Castor Oil – PLA-nonwovens – Textiles 15-04-2023 - Arhive

Castor Oil – PLA-nonwovens – Textiles

-Castor Oil-Based Biopolymer Market Grow Immensely at a CAGR of 16.06% to 2031

Companies covered in this report are Cargill Inc., BASF SE, Bio-Kleen Products, Inc., Balfour Beatty PLC, DuPont Industrial, Arkema, Evonik Industries AG, BASF SE, EMS-Chemie Holding AG, Solvay S.A

Jersey City, NJ, April 12, 2023 (GLOBE NEWSWIRE) — InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the “Global Castor Oil-Based Biopolymer Market Size, Share & Trends Analysis Report By End-User (Automotive, Solar, Household Appliances, Textile, Oil And Gas), Polymer Type (Bio-Polyamides (Bio-Polyamide 6, Bio-Polyamide 10 And 11), Bio-Polyurethane) And Foam (Pellets, Yarns)- Market Outlook And Industry Analysis 2031”

The global castor oil-based biopolymer market is estimated to reach over USD 3140.03 million by 2031, exhibiting a CAGR of 16.06% during the forecast period.

Castor oil and its derivatives are multifunctional compounds widely utilized in producing paints, lubricants, coatings, cosmetics, medicines, and other goods. These derivatives are gaining prominence due to their superior chemical characteristics. Major ingredient manufacturers are introducing castor oil-based compounds to capitalize on green chemical market prospects. Castor Oil – PLA-nonwovens – Textiles

Furthermore, increased research and development activities and increased investment are predicted to improve castor oil-based biopolymer market development. Because of outstanding properties such as being a very breathable, ultra-light, and super stretch product, the use of bio-polyamides in various apparel companies is gaining traction.

Additionally, the global castor oil-based biopolymer market growth is likely to profit from the expanding home appliances industry in developing nations due to rising disposable income and an increase in nuclear families, among other factors.

-NatureWorks introduces new Ingeo biopolymer solution for improved softness and strength in biobased nonwovens for hygiene applications

Delivering enhanced fluid management, improved tensile strength and up to 40% increase in softness offering a better performing spunbond nonwoven that minimizes converting challenges while providing a 62% smaller carbon footprint

Leading biopolymer and polylactic acid (PLA) manufacturer NatureWorks has further expanded the performance attributes delivered by Ingeo biopolymer in hygiene applications with the introduction of Ingeo 6500D for nonwovens. The new Ingeo solution offers increased softness and strength as well as improved fluid management when combined with optimized hydrophilic surface finish technology.

As a certified renewably sourced, low carbon and biobased material, Ingeo 6500D also meets the growing demand from brands and consumers for products made from more sustainable materials. Castor Oil – PLA-nonwovens – Textiles

“Building on our expertise in biobased nonwovens, we developed a product that, based on our rigorous testing, can improve the softness of spunbound nonwovens by 40% over nonwovens made with generic PLA”

“Building on our expertise in biobased nonwovens, we developed a product that, based on our rigorous testing, can improve the softness of spunbound nonwovens by 40% over nonwovens made with generic PLA,” says Robert Green, VP of Performance Polymers, at NatureWorks. “The tensile strength of the new Ingeo solution offers improved processing for converters offering efficient low basis weight fabric production on the latest generation of spunbond equipment. We are looking forward to collaborating with the supply chain as we continue development of this new Ingeo solution in nonwoven applications including diapers and wipes.”

When combined with tailored topical treatments developed in partnership with fiber lubricant manufacturer Goulston Technologies, the result is lighter, thinner absorbent hygiene products that offer improved fluid management and breathability for better skin health. Ingeo’s inherent hydrophilic properties result in nonwovens that require less surface finish and have better durability compared to polypropylene. Significant improvements are also seen in both the soak surface tension results and the multiple strike performance. Castor Oil – PLA-nonwovens – Textiles

NatureWorks’ Ingeo biopolymer has a 62% smaller carbon footprint than polypropylene from its manufacturing alone, offering a low carbon alternative to petrochemical based materials. Making Ingeo begins when plants capture and sequester CO2, transforming it into long-chain sugar molecules. NatureWorks then ferments those sugars to make lactic acid, which becomes the building block of a wide array of high-performance materials under the Ingeo brand.

-What are the benefits of the eu packaging regulation?

On 30 November 2022, the European Commission presented the draft for new Europe-wide rules for packaging. Less waste, more recycled material, reusable instead of disposable and a stronger circular economy are the goals. What do the proposals mean for ALPLA and the world of plastics, and where do we still need clarification and improvements?

Climate neutrality by 2050 and circular economy instead of patchwork: In future, uniform rules for packaging are to apply in all EU countries. Strict guidelines and bans are designed to reduce waste, increase the use of post-consumer recycled materials (PCR) and promote recyclable and refillable solutions. The EU Commission presented the draft of the new EU Packaging Regulation to Parliament and the Council on 30 November 2022 – the legally valid regulation is to follow in mid-2024. Countries such as Austria and Germany have already begun implementing proposals such as uniform collection systems for lightweight packaging made of plastic, metal and composites, deposit systems for beverage bottles or reusable take-away obligations. Castor Oil – PLA-nonwovens – Textiles

ALPLA already set itself its own goals in 2018: to process only fully recyclable packaging solutions by 2025 and at least 25% PCR material. With these ambitious goals and successful projects such as reusable PET and bottles made of 100 percent recycled material, the company is already anticipating many things. The plastics specialist welcomes the EU’s proposal and at the same time sees a need for correction.

Quotas and bans

By 2030, all packaging should be recyclable and economically recycled in the EU. To this end, the need for primary raw materials is to be reduced and the market for secondary raw materials strengthened through a Europe-wide quota for the use of PCR material in plastic packaging. For PET packaging for food and pharmaceutical products as well as for disposable plastic beverage bottles, it is 30 percent, for food-grade non-PET plastic packaging 10 percent and for all other plastic packaging 35 percent. By 2040, these quotas are to rise significantly again. Then 50 percent applies to plastic packaging for food and pharmaceutical products and 65 percent to disposable plastic beverage bottles and all other plastic packaging. Castor Oil – PLA-nonwovens – Textiles

Reusable packaging is also to be promoted through quotas and binding deposit systems. In the future, beverages and food must also be offered in reusable or refillable packaging. For hot and cold drinks consumed immediately, the minimum requirements are 20 percent, for take-away dishes and beverages 10 percent – by 2030. From 2040, it will be 80 and 40 percent, respectively. Unnecessary disposable packaging for fruit and vegetables should be banned immediately, miniature packaging in hotels from 2030. The EU is declaring war on oversized packaging by limiting the empty volume to 40 percent. Through an EU-wide labelling obligation, all packaging should provide clear information about material, collection and disposal. In addition, the EU wants to introduce rules for the use, design, disposal and recycling of compostable plastics such as coffee capsules, tea bags or fruit labels. With all these measures, the EU expects a reduction in emissions from 2030 to 66 million tonnes by 43 and a waste reduction of 5 percent – by 2040 it should even be 15 percent.

Tunnel vision on plastics

ALPLA supports the proposal, but points to blind spots. “With sustainable solutions made of plastic, we are making a contribution to climate targets. For a truly ecological circular economy and fair competition, however, all materials must be included,” says Volker Glöckner, Public Affairs and Circular Economy Specialist at ALPLA. ALPLA is therefore calling for equal treatmen t for minimum quotas for production and recycling as well as deposit systems. Castor Oil – PLA-nonwovens – Textiles

This also applies to the calculation of EPR fees (Extended Producer Responsibility), which producers must pay to collection and recovery systems on the basis of criteria of recyclability and possibly also the recycled content. In addition to considering all materials, ALPLA proposes the inclusion of the CO2e-footprint.

-Italy: Production ticks up 4.9% in 2022, turnover exceeds forecast / Orders, revenue expected to rise in 2023

Italy’s plastics and rubber technology industry generated a turnover totaling EUR 4.67 bn last year, a 5% year-on-year markup versus 2021, and exceeded the EUR 4.5 bn forecast made in December, according to industry association Amaplast (Milan; www.amaplast.org).

The main driver of growth is exports, which showed a particularly positive trend towards the end of the year. It had reached EUR 3.25 bn for the whole of 2022, up 8.7%. The domestic market was 0.8% or nearly flat at EUR 2.54 bn.

Total production expanded 4.9% to EUR 4.67 bn, of which 70% were exported. Sales to the Americas improved 12%, with those to South America and Mexico registering the biggest jump; US deliveries have slowed somewhat, declining 3%.

In Asia, where sales climbed 9%, India, Saudi Arabia, and the Emirates were the driving forces. Exports to China fell 7% while deliveries to the EU advanced 8%.

Among the top 10 destinations, Germany stood out with EUR 422.65 mn.

t accounted for 13% of Italy’s total exported value and represented a 14.6% gain versus 2021. Castor Oil – PLA-nonwovens – Textiles

The US was second but sales worth EUR 346.62 mn meant a 3.2% drop.

Machines for primary processing were the most saleable categories, with robust growth in extruders (up 23%), and mono-multifilament systems (up 58%). The latter product registered a steep acceleration of sales from EUR 74 mn in 2020 to EUR 140 mn last year after the previous decade averaged EUR 30-50 mn.

-Andritz Partners with Pellenc ST, Nouvelles Fibres Textiles

Companies establish first industrial-scale automatic textile sorting line in France

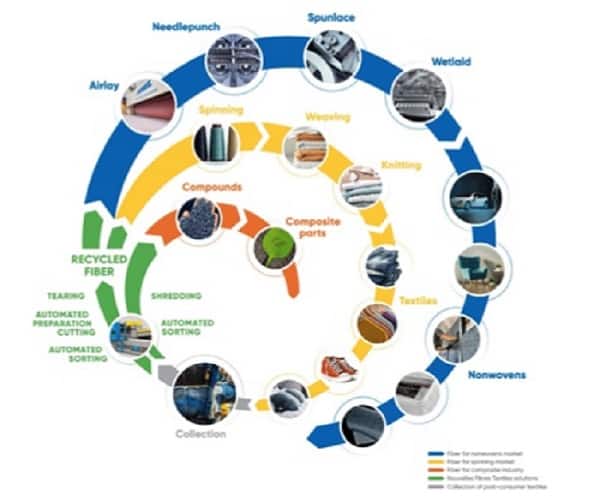

International technology group Andritz has entered an ambitious partnership with Pellenc ST and Nouvelles Fibres Textiles to set up the very first industrial-scale automatic textile sorting line in France combining automated sorting and recycling technology.

The partners have expert knowledge from decades of experience in sorting technologies (Pellenc ST), textile machinery and processes (Andritz), as well as post-consumer textile value chains from sorting to manufacturing (Nouvelles Fibres Textiles newly founded by Les Tissages de Charlieu and Synergies TLC). Castor Oil – PLA-nonwovens – Textiles

The new textile sorting line being built is the first to combine Pellenc ST’s automated sorting technologies with Andritz’s recycling technologies. It will process post-consumer textile wastes to produce recycled fiber engineered for the spinning, nonwoven and composite industries. Starting operations in mid-2023, it will serve as a production line for Nouvelles Fibres Textiles, as an R&D line for the three partners, and as a test and demonstration center for their customers.

Nouvelles Fibres Textiles aims to become a reference in both industrial grade material production and industrial scale post-consumer textile sorting, thanks to innovative technologies with hard point removal providing pure fibers, selective colors, and differentiated fiber types.

Nouvelles Fibres Textiles’ partners also work closely together in R&D at the Andritz Laroche and Pellenc ST technical centers to keep pushing technical boundaries.

Eric Boël, President, Nouvelles Fibres Textiles, comments: “We are very proud to announce the launch of the Nouvelles Fibres Textiles partnership. Several years of R&D involving key players from both textile and household waste management industries made this possible. We all shared our knowledge and expertise to promote on-the-ground circularity for textiles by full integration of the value chain. Castor Oil – PLA-nonwovens – Textiles

-Battery recycling: Bosch to Develop Europe’s First Fully Automated Battery-Discharging Plant

More and more electric cars are finding their way onto the road. Bosch estimates that they will account for around 70 percent of all newly registered passenger cars in Europe by 2030. This is increasing demand for batteries and for the recycling of the raw materials they contain, such as lithium, cobalt, and nickel. Bosch has developed special machinery, equipment, and software for this purpose.

The subsidiary Bosch Rexroth is supplying Battery Lifecycle Company, a joint venture between REMONDIS subsidiary TSR Recycling and Rhenus Automotive, with Europe’s first fully automated system for discharging and disassembling battery modules.

Electromobility can only establish itself in the long term if sufficient raw materials are available for battery production. Castor Oil – PLA-nonwovens – Textiles

“Recycling plays a key role here, and helps place our output on a sustainable footing: we reuse what we use, and we recover raw materials.”

Experts predict that by 2030, Europe will require recycling capacity for up to 420,000 metric tons of battery material each year (Source: Fraunhofer ISI, 2023). “If we want to build a European circular economy, we need to integrate recycling firmly into the product life cycle and create the necessary infrastructure to do so. Bosch is contributing its technical expertise to this,” Hartung says. Bosch will present industrial technology for battery recycling at Hannover Messe (April 17–21, 2023).

Efficient recycling as a building block of a circular economy

Growing numbers of electric cars combined with limited resources and increasing legal requirements for recycling – the challenges are increasing.