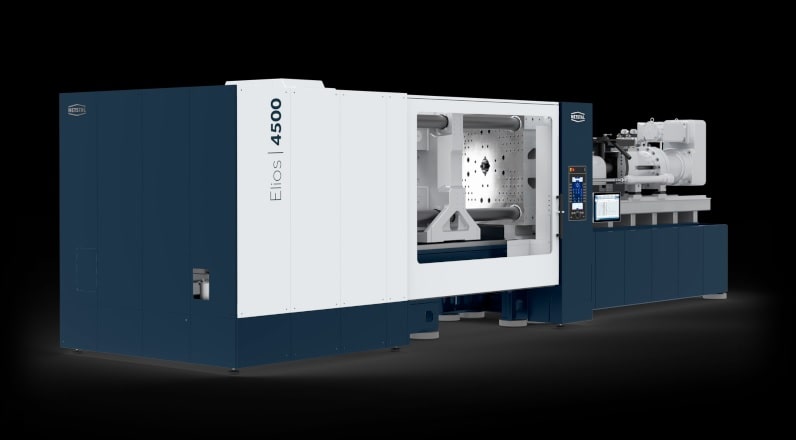

Shortly before Fakuma in Friedrichshafen, Germany, Netstal is presenting itself with a new brand identity. The company has defined the values ‘Leading, Reliable and Value-creating’ as the core of the corporate brand. With a contemporary corporate design, this positioning is intended to be communicated to the outside world.

The self-formulated mission is to sustainably maximise the added value of customers from the strategic application fields of thin-wall packaging, closures, PET preforms and medical technology. Textile-to-textile

With the new message to the target groups ‘Your best choice’, Netstal also hopes to address new target groups: “Today the shortage of skilled employees is an urgent challenge. More than ever, we want to present ourselves as an attractive employer, retain existing employees and attract new talent,” emphasises Renzo Davatz, CEO of Netstal and member of the KraussMaffei Executive Board.

New logo, new homepage

The heart of the new corporate design is the graphically revised company logo. “In modernizing it, we have been careful to respect Netstal’s long tradition. Clearly recognizable remains the familiar diamond shape, which has been opened up on the sides and forms a harmonious frame for the lettering,” says Michael Birchler, Head of Marketing and Communications at Netstal. “In a figurative sense, this also says that we are opening ourselves up to new opportunities and challenges. These include topics such as digitalisation and sustainability or the conscious use of the valuable plastic material. At the same time, we remain true to our core competence, and that is the injection moulding machine,” adds Renzo Davatz. Textile-to-textile

On the new Netstal website, customers, partners, and job seekers can gather information and get in touch with the company. In the new download centre, technical data is available for all current series of Netstal injection moulding machines. With user-oriented filter options, the selection can be narrowed down according to application area, drive technology, shot weight and tie-bar distance. The data sheets are available for download with either metric or imperial units of measurement. “We want to reduce hurdles and provide our customers and interested parties with the best possible support in the planning phase. That’s why we are also opening in this regard and making the required data freely available on the internet,” explains Wolfgang Zangerle, Head of Business Intelligence at Netstal.

Injection moulding machines reflect the new look

With the switch to the latest Axos 9 controller generation, Netstal has also applied its new corporate design to the current machine portfolio. The dominant colours of the covers are dark blue and white. Three-dimensional logos in chrome steel look has been designed to emphasise high quality and independence. Large window areas continue to provide insights into the inner workings of the clamping units of the machines, all of which are equipped with toggle lever technology. Textile-to-textile

More…

Plastic Pyrolysis Oil – Microban Launches Ascera™: A Patent-Pending, Cutting-Edge Antimicrobial Technology Inspired By Nature 06-10-2023

Textile-to-textile