Renewable PET Preform

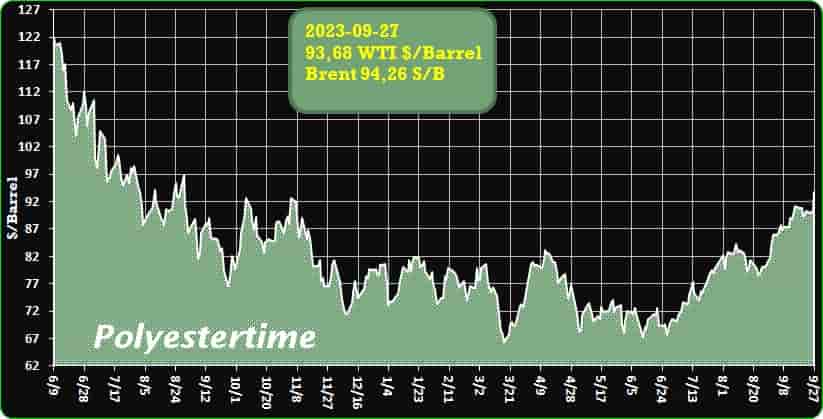

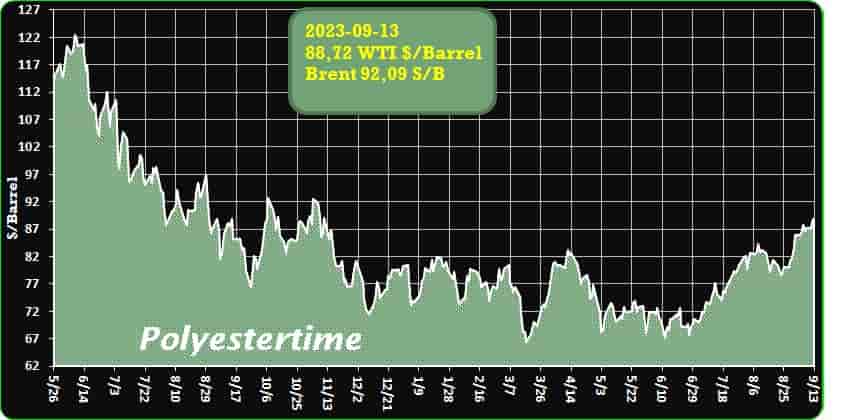

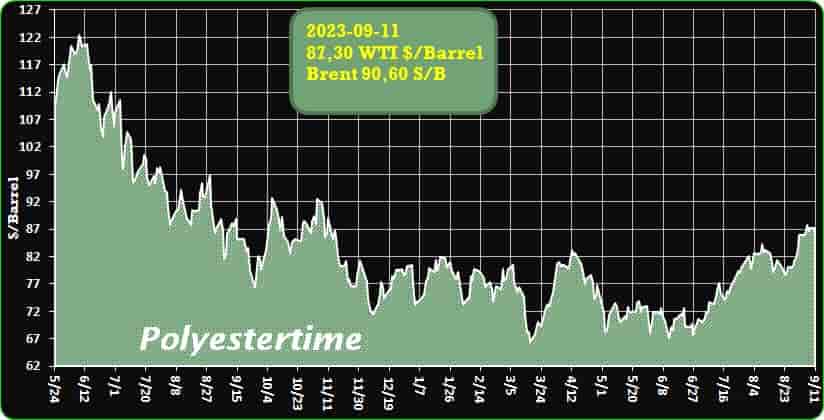

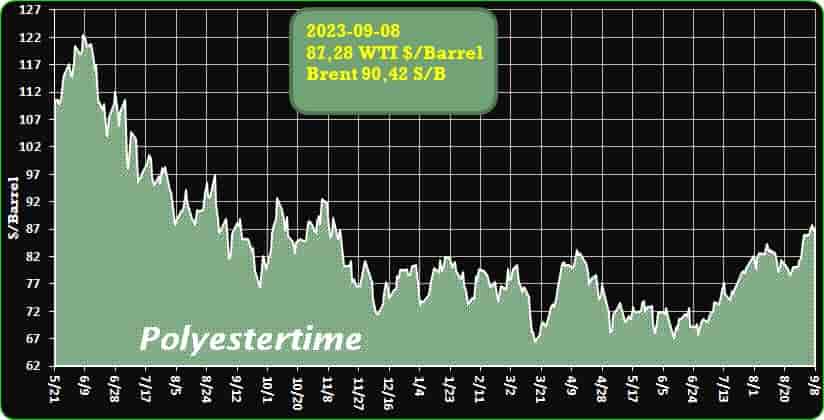

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

RadiciGroup showcased its cutting-edge, secure, and eco-friendly offerings at Plast

RadiciGroup High Performance Polymers is making its presence felt at Plast 2023, a significant event running from September 5 to 8 at the Milano Rho fairgrounds. Positioned in Hall 9, Stand B21-C22, the Group is unveiling a range of innovative solutions tailored to numerous application sectors. These sectors span automotive and e-mobility, electrical/electronics, water management, and consumer and industrial goods.

Central to RadiciGroup’s research and development strategy is the ecological transition. With its vertically integrated polyamide production and over four decades of experience as an engineering polymers manufacturer, the Group is at the forefront of expanding its solutions portfolio. This expansion aims to meet the growing demand for sustainability and circularity while maintaining a strong focus on performance and safety.

Erico Spini, the global marketing director of RadiciGroup High Performance Polymers, emphasized the Group’s commitment to three key fronts. Renewable PET Preform

First, producing materials with superior technical characteristics for metal replacement and lightweighting of components. Second, engaging in mechanical recycling of materials sourced from pre- and post-consumer sources to support the circular economy. And third, incorporating biobased raw materials from renewable sources. These challenges are met head-on thanks to the expertise of RadiciGroup’s personnel and the vast experience accumulated across various sectors and geographic markets.

At the Plast fair, RadiciGroup is showcasing several case histories of finished products achieved through collaboration with customers. These examples illustrate how RadiciGroup’s materials have positively impacted technical and environmental performance. Some highlights include an innovative e-bike rear swing arm developed in partnership with Acerbis and Fantic, an office chair crafted by Bock using Renycle® recycled polyamide, and an electric car charging cable plug and socket created by Gewiss, also using Renycle®. Renewable PET Preform

Intriguingly, the development of an e-bike rear swing arm underscores RadiciGroup’s dedication to metal replacement. This shift towards lightweight, high-performance materials is essential for improving the efficiency and sustainability of transportation.

Furthermore, the use of Renycle® recycled polyamide in an office chair showcases RadiciGroup’s commitment to the circular economy. By recycling materials from pre- and post-consumer sources, the Group demonstrates its dedication to reducing waste and conserving resources while providing quality materials for various applications.

The electric car charging cable plug and socket, also made using Renycle®, exemplifies RadiciGroup’s focus on sustainability. The automotive industry’s shift towards electric vehicles necessitates environmentally friendly materials that maintain safety and performance standards. Renewable PET Preform

To delve deeper into RadiciGroup’s new products and proposals, a press conference titled “RadiciGroup, innovation and sustainability partner: tailor-made solutions for successful projects in every industry sector” is scheduled for September 6 at 2:30 pm at the RadiciGroup stand in Hall 9, Stand B21-C22. This conference promises to provide comprehensive insights into RadiciGroup’s ongoing commitment to innovation, sustainability, and meeting the unique needs of clients across diverse industries.

In conclusion, RadiciGroup High Performance Polymers’ presence at Plast 2023 highlights its dedication to innovation, sustainability, and customized solutions. As industries increasingly prioritize eco-friendly materials and circular practices, RadiciGroup’s expertise and product offerings position it as a valuable partner for businesses across various sectors seeking to thrive in an evolving, sustainable future. Renewable PET Preform

“Retal Expands Portfolio with Popular Monolayer Preform”

Retal, a multinational plastic packaging producer, has enriched its product portfolio with the addition of a highly sought-after monolayer preform, known as the 26/22 GME30.37. This versatile preform is now part of the offerings at Retal Czech, situated in Melnik, and is available in both transparent PET monolayer and PET with additives, catering to the specific needs of each customer. The preform comes in various weight options and is ideally suited for the European markets, particularly in countries like the Czech Republic, Slovakia, Poland, France, and parts of Spain. It serves as a perfect fit for carbonated and non-carbonated beverages that utilize this neck finish.

Jiri Nydrle, Sales Manager at Retal Czech, sheds light on the significance of adding this popular preform to their product range, stating, “This recent addition marks an expansion of our product line to meet the demands of both local and neighboring European customers. Our skilled and experienced team is committed to collaborating with customers to develop tailored packaging solutions for various applications, whether it’s for food, beverages, cosmetics, household items, or industrial products. We offer a wide range of specialized and customizable neck finishes, including 34/29 and 28mm double-start and 17-63mm options. By introducing the production of the 26/22 GME30.37 preform, we’re offering our customers even more choices for a comprehensive packaging solution from a single partner.” Renewable PET Preform

As the demand for carbonated, non-carbonated, and functional beverages continues to rise, it’s imperative to have suitable packaging solutions that are consumer-friendly and environmentally responsible. To address the diverse requirements of each beverage type, Retal Czech can leverage the ongoing research and development efforts at the company’s Lithuanian design laboratory. Here, state-of-the-art CAD design software is utilized, and a highly skilled R&D team meticulously analyzes even the smallest changes and their impact.

Andzejus Buinovskis, a member of the creative team at Retal’s R&D lab in Lithuania, explains how the 26/22 neck finishes differ, with key distinctions in weight, neck height, and application. Buinovskis notes, “In all our work, we focus on making impactful improvements without compromising performance. Sustainability is always a priority, so the weight of the preform is critical, while ensuring it maintains its structural integrity and practicality. The 26/22 GME30.40 stands out with its ample tether parking space compared to other 26/22 neck finishes, ensuring a wide opening angle and excellent functionality for the tethered cap.” Renewable PET Preform

Retal’s ability to provide expert technical knowledge sets it apart in the packaging industry. By staying attuned to industry trends and the evolving legislative requirements in various markets, the company has already commenced production of 23.5g and 26.5g 26/22 GME30.37 preforms in 1.5-liter to 2-liter sizes for a well-regarded local beverage brand in Slovakia, Poland, and Germany, with ongoing testing for additional customers.

Jiri Nydrle concludes, “This is an exciting period for preform development, both for us and our customers. We must navigate the changing legislative landscape, and for that, we are fortunate to have the expertise of our R&D team. It’s also a significant advancement for our industry. Being able to offer sustainable options from our Melnik plant is a win for our local and neighboring customers. We have a diverse range of solutions available, with varying weights, neck finishes, and applications. Renewable PET Preform

Visit Retal to learn more about their offerings.

Inflation in Turkey Surges to 59%: A Looming Economic Crisis

Turkey finds itself in the throes of a crippling economic challenge as its inflation rate surged to an alarming 58.9% year-on-year in August, marking the highest level since December 2022. Official data, released on a fateful Monday, revealed the disconcerting reality of the country’s economic landscape. This abrupt and relentless spike in prices has cast a shadow over the daily lives of Turkish citizens, posing a monumental threat to their livelihoods.

The magnitude of this crisis becomes even more evident when we consider the stark contrast with the previous year. Prices in August 2023 had soared nearly 60% compared to the same period in 2022. Furthermore, the month-on-month increase was a staggering 9.1%, primarily fueled by the rapid depreciation of the Turkish lira. The economic repercussions of this inflationary surge are profound, affecting the affordability of basic necessities and the overall well-being of the populace. Renewable PET Preform

The recent trajectory of inflation in Turkey paints a disheartening picture. For eight consecutive months, from November 2022 to June 2023, there was a glimmer of hope as inflation showed signs of abating. It had reached its lowest point in a year and a half, standing at 38.2% year-on-year in June. However, this respite was short-lived, as inflation embarked on a relentless upward spiral in July, reaching 47.8% year-on-year. The rollercoaster ride of inflation rates continued, with a sense of economic uncertainty engulfing the nation.

It is crucial to note that official figures may not fully encapsulate the gravity of the inflation crisis. Independent economists, belonging to the Inflation Research Group (Enag), have sounded an even graver alarm, suggesting that the year-on-year rise in consumer prices could be as high as an astonishing 128%. This disparity between official statistics and independent assessments underscores the pressing need for transparent and comprehensive data reporting. Renewable PET Preform

The Turkish Central Bank, entrusted with the responsibility of safeguarding price stability, has taken drastic measures to combat the inflationary surge. Since June, the bank has aggressively increased its main key interest rate from 8.5% to a staggering 25%. These unprecedented rate hikes were implemented in a bid to curb the runaway inflation that threatened to cripple the Turkish economy.

As early as the end of July, when inflation began its resurgence, the central bank revised its inflation forecasts, projecting that it would reach an alarming 58% by the close of 2023. This projection represents more than double the previous estimates, underscoring the severity of the situation. The central bank anticipates a prolonged battle to restore economic stability, with the hope of achieving it only by 2025.

The repercussions of Turkey’s prolonged bout with double-digit inflation since late 2019 are felt across the country. Families are grappling with the daunting cost of living, and the sustainability of their basic needs is at risk. The relentless rise in prices has eroded the purchasing power of the Turkish lira, making it increasingly challenging for households to make ends meet. Renewable PET Preform

In conclusion, Turkey stands at a critical juncture in its economic history, grappling with an inflation crisis of unprecedented proportions. The surge in consumer prices has left the populace struggling to maintain their standard of living, with no immediate relief in sight. The Turkish government, in tandem with the Central Bank, faces the monumental task of stabilizing the economy and ensuring the well-being of its citizens in the face of this daunting economic challenge.

ZF prepares next-gen electric motor free from magnets

ZF is in the process of developing an advanced electric motor devoid of magnets. Unlike existing magnet-free designs for externally excited motors, ZF’s innovative I2SM model generates the magnetic field’s energy through an inductive exciter housed within the rotor shaft.

According to ZF, this solution promises to deliver an exceptionally compact design while maximizing power and torque density. Similarly, an externally excited synchronous motor (FSM) also eliminates the need for permanent magnets or rare earth materials.

Through the development of the In-Rotor Inductive-Excited Synchronous Motor (I2SM), ZF aims to create motors that are not only highly sustainable in production but also incredibly powerful and efficient during operation. ZF claims that the performance of the I2SM is on par with permanent-magnet synchronous machines. Renewable PET Preform

Conventional FSM systems, although magnet-free, still require sliding or brush components to transmit current to the rotating rotor, which limits their installation possibilities. However, the compact I2SM eliminates this limitation, enabling what ZF refers to as “space-neutral integration” of the exciter into the rotor, thereby avoiding axial space constraints. Additionally, the I2SM boasts increased power density in the rotor and does away with the need for loops, brushes, or extra seals.

In comparison to traditional FSM systems, the inductive exciter of the I2SM is claimed to reduce energy transfer losses to the rotor by 15 percent. Furthermore, in production, it can potentially reduce the CO2 footprint by up to 50 percent when compared to permanent magnet synchronous motors, which require substantial energy for magnet production.

ZF intends to advance the I2SM technology to the point of production readiness, though a specific timeline remains undisclosed. Once ready, it will be offered as an option within ZF’s e-drive product lineup. Customers will have the choice between 400-volt and 800-volt architectures suitable for both passenger and commercial vehicles. The latter will employ silicon carbide chips in the power electronics. Renewable PET Preform

Dr. Holger Klein, CEO of ZF, emphasizes the company’s commitment to innovation that enhances the sustainability, efficiency, and resource conservation of electric drives, highlighting their magnet-free e-motor as a prime example. Development board member Stephan von Schuckmann lauds the drive as a demonstration of ZF’s strategy to enhance resource efficiency and sustainability in e-drives, primarily through efficiency improvements.

Brazil’s focus has shifted towards sugar production at the expense of ethanol output

In the upcoming 2023/24 season (April-March), Brazil anticipates its highest-ever sugar production, with record-breaking export volumes of the sweetener, according to Hydrocarbonprocessing.

Brazil’s overall sugar production, spanning all producing regions, is now estimated at 42.7 million metric tons. This exceeds Job Economia’s initial forecast by 2.3 million tons and surpasses the 37 million tons produced in the previous season (2022/23). Ideal weather conditions this season have greatly benefited crop growth and processing.

Julio Maria Borges, managing partner at Job Economia, expressed optimism, stating, “So far so good for the season, very good.” The consultancy has upgraded its predictions for sugarcane processing and sugar production in both the Centre-South and Northeast regions of Brazil. It foresees exports reaching an all-time high of 32.2 million tons in the season, an increase of 2.4 million tons compared to its earlier estimate and a significant rise from the 27.1 million tons exported in 2022/23. Renewable PET Preform

Borges noted, “That will account for around 50% of the global trade of sugar.” This surge in Brazil’s projected production and sugar exports aligns with adverse weather conditions affecting sugar-producing competitors such as India and Thailand, which are expected to have limited export quantities.

In Brazil, sugar mills are diverting a nearly record-breaking amount of sugarcane towards sugar production, while ethanol production is being curtailed due to higher prices for sugar. Job Economia’s projection for total ethanol output now stands at 32.9 billion liters, which is 600 million liters less than their initial estimate. In the previous season, Brazil produced 31.2 billion liters of ethanol.

However, the portion of ethanol derived from corn is expected to grow by 25% this season, reaching 5.5 billion liters. This corn-based ethanol already constitutes 20% of the country’s total ethanol production, a significant shift from the previous reliance on sugarcane alone.

Kelheim Fibres and MagnoLab Unite for Textile Advancement and Eco-Friendliness

Kelheim Fibres, a leading manufacturer of specialized viscose fibers, has forged a strategic partnership with MagnoLab, an international consortium of textile industry companies situated in the Biella region. This collaboration underscores the significance of inter-company cooperation in propelling innovation and sustainability within the textile sector. Kelheim Fibres, renowned for pioneering sustainable viscose fibers, positions itself not merely as a fiber supplier but as an innovation collaborator for the entire industry. Employing an Open Innovation approach, Kelheim Fibres actively encourages the exchange of ideas and knowledge to jointly conceive sustainable solutions for the future.

Kelheim Fibres operates a range of in-house pilot and technical facilities. This close-knit alliance with MagnoLab, distinguished by its cutting-edge textile machinery, enhances the efficiency of research and development efforts. Renewable PET Preform

Dr. Marina Crnoja-Cosic, Director of New Business Development, Marketing & Communications at Kelheim Fibres, underscores the benefits of this partnership: “By closely connecting with the companies under the MagnoLab umbrella, we can produce small-scale samples and prototypes employing diverse technologies. This empowers us to craft solutions grounded in our specialized fibers, which can seamlessly integrate into our partners’ textile value chain.”

Giovanni Marchi, President of MagnoLab, echoes his enthusiasm: “Kelheim Fibres represents our inaugural collaboration with a fiber manufacturer. Together, we now span the entire textile spectrum, elevating the value of our collective work. This collaboration facilitates practical testing, expediting the implementation of innovations. It also fosters tighter integration within the European (and thus regional) value chain. Reduced transport distances across Europe not only diminish environmental impacts but also streamline innovation realization on the continent.” Renewable PET Preform

More…

China’s Economic Challenges: Services PMI Disappoints Markets, Country Garden’s Bond Payments

China’s economic landscape is facing turbulence as the services Purchasing Managers’ Index (PMI) disappoints the markets, triggering a downward spiral in various sectors. On Tuesday, September 5, Asian markets experienced fluctuations, with the Nikkei slightly above parity, the Hang Seng losing 1.5%, and Shanghai down by 0.65%. Simultaneously, futures on Wall Street remained slightly down, anxiously awaiting afternoon data on factory orders.

The Chinese government’s recent measures to bolster the real estate sector and consumer spending, though significant, have not yet instilled confidence among investors, leading to a retreat from riskier assets. As China grapples with its economic challenges, the real estate giant, Country Garden, came under scrutiny after a 2% drop in its stock on Tuesday. This setback followed a rebound in the previous session, despite news that the company managed to make last-minute coupon payments on dollar-denominated bonds, which had expired a month ago. Remarkably, these payments came after investors had pardoned the company on seven yuan-denominated bonds whose redemption had been postponed. Renewable PET Preform

The disappointment in China’s economic performance can be largely attributed to the underwhelming data from the Caixin China General Service PMI. In August 2023, the PMI fell to 51.8 from July’s 51.9, missing market expectations of 53.6. This drop marked the weakest increase in services activity since the start of the year, reflecting mounting downward pressure on the economy. The slowing growth in new orders and a decline in overseas sales, the first since December of the previous year, contributed to this downturn. Furthermore, sentiment hit a nine-month low, underlining the concerns pervading the business community.

In this context, the Reserve Bank of Australia’s decision to maintain its interest rates at 4.1% during its September meeting is notable. This move represents the third consecutive month in which the bank has opted to keep rates steady, aligning with market consensus. The central bank stated that inflation had peaked but remained unacceptably high, with expectations that it would persist for some time. It reiterated that further monetary tightening might be necessary to bring inflation back within the 2-3% target range in a reasonable timeframe. The decision to adjust rates would hinge on the evolution of the economy and prices. The bank’s forecasts indicate an expected inflation rate of around 3.25% by the end of 2024, with a return to the expected corridor by the end of 2025. However, Australia’s economy is currently experiencing below-trend growth, with a gradual rise in unemployment expected to reach approximately 4.5% by the end of the following year. Renewable PET Preform

Meanwhile, the spotlight is on China’s largest private real estate developer, Country Garden, as it made interest payments on two dollar-denominated bonds within the grace period, which expires 30 days after the bond issue. The failure to pay $22.5 million in coupons due on August 6 had raised concerns about the extent of the Chinese government’s economic stimulus to stabilize the housing market—a sector that accounts for approximately 28% of the national GDP. The uncertainty surrounding the bond payments added to the unease in China’s financial landscape and sparked questions about the government’s ability to manage its economic challenges effectively.

In conclusion, China faces mounting economic challenges as its services PMI falls below expectations and investor confidence wavers. The government’s efforts to bolster the real estate sector and consumer spending have not yet yielded the desired results. The situation is further compounded by the concerns surrounding Country Garden’s bond payments. Renewable PET Preform

These developments underscore the complexity of China’s economic landscape and the need for strategic and comprehensive measures to navigate the challenges ahead.

Closed-Loop PET Tray – A novel type of plastic that possesses the remarkable ability to biodegrade completely on its own 05-09-2023

Renewable PET Preform